Information injection-pump assembly

BOSCH

9 400 610 692

9400610692

ZEXEL

101605-9162

1016059162

YANMAR

12760551010

12760551010

Rating:

Service parts 101605-9162 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

10.

NOZZLE AND HOLDER ASSY

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

13.

NOZZLE-HOLDER

14.

NOZZLE

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 610 692

9400610692

ZEXEL

101605-9162

1016059162

YANMAR

12760551010

12760551010

Zexel num

Bosch num

Firm num

Name

101605-9162

9 400 610 692

12760551010 YANMAR

INJECTION-PUMP ASSEMBLY

6CXL-DT K 14BF INJECTION PUMP ASSY PE6AD PE

6CXL-DT K 14BF INJECTION PUMP ASSY PE6AD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

6-3-5-1-

4-2

Pre-stroke

mm

3.2

3.15

3.25

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 6-3 deg. 60 59.5 60.5

Cal 6-3 deg. 60 59.5 60.5

Difference between angles 2

Cal 6-5 deg. 120 119.5 120.5

Cal 6-5 deg. 120 119.5 120.5

Difference between angles 3

Cal 6-1 deg. 180 179.5 180.5

Cal 6-1 deg. 180 179.5 180.5

Difference between angles 4

Cal 6-4 deg. 240 239.5 240.5

Cal 6-4 deg. 240 239.5 240.5

Difference between angles 5

Cal 6-2 deg. 300 299.5 300.5

Cal 6-2 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

11

Pump speed

r/min

910

910

910

Each cylinder's injection qty

mm3/st.

175

171.5

178.5

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

6.4+-0.5

Pump speed

r/min

400

400

400

Each cylinder's injection qty

mm3/st.

22.5

19.7

25.3

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

215

215

235

Fixing the lever

*

Rack limit

*

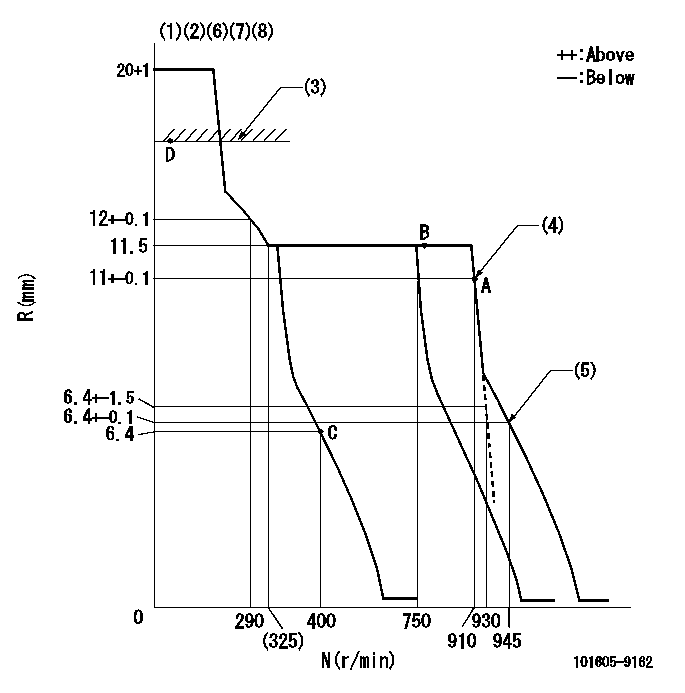

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Notch fixed: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Main spring setting

(5)Set idle sub-spring

(6)Solenoid operation confirmation

(7)1. At idle speed (N = aa), confirm that the solenoid moves through its full stroke (stop lever angle D2).

(8)2. After confirming 1, confirm that it is pulled back to R = cc at N = bb.

----------

K=10 aa=400r/min D2=(50)deg bb=100r/min cc=5mm

----------

----------

K=10 aa=400r/min D2=(50)deg bb=100r/min cc=5mm

----------

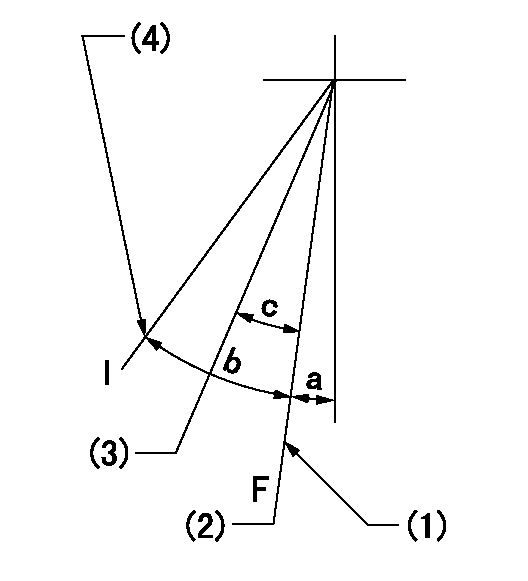

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

(2)Set the pump speed at aa

(3)When pump speed set at bb

(4)Stopper bolt setting

----------

aa=910r/min bb=750r/min

----------

a=(19deg)+-5deg b=(24deg)+-5deg c=(7deg)+-5deg

----------

aa=910r/min bb=750r/min

----------

a=(19deg)+-5deg b=(24deg)+-5deg c=(7deg)+-5deg

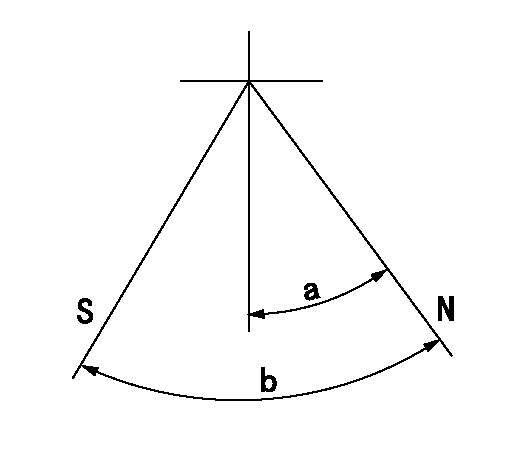

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=(19deg) b=(40deg)

----------

----------

a=(19deg) b=(40deg)

Timing setting

(1)Pump vertical direction

(2)Camshaft's key groove position at No. 6 cylinder's beginning of injection.

(3)-

(4)-

----------

----------

a=(130deg)

----------

----------

a=(130deg)

Information:

To Remove Injection Nozzles

Special tooling is required. See the Service Manual for this engine or your Caterpillar dealer.Turbocharger, Jacket Water Pump and Raw Water Pump

Operation of the engine until the turbocharger fails, can cause severe damage to the turbocharger's compressor wheel and/or the engine. For example, damage to the turbocharger compressor wheel could cause parts from the compressor wheel to enter the engine cylinder and cause additional damage to the piston, valve and cylinder head.A failed water pump might cause severe engine overheating problems that could result in cracks in the cylinder head, a piston seizure or other potential damage to the engine.Inspect/Rebuild or Exchange Turbocharger

Turbocharger bearing failures can cause large quantities of oil to enter the air intake and exhaust systems. Loss of engine lubricant can result in serious engine damage.Minor leakage of a turbocharger housing under extended low idle operation will not cause problems as long as no turbocharger bearing failure occurred.When a turbocharger bearing failure is accompanied by a significant engine performance loss (exhaust smoke or engine speed up at no load), DO NOT continue engine operation until the turbocharger is repaired or replaced.

1. Remove the exhaust outlet piping and inlet piping from the turbocharger. Visually check for oil leaks.2. Turn the turbine and compressor wheel by hand.3. The assembly should turn freely.4. Inspect the turbine wheel and compressor wheel for contact with the turbocharger housing.5. There should NOT be any visible signs of contact between the turbine or compressor wheel and the turbocharger housing.Check the compressor wheel for cleanliness. If only the blade side of the wheel is dirty, dirt and/or moisture is passing through the air filtering system.If oil is found only on the back side of the wheel, it indicates a turbo oil seal leak. The leak may be the result of extended engine operation at low idle or an intake air line restriction (plugged filters).Maintain the compressor wheel/turbo housing by cleaning with standard shop solvents and a soft bristle brush.6. Check the end play and bearing clearance on the turbine wheel and shaft with a dial indicator. Attach the indicator and position the pointer on the end of turbocharger shaft. Push and pull on the other end of the shaft observing the dial indicator for total reading. End play should read between 0.076 to 0.203 mm (.003 to .008 inch). If indicator reading exceeds this tolerance, the turbocharger should be rebuilt or replaced. If indicator reading is less than 0.076 mm (.003 inch), it may be an indication of carbon build-up on the turbine wheel. The turbocharger should be disassembled, cleaned and inspected.If the measurements are not within specifications, the turbocharger must be repaired or replaced.7. When installing or replacing V-band clamps, position the gap (tightening screw) down if possible so any accumulation of moisture will drain away.Turbocharger components require precision clearances and balancing due to operation at high rotational (torsional) speeds. Severe Service Applications can accelerate component wear and may suggest the need to Inspect/Repair/Replace the cartridge at reduced intervals

Special tooling is required. See the Service Manual for this engine or your Caterpillar dealer.Turbocharger, Jacket Water Pump and Raw Water Pump

Operation of the engine until the turbocharger fails, can cause severe damage to the turbocharger's compressor wheel and/or the engine. For example, damage to the turbocharger compressor wheel could cause parts from the compressor wheel to enter the engine cylinder and cause additional damage to the piston, valve and cylinder head.A failed water pump might cause severe engine overheating problems that could result in cracks in the cylinder head, a piston seizure or other potential damage to the engine.Inspect/Rebuild or Exchange Turbocharger

Turbocharger bearing failures can cause large quantities of oil to enter the air intake and exhaust systems. Loss of engine lubricant can result in serious engine damage.Minor leakage of a turbocharger housing under extended low idle operation will not cause problems as long as no turbocharger bearing failure occurred.When a turbocharger bearing failure is accompanied by a significant engine performance loss (exhaust smoke or engine speed up at no load), DO NOT continue engine operation until the turbocharger is repaired or replaced.

1. Remove the exhaust outlet piping and inlet piping from the turbocharger. Visually check for oil leaks.2. Turn the turbine and compressor wheel by hand.3. The assembly should turn freely.4. Inspect the turbine wheel and compressor wheel for contact with the turbocharger housing.5. There should NOT be any visible signs of contact between the turbine or compressor wheel and the turbocharger housing.Check the compressor wheel for cleanliness. If only the blade side of the wheel is dirty, dirt and/or moisture is passing through the air filtering system.If oil is found only on the back side of the wheel, it indicates a turbo oil seal leak. The leak may be the result of extended engine operation at low idle or an intake air line restriction (plugged filters).Maintain the compressor wheel/turbo housing by cleaning with standard shop solvents and a soft bristle brush.6. Check the end play and bearing clearance on the turbine wheel and shaft with a dial indicator. Attach the indicator and position the pointer on the end of turbocharger shaft. Push and pull on the other end of the shaft observing the dial indicator for total reading. End play should read between 0.076 to 0.203 mm (.003 to .008 inch). If indicator reading exceeds this tolerance, the turbocharger should be rebuilt or replaced. If indicator reading is less than 0.076 mm (.003 inch), it may be an indication of carbon build-up on the turbine wheel. The turbocharger should be disassembled, cleaned and inspected.If the measurements are not within specifications, the turbocharger must be repaired or replaced.7. When installing or replacing V-band clamps, position the gap (tightening screw) down if possible so any accumulation of moisture will drain away.Turbocharger components require precision clearances and balancing due to operation at high rotational (torsional) speeds. Severe Service Applications can accelerate component wear and may suggest the need to Inspect/Repair/Replace the cartridge at reduced intervals

Have questions with 101605-9162?

Group cross 101605-9162 ZEXEL

Daewoo

Yanmar

Dpico

Daewoo

Yanmar

101605-9162

9 400 610 692

12760551010

INJECTION-PUMP ASSEMBLY

6CXL-DT

6CXL-DT