Information injection-pump assembly

BOSCH

F 019 Z10 735

f019z10735

ZEXEL

101606-0600

1016060600

ISUZU

1156035100

1156035100

Rating:

Service parts 101606-0600 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

16.7(170)/19.6(200)

14.

NOZZLE

Include in #1:

101606-0600

as INJECTION-PUMP ASSEMBLY

Include in #2:

104746-6080

as _

Cross reference number

BOSCH

F 019 Z10 735

f019z10735

ZEXEL

101606-0600

1016060600

ISUZU

1156035100

1156035100

Zexel num

Bosch num

Firm num

Name

101606-0600

F 019 Z10 735

1156035100 ISUZU

INJECTION-PUMP ASSEMBLY

6BG1-T K 14BF INJECTION PUMP ASSY PE6AD PE

6BG1-T K 14BF INJECTION PUMP ASSY PE6AD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-4120

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.2

4.15

4.25

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

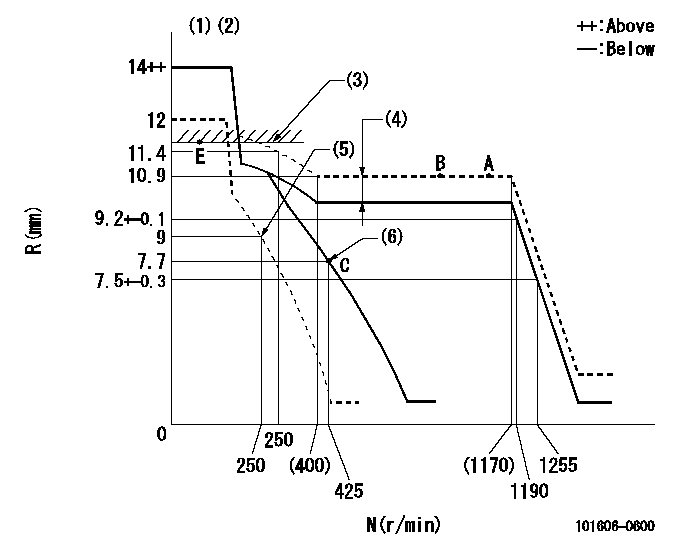

Injection quantity adjustment

Adjusting point

A

Rack position

10.9

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

100

98.5

101.5

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Boost pressure

kPa

93.3

93.3

Boost pressure

mmHg

700

700

Injection quantity adjustment_02

Adjusting point

-

Rack position

8.2+-0.5

Pump speed

r/min

425

425

425

Average injection quantity

mm3/st.

12

10.7

13.3

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

E

Rack position

11.1++

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

80

75

85

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

R1-1.2

Boost pressure

kPa

30.7

26.7

34.7

Boost pressure

mmHg

230

200

260

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

R1(10.9)

Boost pressure

kPa

80

73.3

86.7

Boost pressure

mmHg

600

550

650

Timer adjustment

Pump speed

r/min

1300++

Advance angle

deg.

0

0

0

Remarks

Do not advance until starting N = 1300.

Do not advance until starting N = 1300.

Timer adjustment_02

Pump speed

r/min

-

Advance angle

deg.

1

1

1

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

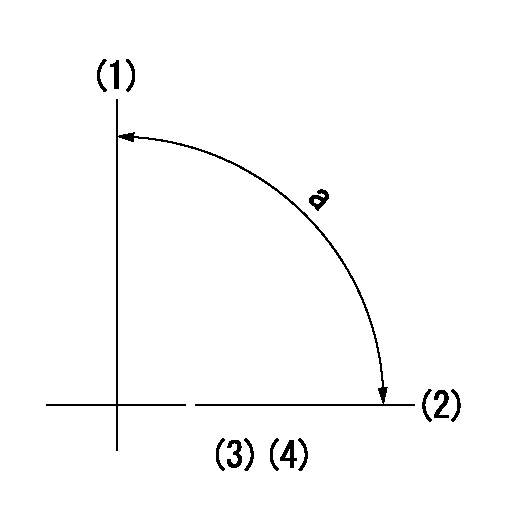

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Boost compensator stroke: BCL

(5)Set idle sub-spring

(6)Main spring setting

----------

K=12 BCL=1.2+-0.1mm

----------

----------

K=12 BCL=1.2+-0.1mm

----------

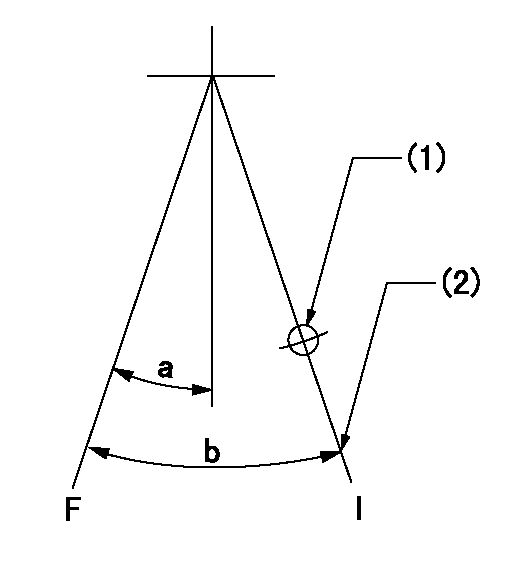

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt setting

----------

aa=70mm

----------

a=12deg+-5deg b=22deg+-5deg

----------

aa=70mm

----------

a=12deg+-5deg b=22deg+-5deg

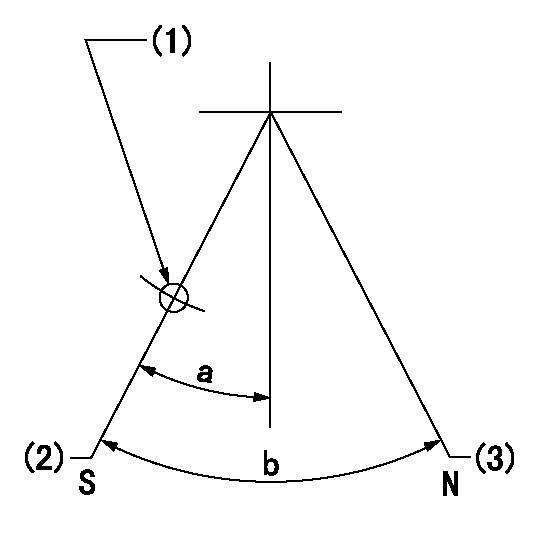

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the hole at R = aa

(2)Rack position bb, pump speed cc (seal at delivery)

(3)Normal

----------

aa=23mm bb=1-0.5mm cc=0r/min

----------

a=32deg+-5deg b=(55deg)

----------

aa=23mm bb=1-0.5mm cc=0r/min

----------

a=32deg+-5deg b=(55deg)

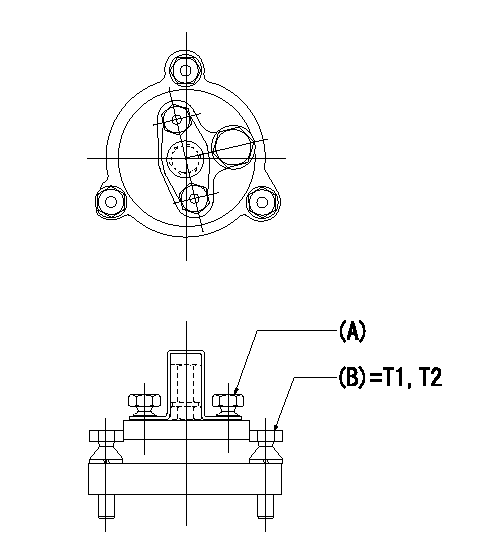

0000001501 TAMPER PROOF

Tamperproofing-equipped boost compensator cover installation procedure

(A): After adjusting the boost compensator, assemble then tighten the bolts to remove the heads.

(B): Specified torque

(1)Before adjusting the governor and the boost compensator, tighten the screw to the specified torque.

(Tightening torque T = T1 maximum)

(2)After adjusting the governor and the boost compensator, tighten to the specified torque to break off the bolt heads.

(Tightening torque T = T2 maximum)

----------

T1=2.5N-m(0.25kgf-m) T2=2.9~4.4N-m(0.3~0.45kgf-m)

----------

----------

T1=2.5N-m(0.25kgf-m) T2=2.9~4.4N-m(0.3~0.45kgf-m)

----------

Timing setting

(1)Pump vertical direction

(2)Positions of coupling's threaded installation holes at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=6deg

----------

a=(90deg)

----------

aa=6deg

----------

a=(90deg)

Information:

Caterpillar Reference Material

Oil

SEBD0640 Oil and Your EngineSEBU6310 EMA Engine Oil Data BookPEDP7105 Scheduled Oil SamplingPEDP7122 Question & Answer BookletPEHP0002 Cat Molybdenum Grease (MPGM)PEHP0003 Cat Lithium Grease (MPGL)PEHP0017 Cat Special Purpose Grease (SPG)PEHP1020 Cat Diesel Engine Oil (CF-4) Data Sheet (North America)PEHP1026 Cat Diesel Engine Oil (CF-4) Data Sheet (International)PEHP6001 How to Take a Good Oil SamplePEWP9733 Cat Fluids SelectorFuel

SEBD0717 Diesel Fuels and Your EngineSEHS7067 Fuels for Caterpillar Diesel EnginesLEKQ3363 Caterpillar Engine Data Sheet 60.1(Fuels Recommended For Use In Caterpillar Truck Engines)Coolant

SEBD0518 Know Your Cooling SystemSEBD0970 Coolant and Your EngineService Manauls

SEBR0514 Low Emission SystemSENR5105 3176 ATAAC Truck Engine Service Manual (7LG1 and Up)SENR5111 3176 ATAAC Truck Engine Schematic Manual (7LG1 and Up)SENR5112 3176 ATAAC Truck Engine Electrical Manual (7LG1 and Up)SENR5110 3176 ATAAC Truck Engine Troubleshooting Manual (7LG1 and Up)SENR5113 3176 ATAAC Truck Engine Mechanical Manual (7LG1 and Up)SENR5114 3176 ATAAC Truck Engine Performance Specifications (7LG1 and Up)SENR5115 3176 ATAAC Truck Engine OEM Systems Manual (7LG1 and Up)SENR5116 3176 ATAAC Truck Engine Jacobs Brake Manual (7LG1 and Up)Parts Manuals

SEBP1954 3176 ATAAC Truck Engine Parts Manual (7LG1 and Up)Special Instructions

SEHS8622 Using the FT1984 Air-To-Air Aftercooler Leak Test GroupSEHS9031 Storage Procedure for Caterpillar ProductsSEHS8884 Unit Injector Test SpecificationsSEHS8746 Using the 1U5540 Tool GroupSEHS8867 Using the 1U6661 Pop (Injector) Tester The following Special Instructions pertain to the operation, maintenance, diagnostic tooling and programming of the 3176 system. Some of these publications will be included in the tool kits, the others will be available thru your Caterpillar dealer.SEHS8741 Using 8C5919 Service Program Module Operating ManualSEHS8743 Using 7X1830 Service Program Module Operating ManualMiscellaneous

SEBF8029 Index to Guidelines for Reusable Parts and Salvage OperationsSEBF8062 Guideline for Reusable Parts - Cleaning and Inspection of Air FiltersSELF5052 Emission Related Components WarrantyLEDT5092 Driving Techniques For Maximum Fuel EconomyLEBT8121 Truck Engine Application and Installation GuideLEGT5087 Truck Engine Application and Installation GuideLEDT4211 PAR DirectoryLEKT8467 Specing for Peak PerformanceAll of the above publications are available through your Caterpillar dealer.Additional Reference Material

ASTM D217-68 - Worked PenetrationASTM D2896 - TBN MeasurementsASTM D2982BASTM D3828AASTM D445ASTM D893ASTM 4985-89 - GM-6038M SpecificationASTM D1384 -Glassware Corrosion TestASTM D2809 -Cavitation Corrosion of Aluminum TestASTM D4340 -Hot Surface Corrosion of Aluminum TestASTM Specs can normally be obtained from your local technological society, library or college.SAE J313 - Diesel FuelsSAE J754 - NomenclatureSAE J183 - ClassificationSAE Specs can be found in your SAE handbook or can be obtained from your local library, college or technological society.* SAE handbooks can be obtained directly from:SAE International

400 Commonwealth Drive

Warrendale, PA USA 15096-0001

All of the above publications are available through your Caterpillar dealer.SAE J313 - Diesel FuelsSAE J754 - NomenclatureSAE J183 - ClassificationSAE Specs can be found in your SAE handbook or can be obtained from your local library, college or technological society.* SAE handbooks can be obtained directly from:SAE International

400 Commonwealth Drive

Warrendale, PA USA 15096-0001

All of the above publications are available through your Caterpillar dealer.

Oil

SEBD0640 Oil and Your EngineSEBU6310 EMA Engine Oil Data BookPEDP7105 Scheduled Oil SamplingPEDP7122 Question & Answer BookletPEHP0002 Cat Molybdenum Grease (MPGM)PEHP0003 Cat Lithium Grease (MPGL)PEHP0017 Cat Special Purpose Grease (SPG)PEHP1020 Cat Diesel Engine Oil (CF-4) Data Sheet (North America)PEHP1026 Cat Diesel Engine Oil (CF-4) Data Sheet (International)PEHP6001 How to Take a Good Oil SamplePEWP9733 Cat Fluids SelectorFuel

SEBD0717 Diesel Fuels and Your EngineSEHS7067 Fuels for Caterpillar Diesel EnginesLEKQ3363 Caterpillar Engine Data Sheet 60.1(Fuels Recommended For Use In Caterpillar Truck Engines)Coolant

SEBD0518 Know Your Cooling SystemSEBD0970 Coolant and Your EngineService Manauls

SEBR0514 Low Emission SystemSENR5105 3176 ATAAC Truck Engine Service Manual (7LG1 and Up)SENR5111 3176 ATAAC Truck Engine Schematic Manual (7LG1 and Up)SENR5112 3176 ATAAC Truck Engine Electrical Manual (7LG1 and Up)SENR5110 3176 ATAAC Truck Engine Troubleshooting Manual (7LG1 and Up)SENR5113 3176 ATAAC Truck Engine Mechanical Manual (7LG1 and Up)SENR5114 3176 ATAAC Truck Engine Performance Specifications (7LG1 and Up)SENR5115 3176 ATAAC Truck Engine OEM Systems Manual (7LG1 and Up)SENR5116 3176 ATAAC Truck Engine Jacobs Brake Manual (7LG1 and Up)Parts Manuals

SEBP1954 3176 ATAAC Truck Engine Parts Manual (7LG1 and Up)Special Instructions

SEHS8622 Using the FT1984 Air-To-Air Aftercooler Leak Test GroupSEHS9031 Storage Procedure for Caterpillar ProductsSEHS8884 Unit Injector Test SpecificationsSEHS8746 Using the 1U5540 Tool GroupSEHS8867 Using the 1U6661 Pop (Injector) Tester The following Special Instructions pertain to the operation, maintenance, diagnostic tooling and programming of the 3176 system. Some of these publications will be included in the tool kits, the others will be available thru your Caterpillar dealer.SEHS8741 Using 8C5919 Service Program Module Operating ManualSEHS8743 Using 7X1830 Service Program Module Operating ManualMiscellaneous

SEBF8029 Index to Guidelines for Reusable Parts and Salvage OperationsSEBF8062 Guideline for Reusable Parts - Cleaning and Inspection of Air FiltersSELF5052 Emission Related Components WarrantyLEDT5092 Driving Techniques For Maximum Fuel EconomyLEBT8121 Truck Engine Application and Installation GuideLEGT5087 Truck Engine Application and Installation GuideLEDT4211 PAR DirectoryLEKT8467 Specing for Peak PerformanceAll of the above publications are available through your Caterpillar dealer.Additional Reference Material

ASTM D217-68 - Worked PenetrationASTM D2896 - TBN MeasurementsASTM D2982BASTM D3828AASTM D445ASTM D893ASTM 4985-89 - GM-6038M SpecificationASTM D1384 -Glassware Corrosion TestASTM D2809 -Cavitation Corrosion of Aluminum TestASTM D4340 -Hot Surface Corrosion of Aluminum TestASTM Specs can normally be obtained from your local technological society, library or college.SAE J313 - Diesel FuelsSAE J754 - NomenclatureSAE J183 - ClassificationSAE Specs can be found in your SAE handbook or can be obtained from your local library, college or technological society.* SAE handbooks can be obtained directly from:SAE International

400 Commonwealth Drive

Warrendale, PA USA 15096-0001

All of the above publications are available through your Caterpillar dealer.SAE J313 - Diesel FuelsSAE J754 - NomenclatureSAE J183 - ClassificationSAE Specs can be found in your SAE handbook or can be obtained from your local library, college or technological society.* SAE handbooks can be obtained directly from:SAE International

400 Commonwealth Drive

Warrendale, PA USA 15096-0001

All of the above publications are available through your Caterpillar dealer.

Have questions with 101606-0600?

Group cross 101606-0600 ZEXEL

Isuzu

101606-0600

F 019 Z10 735

1156035100

INJECTION-PUMP ASSEMBLY

6BG1-T

6BG1-T