Information injection-pump assembly

BOSCH

9 400 615 423

9400615423

ZEXEL

101606-1030

1016061030

MITSUBISHI

ME050822

me050822

Rating:

Service parts 101606-1030 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Include in #1:

101606-1030

as INJECTION-PUMP ASSEMBLY

Include in #2:

104746-6120

as _

Cross reference number

BOSCH

9 400 615 423

9400615423

ZEXEL

101606-1030

1016061030

MITSUBISHI

ME050822

me050822

Zexel num

Bosch num

Firm num

Name

101606-1030

9 400 615 423

ME050822 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D22 * K 14BF INJECTION PUMP ASSY PE6AD PE

6D22 * K 14BF INJECTION PUMP ASSY PE6AD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-4620

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.5

4.45

4.55

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

9.2

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

101

99

103

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

7.6+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

17.5

14.9

20.1

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Timer adjustment

Pump speed

r/min

800+120

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1000

Advance angle

deg.

0.9

0.4

1.4

Timer adjustment_03

Pump speed

r/min

1100

Advance angle

deg.

2.5

2

3

Timer adjustment_04

Pump speed

r/min

-

Advance angle

deg.

4

4

5

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

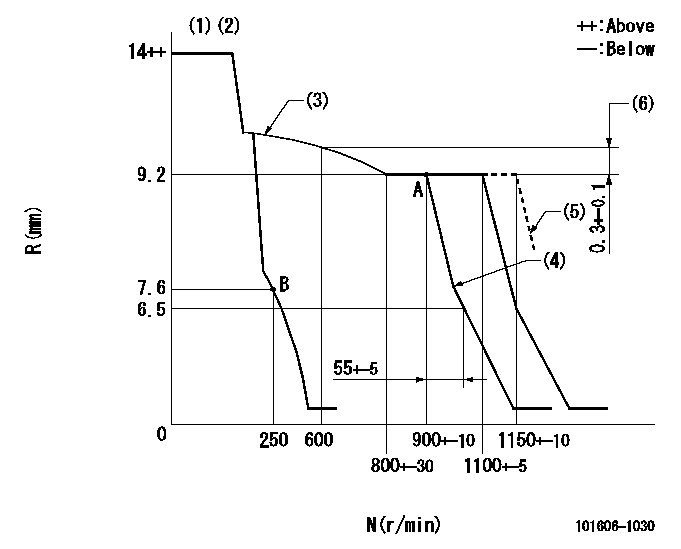

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Supplied with torque spring not set.

(3)The torque control spring must does not have a set force.

(4)Idle sub spring setting: L1.

(5)At shipping

(6)Rack difference between N = N1 and N = N2

----------

K=15 L1=7.3+-0.1mm N1=900r/min N2=600r/min

----------

----------

K=15 L1=7.3+-0.1mm N1=900r/min N2=600r/min

----------

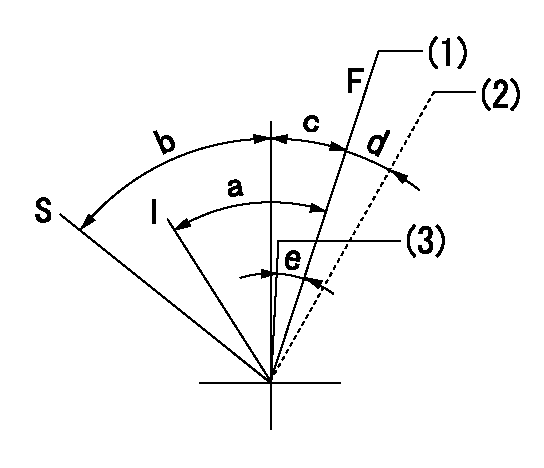

Speed control lever angle

F:Full speed

I:Idle

S:Stop

(1)Pump speed = aa

(2)At shipping

(3)Pump speed = bb

----------

aa=1100r/min bb=900r/min

----------

a=25deg+-5deg b=32deg+-3deg c=10deg+-5deg d=(2deg) e=7deg+-5deg

----------

aa=1100r/min bb=900r/min

----------

a=25deg+-5deg b=32deg+-3deg c=10deg+-5deg d=(2deg) e=7deg+-5deg

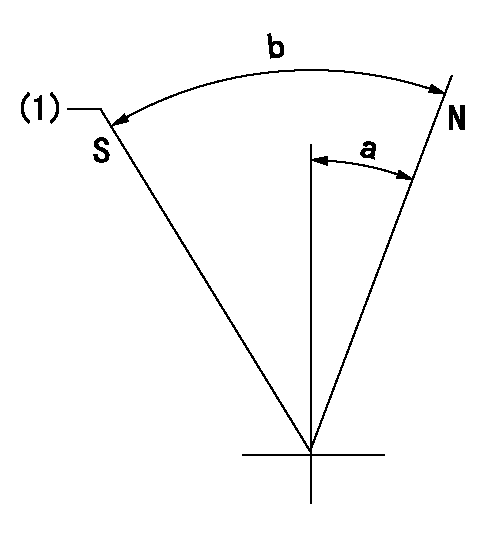

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)At shipping

----------

----------

a=39deg+-5deg b=53deg+-5deg

----------

----------

a=39deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(7deg)

----------

----------

a=(7deg)

Information:

Literature Information

This Manual contains safety, operation instructions, lubrication and maintenance information. Read - study - and keep it with the truck/vehicle literature and engine information.Some photographs or illustrations in this Manual show details or attachments that may be different from your engine. Guards and covers may have been removed for illustrative purposes.Continuing improvement and advancement of product design may have caused changes to your engine which are not included in this Manual.Whenever a question arises regarding your engine, or this Manual, please consult Caterpillar for the latest available information.Safety

The safety section lists basic safety precautions. In addition, this sectio identifies hazardous, warning situations. Read and understand the basic precautions listed in the safety section before operating or performing lubrication, maintenance and repair on this product.Operation

The operation section is a reference for operators and photographs and illustrations guide the operator through correct procedures of inspecting, starting, operating and stopping the engine. This section also includes a discussion of gauges, protection devices, engine controls and lifting and storage information.Maintenance

The maintenance section is a guide to engine care. The illustrated, step-by-step instructions are grouped by Preventive Maintenance servicing intervals. Items in the Maintenance Schedule are referenced to detailed instructions that follow. Maintenance Intervals are listed for "ideal" operating conditions of vehicles on paved roads in good condition and at average travel speeds. Maintenance Intervals must be reduced when operating in adverse conditions. Refer to the Maintenance Reduction Factors in the Maintenance Section of this Manual for information.Recommended service should always be performed at the interval that occurs first. More frequent maintenance checks than specified in the Maintenance Schedule will be necessary when operating under very severe, dusty or freezing cold operating conditions. Refer to the Severe Service Application topics in this Manual for the information.Overhaul

Major engine repair such as overhaul is not covered in this Manual except for the overhaul interval and the maintenance items in that interval. Major repairs are best left to the trained personnel of Caterpillar. Caterpillar offers a variety of options regarding overhaul programs. If you experience a major engine failure which necessitates removal of the engine from the chassis, there are numerous after failure overhaul options available.

This Manual contains safety, operation instructions, lubrication and maintenance information. Read - study - and keep it with the truck/vehicle literature and engine information.Some photographs or illustrations in this Manual show details or attachments that may be different from your engine. Guards and covers may have been removed for illustrative purposes.Continuing improvement and advancement of product design may have caused changes to your engine which are not included in this Manual.Whenever a question arises regarding your engine, or this Manual, please consult Caterpillar for the latest available information.Safety

The safety section lists basic safety precautions. In addition, this sectio identifies hazardous, warning situations. Read and understand the basic precautions listed in the safety section before operating or performing lubrication, maintenance and repair on this product.Operation

The operation section is a reference for operators and photographs and illustrations guide the operator through correct procedures of inspecting, starting, operating and stopping the engine. This section also includes a discussion of gauges, protection devices, engine controls and lifting and storage information.Maintenance

The maintenance section is a guide to engine care. The illustrated, step-by-step instructions are grouped by Preventive Maintenance servicing intervals. Items in the Maintenance Schedule are referenced to detailed instructions that follow. Maintenance Intervals are listed for "ideal" operating conditions of vehicles on paved roads in good condition and at average travel speeds. Maintenance Intervals must be reduced when operating in adverse conditions. Refer to the Maintenance Reduction Factors in the Maintenance Section of this Manual for information.Recommended service should always be performed at the interval that occurs first. More frequent maintenance checks than specified in the Maintenance Schedule will be necessary when operating under very severe, dusty or freezing cold operating conditions. Refer to the Severe Service Application topics in this Manual for the information.Overhaul

Major engine repair such as overhaul is not covered in this Manual except for the overhaul interval and the maintenance items in that interval. Major repairs are best left to the trained personnel of Caterpillar. Caterpillar offers a variety of options regarding overhaul programs. If you experience a major engine failure which necessitates removal of the engine from the chassis, there are numerous after failure overhaul options available.

Have questions with 101606-1030?

Group cross 101606-1030 ZEXEL

Mitsubishi

101606-1030

9 400 615 423

ME050822

INJECTION-PUMP ASSEMBLY

6D22

6D22