Information injection-pump assembly

ZEXEL

101605-9171

1016059171

Rating:

Service parts 101605-9171 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

10.

NOZZLE AND HOLDER ASSY

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

13.

NOZZLE-HOLDER

14.

NOZZLE

15.

NOZZLE SET

Include in #1:

101605-9171

as INJECTION-PUMP ASSEMBLY

Include in #2:

104746-1390

as _

Cross reference number

ZEXEL

101605-9171

1016059171

Zexel num

Bosch num

Firm num

Name

101605-9171

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

6-3-5-1-

4-2

Pre-stroke

mm

3.2

3.15

3.25

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 6-3 deg. 60 59.5 60.5

Cal 6-3 deg. 60 59.5 60.5

Difference between angles 2

Cal 6-5 deg. 120 119.5 120.5

Cal 6-5 deg. 120 119.5 120.5

Difference between angles 3

Cal 6-1 deg. 180 179.5 180.5

Cal 6-1 deg. 180 179.5 180.5

Difference between angles 4

Cal 6-4 deg. 240 239.5 240.5

Cal 6-4 deg. 240 239.5 240.5

Difference between angles 5

Cal 6-2 deg. 300 299.5 300.5

Cal 6-2 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.1

Pump speed

r/min

1000

1000

1000

Each cylinder's injection qty

mm3/st.

144.5

141.6

147.4

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

6.2+-0.5

Pump speed

r/min

500

500

500

Each cylinder's injection qty

mm3/st.

20.5

17.9

23.1

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

185

185

205

Fixing the lever

*

Rack limit

*

Test data Ex:

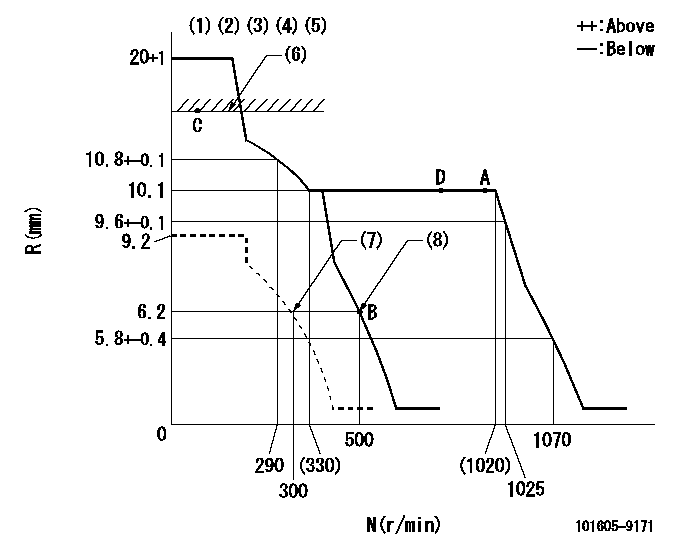

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Solenoid operation confirmation

(4)1. At idle speed (N = aa), confirm that the solenoid moves through its full stroke (stop lever angle D2).

(5)2. After confirming 1, confirm that it is pulled back to R = cc at N = bb.

(6)RACK LIMIT

(7)Set idle sub-spring

(8)Main spring setting

----------

K=11 aa=500r/min D2=(50)deg bb=100r/min cc=5mm

----------

----------

K=11 aa=500r/min D2=(50)deg bb=100r/min cc=5mm

----------

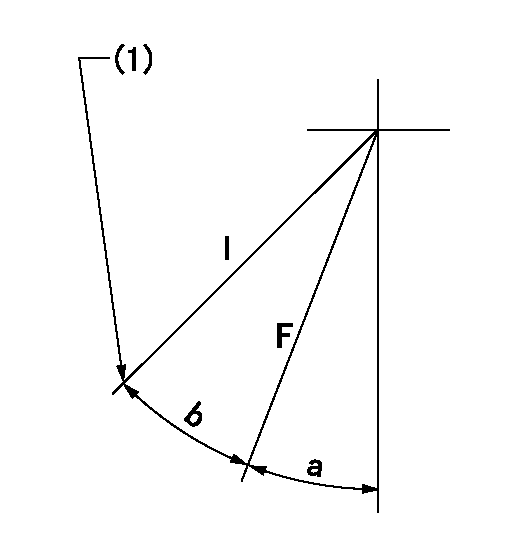

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=(13deg)+-5deg b=(25deg)+-5deg

----------

----------

a=(13deg)+-5deg b=(25deg)+-5deg

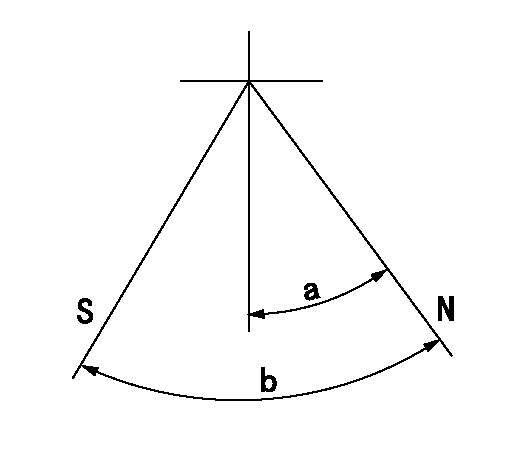

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=(26deg) b=(50deg)

----------

----------

a=(26deg) b=(50deg)

Timing setting

(1)Pump vertical direction

(2)Camshaft's key groove position at No. 6 cylinder's beginning of injection.

(3)-

(4)-

----------

----------

a=(130deg)

----------

----------

a=(130deg)

Information:

Vessels using diesel engines for main propulsion are required by the various Marine Shipping Societies to carry a supply of replacement parts on-board. Although individual requirements may differ, the following list takes into consideration the requirements of all Marine Shipping Societies and several items recommended by Caterpillar. To customize this list for your particular engine arrangement and application, contact your authorized dealer and provide the following information.1. Engine Serial Number2. Engine Arrangement Number3. Rated Horsepower4. Electrical System (12V or 24V)5. Alternator (1 or 2 belts) (from Parts Manual)6. Sea (Raw) Water Pump Part No. (from Parts Manual)7. Type of Air Filter8. Water Lines Group (from Parts Manual)9. Spin on Conditioner (Y/N)10. PCV Group No. (from Parts Manual)11. Type Water Separator12. Marine Gear ModelSuggested Replacement Parts (to be carried on board)

Category I (Intercoastal)

Parts needed for servicing minor problems at remote ports or secondary repairs offshore.* Alternator Belt* Fuel Injection Nozzles* Four Oil Filters* Four Fuel Filters* Four Zinc Rods* Four Temperature Regulators* Four Air Cleaner Elements* S O S. Bottle Group* Liquid Gasket Material* Engine Oil* Antifreeze* Coolant Corrosion Inhibitor* Coolant ConditionerCategory II (Ocean-going)

Parts needed for extended travel from a servicing port or for maintaining an extensive set of spare parts on board.Ocean-going vessels should carry all replacement parts listed in Category I as well as the items listed below. Cylinder Head Parts* One complete service head assembly.* Five cylinder head bolts and washers.* Four intake valve inserts.* Six exhaust valve inserts.* One exhaust manifold stud and nut. Valve Parts* Four intake valves.* Six exhaust valves.* Ten valve guides.* Ten rotocoil assemblies.* Ten valve springs.* Twenty-four locks. Piston Parts-Power* One piston group.* One connecting rod assembly.* One connecting rod bearing.* One piston pin.* Two piston pin retainers.* One complete set of rings for one piston.* One main bearing.* Two thrust plates.* Two main bearing cap bolts and washers.* One cylinder liner.* Three cylinder liner seals.* One cylinder liner filler band.* One oil pan gasket. Fuel System Parts* One fuel injection pump group and O-ring seal.* One set (each) of the fuel injection lines.* Four fuel nozzle assemblies, fuel bodies and nuts.* One seal and gasket for fuel nozzle adapter.* One seal, lock and adapter assembly to connect fuel lines through cylinder head.* One fuel transfer pump. Camshaft Drive Parts* One water pump idler and balance weight gear assembly.* One shaft and thrust washer for idler and balance weight gear.* One crankshaft gear.* One camshaft gear and key. Air System Parts* One complete turbocharger group.* Four turbocharger mounting studs and locknuts.* One air cleaner element.* One aftercooler core.* One each of the bypass valves for oil cooler and oil filter (valve body).* One bolt for oil pan.* One engine oil cooler core.* One marine gear oil cooler core.* One temperature regulator.* One vee belt set (if so equipped).* One jacket water pump.* One sea (raw) water pump.* One complete engine gasket kit.* One flywheel to crankshaft bolt.* One bolt for valve cover.* One repair kit for piston and rings of

Category I (Intercoastal)

Parts needed for servicing minor problems at remote ports or secondary repairs offshore.* Alternator Belt* Fuel Injection Nozzles* Four Oil Filters* Four Fuel Filters* Four Zinc Rods* Four Temperature Regulators* Four Air Cleaner Elements* S O S. Bottle Group* Liquid Gasket Material* Engine Oil* Antifreeze* Coolant Corrosion Inhibitor* Coolant ConditionerCategory II (Ocean-going)

Parts needed for extended travel from a servicing port or for maintaining an extensive set of spare parts on board.Ocean-going vessels should carry all replacement parts listed in Category I as well as the items listed below. Cylinder Head Parts* One complete service head assembly.* Five cylinder head bolts and washers.* Four intake valve inserts.* Six exhaust valve inserts.* One exhaust manifold stud and nut. Valve Parts* Four intake valves.* Six exhaust valves.* Ten valve guides.* Ten rotocoil assemblies.* Ten valve springs.* Twenty-four locks. Piston Parts-Power* One piston group.* One connecting rod assembly.* One connecting rod bearing.* One piston pin.* Two piston pin retainers.* One complete set of rings for one piston.* One main bearing.* Two thrust plates.* Two main bearing cap bolts and washers.* One cylinder liner.* Three cylinder liner seals.* One cylinder liner filler band.* One oil pan gasket. Fuel System Parts* One fuel injection pump group and O-ring seal.* One set (each) of the fuel injection lines.* Four fuel nozzle assemblies, fuel bodies and nuts.* One seal and gasket for fuel nozzle adapter.* One seal, lock and adapter assembly to connect fuel lines through cylinder head.* One fuel transfer pump. Camshaft Drive Parts* One water pump idler and balance weight gear assembly.* One shaft and thrust washer for idler and balance weight gear.* One crankshaft gear.* One camshaft gear and key. Air System Parts* One complete turbocharger group.* Four turbocharger mounting studs and locknuts.* One air cleaner element.* One aftercooler core.* One each of the bypass valves for oil cooler and oil filter (valve body).* One bolt for oil pan.* One engine oil cooler core.* One marine gear oil cooler core.* One temperature regulator.* One vee belt set (if so equipped).* One jacket water pump.* One sea (raw) water pump.* One complete engine gasket kit.* One flywheel to crankshaft bolt.* One bolt for valve cover.* One repair kit for piston and rings of

Have questions with 101605-9171?

Group cross 101605-9171 ZEXEL

Daewoo

Yanmar

Dpico

Daewoo

Yanmar

101605-9171

INJECTION-PUMP ASSEMBLY