Information injection-pump assembly

ZEXEL

101606-0011

1016060011

ISUZU

8943921081

8943921081

Rating:

Cross reference number

ZEXEL

101606-0011

1016060011

ISUZU

8943921081

8943921081

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-4920

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.2

4.15

4.25

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

10.9

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

71

69.4

72.6

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

9.6+-0.5

Pump speed

r/min

275

275

275

Average injection quantity

mm3/st.

9.4

8.1

10.7

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(10.9)

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

71

70

72

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.45

Pump speed

r/min

1425

1425

1425

Average injection quantity

mm3/st.

87.5

83.5

91.5

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

57

53.8

60.2

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

I

Rack position

-

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

125

125

133

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

550--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

500

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1000

Advance angle

deg.

3

2.5

3.5

Remarks

Finish

Finish

Test data Ex:

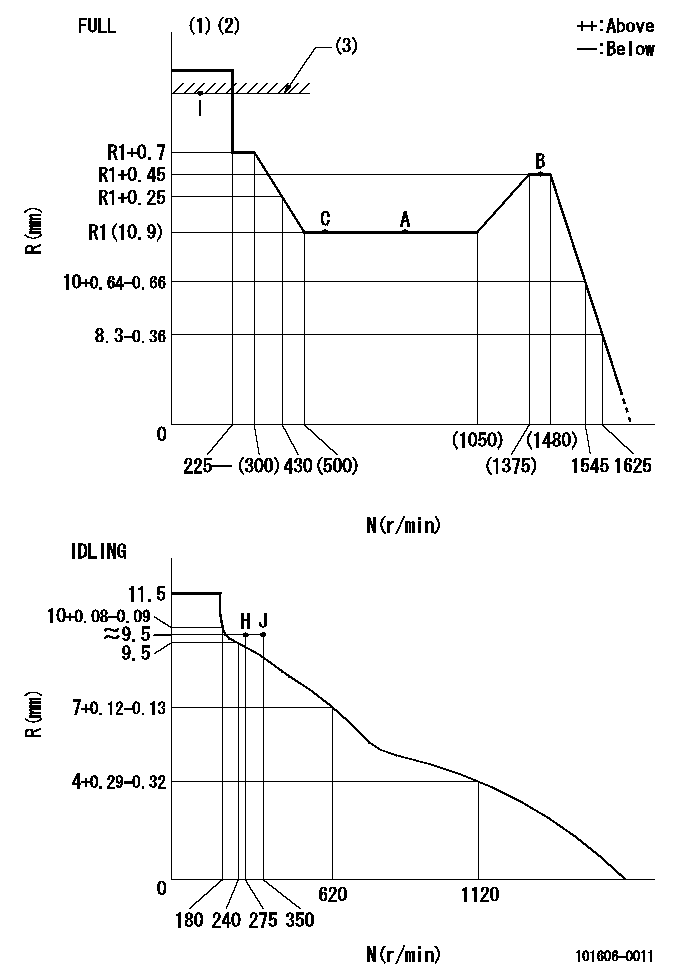

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

----------

T1=K77

----------

----------

T1=K77

----------

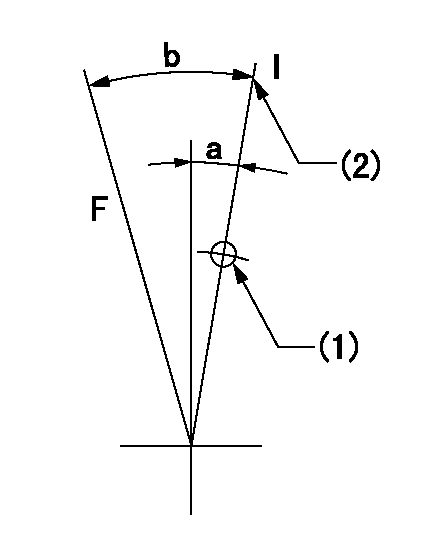

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt setting

----------

aa=35mm

----------

a=14deg+-5deg b=35deg+-3deg

----------

aa=35mm

----------

a=14deg+-5deg b=35deg+-3deg

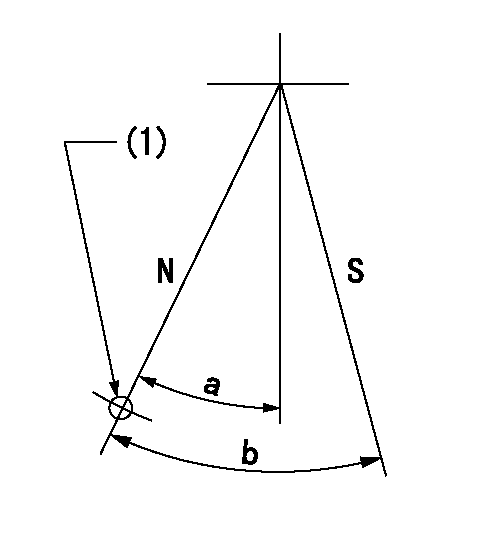

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the pin at R = aa

----------

aa=46.5mm

----------

a=34.5deg+-5deg b=40deg+-5deg

----------

aa=46.5mm

----------

a=34.5deg+-5deg b=40deg+-5deg

0000001501 AIR CYLINDER

1. (1) Set the speed lever to idle.

(2)Screw in air cylinder (A)

(3)Set the clearance from the speed lever (B) at approximately L.

----------

L=1mm

----------

----------

L=1mm

----------

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=14deg

----------

a=(160deg)

----------

aa=14deg

----------

a=(160deg)

Information:

Using water that meets the minimum acceptable water requirement may not prevent drop-out of these chemical compounds totally, but should minimize the rate to acceptable levels.To determine water characteristics, contact local water department, agricultural agent or an independent laboratory to perform the testing service. Two companies are listed below. However, there are others who are qualified to provide this service.L.O.C.C. Corp.

905 Bayshore Drive

Coos Bay, OR 97420

Ph. (503) 267-4904

NALCO Chemical Co.

Naperville Technical Center

One Nalco Center

Naperville, IL 60566

Attn: Sample Receiving

Ph. (312) 961-9500

Antifreeze

Caterpillar recommends that the coolant mix contain a minimum of 30% Caterpillar Antifreeze, or equivalent and acceptable water to maintain an adequate water pump cavitation temperature for efficient water pump performance.

Premix coolant solution to provide protection to the lowest expected outside (ambient) temperature. Pure undiluted antifreeze will freeze at- 10°F (-23°C).Only use a greater concentration (above 30%) of Caterpillar Antifreeze as needed for anticipated outside (ambient) temperatures. Do not exceed a coolant mixture of 60% antifreeze to water since a concentration above 60% antifreeze will reduce the engine's freeze protection and increase the possibility of deposit formation in the cooling system.Use Caterpillar Antifreeze or ASTM D4985-89 (GM Specification 6038-M) Antifreeze. Caterpillar Antifreeze is available through your Caterpillar dealer in quantities that follow. Most commercial antifreezes are formulated for gasoline engine applications and will, therefore, have high silicate content. Caterpillar Antifreeze is formulated with a low silicate content and the proper coolant additives for heavy duty diesel engines.ASTM D4985-89 (GM Specification 6038-M) is a low silicate antifreeze, but supplemental coolant additive must be added.The major advantages of Caterpillar Antifreeze are: * Significantly reduces water pump seal leakage problems caused by excessive concentration of chemical additives.* There is no need to add supplemental coolant additive on initial fill which must be done with current commercially available antifreezes.* High silicate antifreezes used with a supplemental coolant additive can cause a build-up of solids over a period of time which can cause plugging, loss of heat transfer, and water pump seal damage. Make proper antifreeze additions.Adding pure antifreeze as a makeup solution for cooling system top-up is an unacceptable practice. It increases the concentration of antifreeze in the cooling system which increases the concentration of dissolved solids and undissolved chemical inhibitors in the cooling system. Add antifreeze mixed with water to the same freeze protection as your cooling system.Use the chart below to assist in determining the concentration of Caterpillar Antifreeze to use.

5P0957 Coolant Tester (°F) or 5P3514 Coolant Tester (°C)Both are available at your Caterpillar dealer.Check the coolant solution frequently in cold weather for glycol concentration with the 5P0957 or 5P3514 Coolant Tester to ensure adequate protection. Both testers are identical except temperature scale. They give immediate, accurate readings and can be used for antifreeze/coolants that contain ethylene or propylene glycol.If propylene glycol based antifreeze is used, DO NOT allow concentration greater than a 50/50 antifreeze to water mixture. The measurement of freeze protection must be made with a refractive-type tester (Cat 5P0957 or 5P3514) rather than a hydrometer-type, which can be

905 Bayshore Drive

Coos Bay, OR 97420

Ph. (503) 267-4904

NALCO Chemical Co.

Naperville Technical Center

One Nalco Center

Naperville, IL 60566

Attn: Sample Receiving

Ph. (312) 961-9500

Antifreeze

Caterpillar recommends that the coolant mix contain a minimum of 30% Caterpillar Antifreeze, or equivalent and acceptable water to maintain an adequate water pump cavitation temperature for efficient water pump performance.

Premix coolant solution to provide protection to the lowest expected outside (ambient) temperature. Pure undiluted antifreeze will freeze at- 10°F (-23°C).Only use a greater concentration (above 30%) of Caterpillar Antifreeze as needed for anticipated outside (ambient) temperatures. Do not exceed a coolant mixture of 60% antifreeze to water since a concentration above 60% antifreeze will reduce the engine's freeze protection and increase the possibility of deposit formation in the cooling system.Use Caterpillar Antifreeze or ASTM D4985-89 (GM Specification 6038-M) Antifreeze. Caterpillar Antifreeze is available through your Caterpillar dealer in quantities that follow. Most commercial antifreezes are formulated for gasoline engine applications and will, therefore, have high silicate content. Caterpillar Antifreeze is formulated with a low silicate content and the proper coolant additives for heavy duty diesel engines.ASTM D4985-89 (GM Specification 6038-M) is a low silicate antifreeze, but supplemental coolant additive must be added.The major advantages of Caterpillar Antifreeze are: * Significantly reduces water pump seal leakage problems caused by excessive concentration of chemical additives.* There is no need to add supplemental coolant additive on initial fill which must be done with current commercially available antifreezes.* High silicate antifreezes used with a supplemental coolant additive can cause a build-up of solids over a period of time which can cause plugging, loss of heat transfer, and water pump seal damage. Make proper antifreeze additions.Adding pure antifreeze as a makeup solution for cooling system top-up is an unacceptable practice. It increases the concentration of antifreeze in the cooling system which increases the concentration of dissolved solids and undissolved chemical inhibitors in the cooling system. Add antifreeze mixed with water to the same freeze protection as your cooling system.Use the chart below to assist in determining the concentration of Caterpillar Antifreeze to use.

5P0957 Coolant Tester (°F) or 5P3514 Coolant Tester (°C)Both are available at your Caterpillar dealer.Check the coolant solution frequently in cold weather for glycol concentration with the 5P0957 or 5P3514 Coolant Tester to ensure adequate protection. Both testers are identical except temperature scale. They give immediate, accurate readings and can be used for antifreeze/coolants that contain ethylene or propylene glycol.If propylene glycol based antifreeze is used, DO NOT allow concentration greater than a 50/50 antifreeze to water mixture. The measurement of freeze protection must be made with a refractive-type tester (Cat 5P0957 or 5P3514) rather than a hydrometer-type, which can be