Information injection-pump assembly

BOSCH

9 400 610 703

9400610703

ZEXEL

101605-9460

1016059460

NISSAN-DIESEL

16712Z5511

16712z5511

Rating:

Service parts 101605-9460 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

16600-Z5607

12.

Open Pre:MPa(Kqf/cm2)

19.6{200}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 610 703

9400610703

ZEXEL

101605-9460

1016059460

NISSAN-DIESEL

16712Z5511

16712z5511

Zexel num

Bosch num

Firm num

Name

101605-9460

9 400 610 703

16712Z5511 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

FE6T45 K 14BE INJECTION PUMP ASSY PE6A PE

FE6T45 K 14BE INJECTION PUMP ASSY PE6A PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-1520

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.3

3.25

3.35

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

8.5

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

69.5

67.5

71.5

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the rack

*

Boost pressure

kPa

42

42

Boost pressure

mmHg

315

315

Injection quantity adjustment_02

Adjusting point

C

Rack position

R1(8.6)

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

53

52

54

Max. variation between cylinders

%

0

-5

5

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_03

Adjusting point

D

Rack position

6.8+-0.5

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

8

6.2

9.8

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

400

400

400

Rack position

R1(8.6)

Boost pressure

kPa

4.7

3.4

6

Boost pressure

mmHg

35

25

45

Boost compensator adjustment_02

Pump speed

r/min

400

400

400

Rack position

(9.5)

Boost pressure

kPa

28.7

28.7

28.7

Boost pressure

mmHg

215

215

215

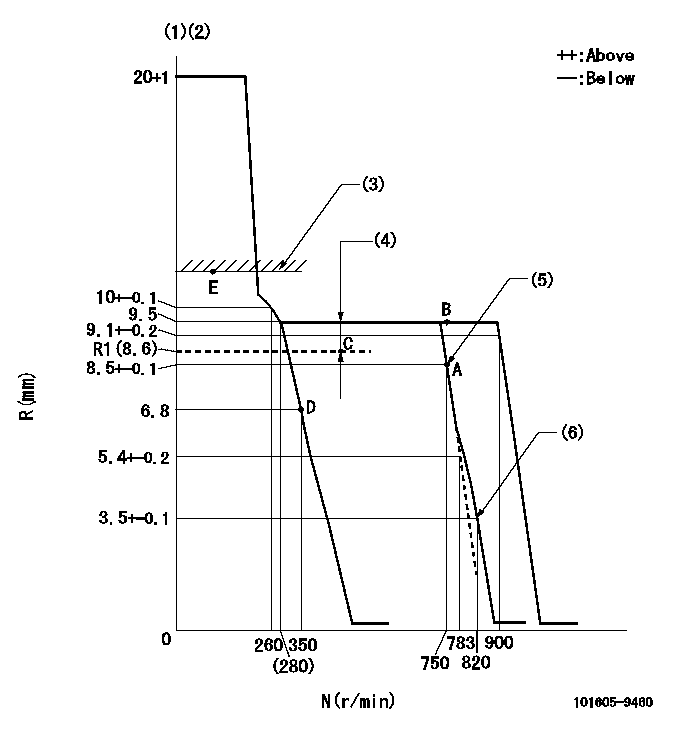

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Boost compensator excessive fuel lever at operation (at 0 boost pressure): L1

(4)Boost compensator stroke: BCL

(5)Main spring setting

(6)Set idle sub-spring

----------

K=13 L1=10.5+-0.1mm BCL=(0.9)mm

----------

----------

K=13 L1=10.5+-0.1mm BCL=(0.9)mm

----------

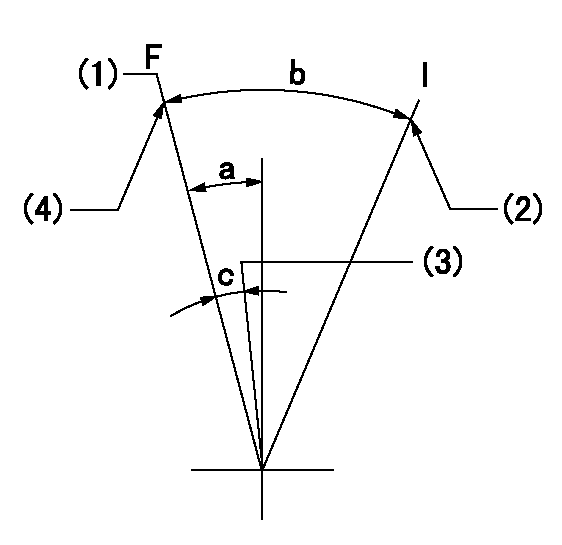

Speed control lever angle

F:Full speed

I:Idle

(1)Set the pump speed at aa

(2)Stopper bolt setting

(3)When pump speed set at bb

(4)Stopper bolt setting

----------

aa=900r/min bb=750r/min

----------

a=6deg+-5deg b=20deg+-5deg c=5deg+-5deg

----------

aa=900r/min bb=750r/min

----------

a=6deg+-5deg b=20deg+-5deg c=5deg+-5deg

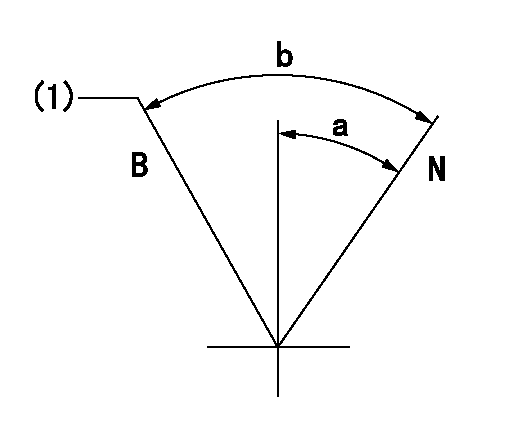

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=26.5deg+-5deg b=53deg+-5deg

----------

----------

a=26.5deg+-5deg b=53deg+-5deg

0000001101

N:Normal

B:When boosted

(1)Rack position = aa (at boost pressure = bb)

----------

aa=10.5+-0.1mm bb=0kPa(0mmHg)

----------

a=(15deg) b=(25deg)

----------

aa=10.5+-0.1mm bb=0kPa(0mmHg)

----------

a=(15deg) b=(25deg)

Timing setting

(1)Pump vertical direction

(2)Position of coupling's threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(60deg)

----------

----------

a=(60deg)

Information:

Stopping the engine immediately after it has been working under load can result in overheating and accelerated wear of the engine components. Excessive temperatures in the turbocharger centerhousing will cause oil coking problems.

Prior to stopping an engine that is being operated at low loads, run the engine at low speed for 30 seconds before stopping. If the engine has been operating at high load, then it should be run at low speed for three to five minutes to reduce and stabilize internal engine coolant and oil temperatures before stopping. Avoiding hot engine shutdowns will maximize turbocharger shaft and bearing life. Make sure the Engine Stopping procedure is understood.Follow the engine stopping procedure outlined below to allow the engine to cool. Make sure the Engine Stopping procedure is understood.The engine may be shutdown in several ways. To manually stop the engine, refer to the following information and instructions. The engine is equipped with an Emergency Stop Push Button (ESPB) and an Engine Control Switch (ECS), which is OEM provided.Emergency Stop Procedure

Emergency stop controls are for EMERGENCY use ONLY. DO NOT use Emergency Stop Pushbutton (ESPB) for normal stopping procedure. Do NOT start the engine until the problem necessitating the emergency stop has been located and corrected.

The engine may be installed with an Emergency Stop Pushbutton. The Emergency Stop Pushbutton may be located on the front of the control panel. The Emergency Stop Pushbutton will cause immediate shutoff of fuel and/or air. Emergency shutoff controls (including any auxiliary Emergency Stop inputs) should only be used when an emergency exists, and not used to routinely stop the engine.* Emergency stops may be made through the Emergency Stop Pushbutton (ESPB). If the need for emergency engine shutdown occurs, Push the EMERGENCY STOP Pushbutton located on the control panel. This will activate the air and/or fuel shutoffs.* Reset the EMERGENCY STOP Pushbutton (pull out and rotate the button in the direction indicated on the button). Some EMERGENCY STOP Pushbuttons can be pulled out to reset, not requiring any rotation.Manual Fuel Shutoff

A manual shutdown shaft is provided to override the governor control of the engine. This shutdown will only move the fuel control linkage to the fuel OFF position to starve the engine of fuel. The engine will coast to a stop. Be sure to secure any external system components that have been operating to support the engine operation.Manual Stop Procedure

Follow the engine stopping procedure outlined below, to allow the engine to cool. Make sure the Engine Stopping procedure is clearly understood.1. Reduce engine speed to low idle.2. Disengage driven equipment or remove load from engine.3. Move governor control to increase engine speed to no more than half engine speed for two minutes.4. Reduce engine speed to low idle for five minutes to cool the engine and prevent oil coking problems in the turbocharger centerhousing.5. Depending on your control, stop the engine by turning the start switch to the OFF position or refer below to the governor controls that your engine may be equipped

Have questions with 101605-9460?

Group cross 101605-9460 ZEXEL

Mitsubishi-Heav

Dpico

Mitsubishi-Heav

Nissan-Diesel

Nissan-Diesel

101605-9460

9 400 610 703

16712Z5511

INJECTION-PUMP ASSEMBLY

FE6T45

FE6T45