Information injection-pump assembly

BOSCH

9 400 611 514

9400611514

ZEXEL

101605-9531

1016059531

MITSUBISHI-HEAV

3436103070

3436103070

Rating:

Service parts 101605-9531 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

34361-11010

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 611 514

9400611514

ZEXEL

101605-9531

1016059531

MITSUBISHI-HEAV

3436103070

3436103070

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5720

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

6.9

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

39.2

38.2

40.2

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

6.6+-0.5

Pump speed

r/min

425

425

425

Average injection quantity

mm3/st.

12

10.7

13.3

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

60

65

Fixing the lever

*

Rack limit

*

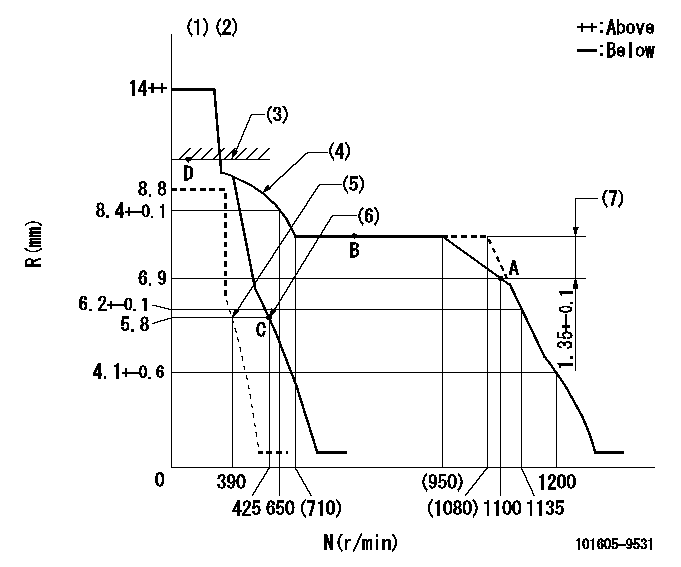

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)The torque control spring must does not have a set force.

(5)Set idle sub-spring

(6)Main spring setting

(7)Rack difference between N = N1 and N = N2

----------

K=15 N1=1100r/min N2=750r/min

----------

----------

K=15 N1=1100r/min N2=750r/min

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=(21deg)+-5deg b=(27deg)+-5deg

----------

----------

a=(21deg)+-5deg b=(27deg)+-5deg

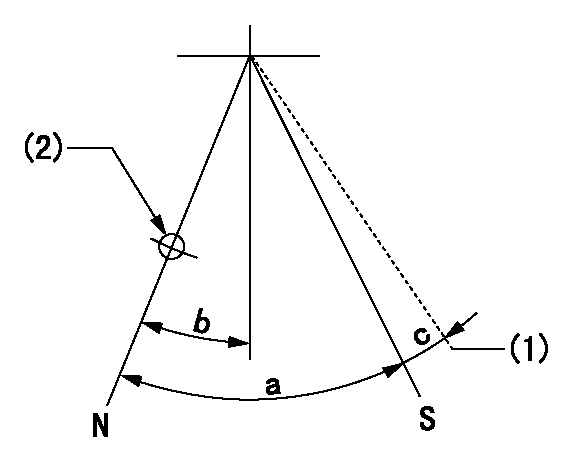

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Hold the boss against the stop side

(2)Use the hole at R = aa

----------

aa=60mm

----------

a=53deg+-5deg b=26.5deg+-5deg c=(9deg)

----------

aa=60mm

----------

a=53deg+-5deg b=26.5deg+-5deg c=(9deg)

Timing setting

(1)Pump vertical direction

(2)Position of camshaft's key groove at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(60deg)

----------

----------

a=(60deg)

Information:

Caterpillar Reference Material

Lubricants

Oil and Your Engine SEBD0640Scheduled Oil Sampling PEDP1129Branded Fluids Question & Answer Booklet PEDP7122Cat Fluids - Molybdenum Grease (MPGM) PEHP0002Cat Fluids - Lithium Grease (MPGL) PEHP0003Cat Fluids - Special Purpose Grease (SPG) PEHP0017How to Take a Good Oil Sample PEHP6001Caterpillar Fluids Selector Dial PEWP9733Fuels

Diesel Fuels and Your Engine SEBD0717Coolants

Know Your Cooling System SEBD0518Coolant and Your Engine SEBD0970Service Manuals

3408 & 3412 Service Manual (9XM & 9XF) SENR4655Engine Supervisory System Operation Manual SEBU6260Special Instructions

The following Special Instructions pertain to the operation, maintenance, diagnostic tooling and programming of the Electronic system. Some of these publications will be included in the tool kits, the others will be available thru your Caterpillar dealer.Storage Procedure for Caterpillar Products SEHS9031Miscellaneous

Index to Guidelines for Reusable Parts and Salvage Operations SEBF8029Guideline for Reusable Parts (Cleaning and Inspection of Air Filters) SEBF8062Tag - DO NOT OPERATE SEHS7332All of the above publications are available through your Caterpillar dealer.Additional Reference Material

ASTM Specs can normally be obtained from your local technological society, library or college or contacting:* American Society for Testing and Materials

1916 Race St.

Philadelphia, PA 19103

(215) 299-5400

Society of Automotive Engineers (SAE) Specs can be found in your SAE handbook or can be obtained from your local library, college or technological society, or contacting:* Society of Automotive Engineers, Inc.

SAE International

400 Commonwealth Drive

Warrendale, PA USA 15096-0001

(412) 776-4841

American Petroleum Institute (API) classification system and oil selection for API Publication No. 1509 can be obtained from your local library, college or technological society, or contact:* American Petroleum Institute

1220 L St.

Washington, DC 20005

(202) 682-8000

Engine Manufacturers Association (EMA) information for lube oil selection can be obtained from your local library, college or technological society, or contact:* Engine Manufacturers Association

Lubricating Oils Data Book

401 N. Michigan Ave. Ste. 2400

Chicago, IL 60611

(312) 644-6610 ext. 3626

Lubricants

Oil and Your Engine SEBD0640Scheduled Oil Sampling PEDP1129Branded Fluids Question & Answer Booklet PEDP7122Cat Fluids - Molybdenum Grease (MPGM) PEHP0002Cat Fluids - Lithium Grease (MPGL) PEHP0003Cat Fluids - Special Purpose Grease (SPG) PEHP0017How to Take a Good Oil Sample PEHP6001Caterpillar Fluids Selector Dial PEWP9733Fuels

Diesel Fuels and Your Engine SEBD0717Coolants

Know Your Cooling System SEBD0518Coolant and Your Engine SEBD0970Service Manuals

3408 & 3412 Service Manual (9XM & 9XF) SENR4655Engine Supervisory System Operation Manual SEBU6260Special Instructions

The following Special Instructions pertain to the operation, maintenance, diagnostic tooling and programming of the Electronic system. Some of these publications will be included in the tool kits, the others will be available thru your Caterpillar dealer.Storage Procedure for Caterpillar Products SEHS9031Miscellaneous

Index to Guidelines for Reusable Parts and Salvage Operations SEBF8029Guideline for Reusable Parts (Cleaning and Inspection of Air Filters) SEBF8062Tag - DO NOT OPERATE SEHS7332All of the above publications are available through your Caterpillar dealer.Additional Reference Material

ASTM Specs can normally be obtained from your local technological society, library or college or contacting:* American Society for Testing and Materials

1916 Race St.

Philadelphia, PA 19103

(215) 299-5400

Society of Automotive Engineers (SAE) Specs can be found in your SAE handbook or can be obtained from your local library, college or technological society, or contacting:* Society of Automotive Engineers, Inc.

SAE International

400 Commonwealth Drive

Warrendale, PA USA 15096-0001

(412) 776-4841

American Petroleum Institute (API) classification system and oil selection for API Publication No. 1509 can be obtained from your local library, college or technological society, or contact:* American Petroleum Institute

1220 L St.

Washington, DC 20005

(202) 682-8000

Engine Manufacturers Association (EMA) information for lube oil selection can be obtained from your local library, college or technological society, or contact:* Engine Manufacturers Association

Lubricating Oils Data Book

401 N. Michigan Ave. Ste. 2400

Chicago, IL 60611

(312) 644-6610 ext. 3626