Information injection-pump assembly

ZEXEL

101605-9340

1016059340

NISSAN-DIESEL

1679095065

1679095065

Rating:

Service parts 101605-9340 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

16600-95011

12.

Open Pre:MPa(Kqf/cm2)

19.6{200}

15.

NOZZLE SET

Include in #1:

101605-9340

as INJECTION-PUMP ASSEMBLY

Include in #2:

104746-1460

as _

Cross reference number

ZEXEL

101605-9340

1016059340

NISSAN-DIESEL

1679095065

1679095065

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-1520

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

2.75

2.7

2.8

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.6

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

101.5

100

103

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Boost pressure

kPa

65.3

65.3

Boost pressure

mmHg

490

490

Injection quantity adjustment_02

Adjusting point

C

Rack position

R1(9.9)

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

82.5

80.5

84.5

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_03

Adjusting point

D

Rack position

6.4+-0.5

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

10.5

9

12

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

600

600

600

Rack position

R1(9.9)

Boost pressure

kPa

20

17.3

22.7

Boost pressure

mmHg

150

130

170

Boost compensator adjustment_02

Pump speed

r/min

600

600

600

Rack position

10.6

Boost pressure

kPa

52

45.3

58.7

Boost pressure

mmHg

390

340

440

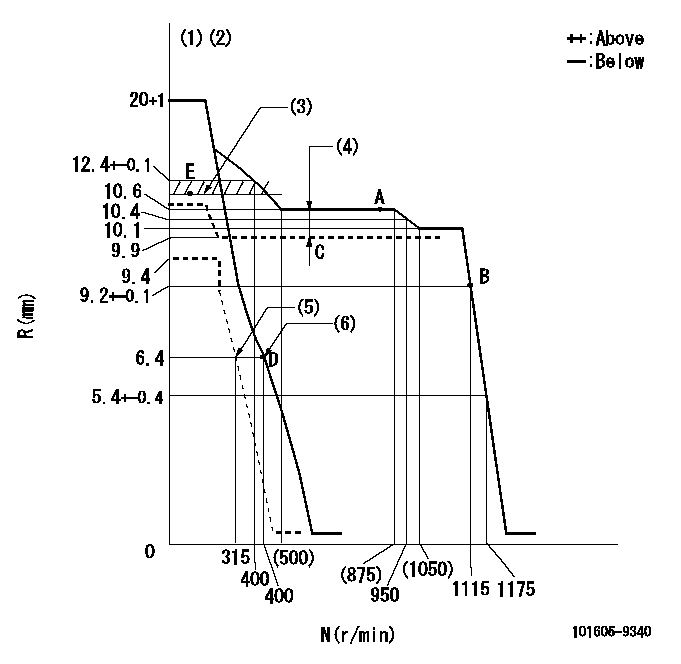

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Boost compensator excessive fuel lever at operation: L1 (at 0 boost pressure)

(4)Boost compensator stroke: BCL

(5)Set idle sub-spring

(6)Main spring setting

----------

K=10 L1=11.5+-0.2mm BCL=(0.7)+-0.1mm

----------

----------

K=10 L1=11.5+-0.2mm BCL=(0.7)+-0.1mm

----------

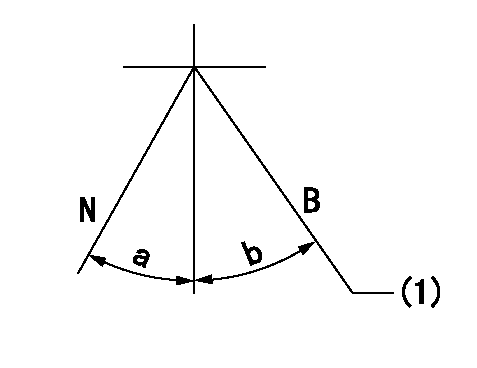

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=3deg+-5deg b=18deg+-5deg

----------

----------

a=3deg+-5deg b=18deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=26.5deg+-5deg b=53deg+-5deg

----------

----------

a=26.5deg+-5deg b=53deg+-5deg

0000001101

N:Normal

B:When boosted

(1)Rack position = aa at boost pressure 0.

----------

aa=11.5+-0.2mm

----------

a=(15deg) b=(8deg)

----------

aa=11.5+-0.2mm

----------

a=(15deg) b=(8deg)

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=16deg

----------

a=(30deg)

----------

aa=16deg

----------

a=(30deg)

Information:

Fuel Recommendations

Caterpillar Diesel Engines are capable of burning a wide range of distillate fuels. The use of clean, stable blends of distillate fuel which meet the following requirements will provide quality engine service life. The fuels recommended for use in Caterpillar engines are normally No. 2-D diesel fuel and No. 2 fuel oil, although No. 1 grades are acceptable. The following fuel specifications are some of the worldwide fuels which also meet the requirements. The following fuel characteristics should be considered when procuring fuel for use in Caterpillar diesel engines.Cetane Number

The minimum cetane number required for average starting conditions for the direct injection engine is 40. A higher cetane value may be required for high altitude operation or cold weather starting.Filterability

Clean fuels should have no more than 0.1% of sediment and water. Storage of fuel for extended periods of time can cause fuel oxidation with solids forming, causing filtering problems.Pour Point

The pour point of the fuel should be at least 6°C (10°F) below the lowest ambient temperature at which the engines must start and operate. The lower pour point of No. 1 or No. 1-D fuel may be necessary in extremely cold weather.Cloud Point

The cloud point should be below the lowest ambient temperature at which the engines must start and operate to prevent the fuel filter elements from plugging with wax crystals. Refer to topic, Fuel Problems in Cold Weather Operation, for additional information.Sulfur

Fuels containing 0.5% or less sulfur may be used with normal crankcase oil drain intervals using API CD or CE performance oils. With sulfur above the 0.5% level, use API CD or CE oils with an ASTM D-2896 Total Base Number (TBN) of 20 times the fuel sulfur for normal oil drain intervals. Regular oil analysis (S*O*S) will provide information to monitor oil properties and engine wear metals to maintain successful engine protection and establish oil drain intervals.Viscosity

The viscosity of any fluid is a measure of resistance to flow. Fuel viscosity is important because it provides lubrication for fuel system components and also its effects on fuel atomization. The viscosity limits have been provided to meet both of these effects.Additives

Fuel additives are generally not recommended nor needed for the specified fuels listed. Cetane improvers can be used as necessary for the direct injection engine requirements. Biocides may be needed to eliminate microorganism growth in storage tanks. In cold conditions, treatment for entrained water may also be necessary.Consult your fuel supplier about the use of additives to prevent incompatibility among additives already in the fuel and the additives to be used. Other fuel types may be burned in the engine when economics or fuel availability dictate. Consult your Caterpillar dealer for more information and advice on any specific fuel.Fuel Sulfur Content

The percentage of sulfur in the fuel will affect the engine oil recommendations. Fuel sulfur is chemically changed during combustion to form both sulfurous and sulfuric acid. These acids chemically attack metal surfaces and cause corrosive wear.Certain additives used in lubricating oils contain alkaline compounds that

Caterpillar Diesel Engines are capable of burning a wide range of distillate fuels. The use of clean, stable blends of distillate fuel which meet the following requirements will provide quality engine service life. The fuels recommended for use in Caterpillar engines are normally No. 2-D diesel fuel and No. 2 fuel oil, although No. 1 grades are acceptable. The following fuel specifications are some of the worldwide fuels which also meet the requirements. The following fuel characteristics should be considered when procuring fuel for use in Caterpillar diesel engines.Cetane Number

The minimum cetane number required for average starting conditions for the direct injection engine is 40. A higher cetane value may be required for high altitude operation or cold weather starting.Filterability

Clean fuels should have no more than 0.1% of sediment and water. Storage of fuel for extended periods of time can cause fuel oxidation with solids forming, causing filtering problems.Pour Point

The pour point of the fuel should be at least 6°C (10°F) below the lowest ambient temperature at which the engines must start and operate. The lower pour point of No. 1 or No. 1-D fuel may be necessary in extremely cold weather.Cloud Point

The cloud point should be below the lowest ambient temperature at which the engines must start and operate to prevent the fuel filter elements from plugging with wax crystals. Refer to topic, Fuel Problems in Cold Weather Operation, for additional information.Sulfur

Fuels containing 0.5% or less sulfur may be used with normal crankcase oil drain intervals using API CD or CE performance oils. With sulfur above the 0.5% level, use API CD or CE oils with an ASTM D-2896 Total Base Number (TBN) of 20 times the fuel sulfur for normal oil drain intervals. Regular oil analysis (S*O*S) will provide information to monitor oil properties and engine wear metals to maintain successful engine protection and establish oil drain intervals.Viscosity

The viscosity of any fluid is a measure of resistance to flow. Fuel viscosity is important because it provides lubrication for fuel system components and also its effects on fuel atomization. The viscosity limits have been provided to meet both of these effects.Additives

Fuel additives are generally not recommended nor needed for the specified fuels listed. Cetane improvers can be used as necessary for the direct injection engine requirements. Biocides may be needed to eliminate microorganism growth in storage tanks. In cold conditions, treatment for entrained water may also be necessary.Consult your fuel supplier about the use of additives to prevent incompatibility among additives already in the fuel and the additives to be used. Other fuel types may be burned in the engine when economics or fuel availability dictate. Consult your Caterpillar dealer for more information and advice on any specific fuel.Fuel Sulfur Content

The percentage of sulfur in the fuel will affect the engine oil recommendations. Fuel sulfur is chemically changed during combustion to form both sulfurous and sulfuric acid. These acids chemically attack metal surfaces and cause corrosive wear.Certain additives used in lubricating oils contain alkaline compounds that