Information injection-pump assembly

ZEXEL

101605-9160

1016059160

Rating:

Service parts 101605-9160 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

10.

NOZZLE AND HOLDER ASSY

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

13.

NOZZLE-HOLDER

14.

NOZZLE

15.

NOZZLE SET

Cross reference number

ZEXEL

101605-9160

1016059160

Zexel num

Bosch num

Firm num

Name

101605-9160

INJECTION-PUMP ASSEMBLY

14BF PE6AD PE

14BF PE6AD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

6-3-5-1-

4-2

Pre-stroke

mm

3.2

3.15

3.25

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 6-3 deg. 60 59.5 60.5

Cal 6-3 deg. 60 59.5 60.5

Difference between angles 2

Cal 6-5 deg. 120 119.5 120.5

Cal 6-5 deg. 120 119.5 120.5

Difference between angles 3

Cal 6-1 deg. 180 179.5 180.5

Cal 6-1 deg. 180 179.5 180.5

Difference between angles 4

Cal 6-4 deg. 240 239.5 240.5

Cal 6-4 deg. 240 239.5 240.5

Difference between angles 5

Cal 6-2 deg. 300 299.5 300.5

Cal 6-2 deg. 300 299.5 300.5

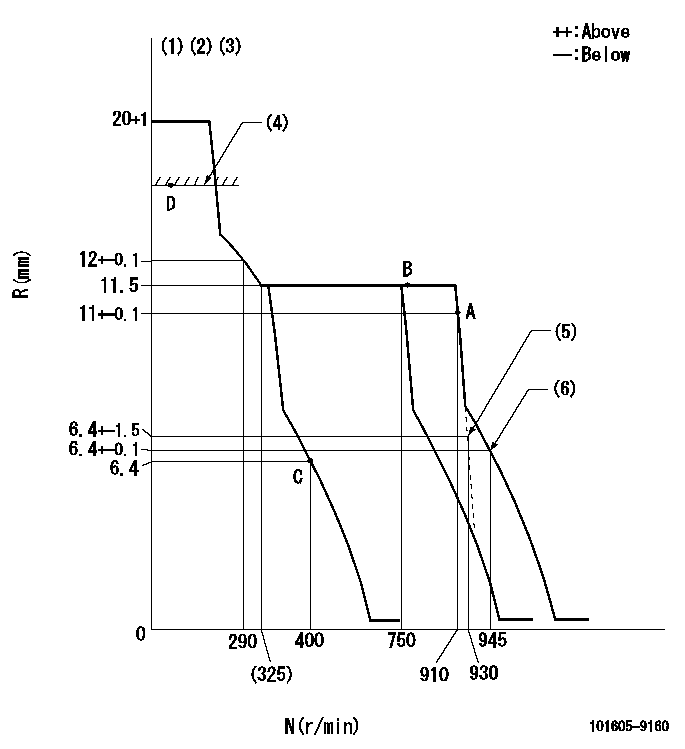

Injection quantity adjustment

Adjusting point

A

Rack position

11

Pump speed

r/min

910

910

910

Each cylinder's injection qty

mm3/st.

175

171.5

178.5

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

6.4+-0.5

Pump speed

r/min

400

400

400

Each cylinder's injection qty

mm3/st.

22.5

19.7

25.3

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

215

215

235

Fixing the lever

*

Rack limit

*

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Notch fixed: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Confirm that the rack is pulled back to R = R1 or less at solenoid operation (N = 0).

(4)RACK LIMIT

(5)Main spring setting

(6)Set idle sub-spring

----------

K=10 R1=5.9mm

----------

----------

K=10 R1=5.9mm

----------

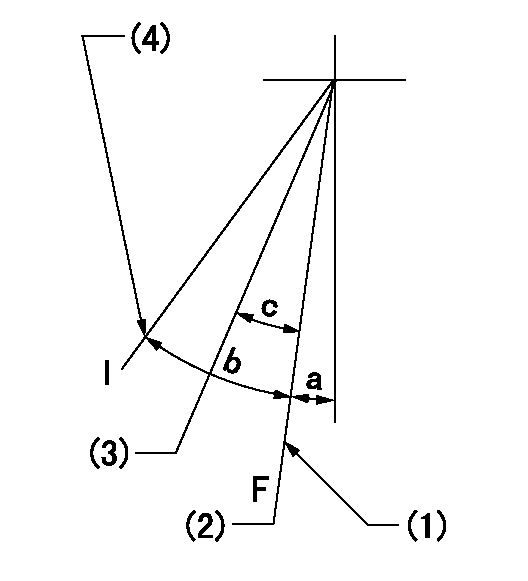

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

(2)Set the pump speed at aa

(3)When pump speed set at bb

(4)Stopper bolt setting

----------

aa=900r/min bb=750r/min

----------

a=(19deg)+-5deg b=(24deg)+-5deg c=(7deg)+-5deg

----------

aa=900r/min bb=750r/min

----------

a=(19deg)+-5deg b=(24deg)+-5deg c=(7deg)+-5deg

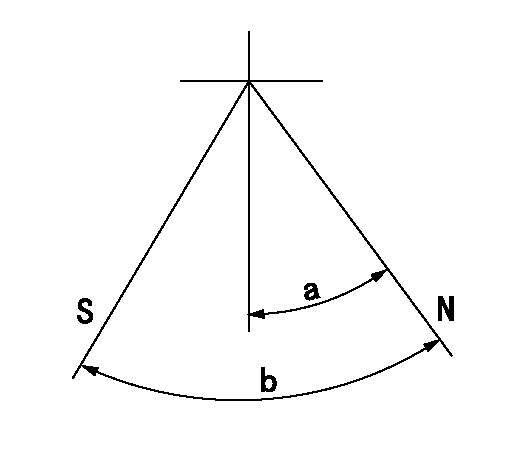

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=(26deg) b=(50deg)

----------

----------

a=(26deg) b=(50deg)

Timing setting

(1)Pump vertical direction

(2)Camshaft's key groove position at No. 6 cylinder's beginning of injection.

(3)-

(4)-

----------

----------

a=(130deg)

----------

----------

a=(130deg)

Information:

You must read and understand the warnings and instructions contained in the Safety section of this manual before performing any operation or maintenance procedures.Before proceeding with this maintenance interval, perform previous maintenance intervals and Daily maintenance requirements. Perform the maintenance at the interval listed in the Maintenance Schedule for your engine.

For maintenance of the following components in this interval, refer to the OEM manual for maintenance instructions. The following are basic suggestions and instructions.

Marine Gear

Drain Oil

With the oil warm and the engine stopped, drain the transmission.1. Remove the transmission drain plug and allow the oil to drain. Obtain an oil sample for analysis.2. Clean and install the drain plug.If a Sump Pump is Used to Drain Oil

a. Connect a drain line and container to top outlet (A) of pump.b. Be sure valve (B) on the engine oil pan line is closed. Marks on the valve must be turned at right angles to the direction of the engine oil line. c. Open valve (C) on the transmission oil line. The marks on this valve must be turned so that one mark points to the pump and the second mark points to the transmission.d. Operate the sump pump (D) handle until the transmission is empty.e. Close the sump pump valve on the oil line to the transmission.Change Filters

1. Remove transmission oil filter housing drain plug (if equipped). Allow the oil to drain into the marine gear transmission sump.2. Remove filter assembly. Disassemble and discard the element.3. Clean the filter housing and assembly parts with clean, nonflammable solvent. Clean and install the filter housing drain plug.4. Inspect any retainer plates and/or seals. Install new seals if necessary.5. Assemble and install a new filter element assembly. Tighten all bolts.6. Operate the sump pump handle until the transmission is empty. Close the sump pump valve on the oil line to the transmission.Clean the Oil Strainer

1. Remove the strainer cover and plug. Remove the spring washer, strainer screen and magnetic screen tube (if equipped).2. Wash the strainer and magnetic screen tube with clean, nonflammable solvent. If a magnet is broken, install the new magnet properly. The North (N) poles and South (S) poles of the magnets are adjacent to each other so that they repel instead of attract: S-N, N-S, S-N.3. Inspect the strainer, plug and the cover seal for damage. Use new parts if used ones are damaged.4. Install the magnetic screen tube, strainer, spring washer, seal, cover and plug.Clean the Breather (All Marine Transmissions)

1. Remove the breather.2. Clean the breather with clean, nonflammable solvent.3. Install the breather.Fill the Transmission

Be sure both sump pump valves (one to the transmission and one to the engine oil pan) are closed. Otherwise a transfer of oil may occur during sump pump operation and damage could result.

1. Be sure the marine gear drain plug has been installed, or the sump pump valve (C) on the oil line to the marine gear drain line has been closed.2. Fill the marine gear to the FULL mark on the

For maintenance of the following components in this interval, refer to the OEM manual for maintenance instructions. The following are basic suggestions and instructions.

Marine Gear

Drain Oil

With the oil warm and the engine stopped, drain the transmission.1. Remove the transmission drain plug and allow the oil to drain. Obtain an oil sample for analysis.2. Clean and install the drain plug.If a Sump Pump is Used to Drain Oil

a. Connect a drain line and container to top outlet (A) of pump.b. Be sure valve (B) on the engine oil pan line is closed. Marks on the valve must be turned at right angles to the direction of the engine oil line. c. Open valve (C) on the transmission oil line. The marks on this valve must be turned so that one mark points to the pump and the second mark points to the transmission.d. Operate the sump pump (D) handle until the transmission is empty.e. Close the sump pump valve on the oil line to the transmission.Change Filters

1. Remove transmission oil filter housing drain plug (if equipped). Allow the oil to drain into the marine gear transmission sump.2. Remove filter assembly. Disassemble and discard the element.3. Clean the filter housing and assembly parts with clean, nonflammable solvent. Clean and install the filter housing drain plug.4. Inspect any retainer plates and/or seals. Install new seals if necessary.5. Assemble and install a new filter element assembly. Tighten all bolts.6. Operate the sump pump handle until the transmission is empty. Close the sump pump valve on the oil line to the transmission.Clean the Oil Strainer

1. Remove the strainer cover and plug. Remove the spring washer, strainer screen and magnetic screen tube (if equipped).2. Wash the strainer and magnetic screen tube with clean, nonflammable solvent. If a magnet is broken, install the new magnet properly. The North (N) poles and South (S) poles of the magnets are adjacent to each other so that they repel instead of attract: S-N, N-S, S-N.3. Inspect the strainer, plug and the cover seal for damage. Use new parts if used ones are damaged.4. Install the magnetic screen tube, strainer, spring washer, seal, cover and plug.Clean the Breather (All Marine Transmissions)

1. Remove the breather.2. Clean the breather with clean, nonflammable solvent.3. Install the breather.Fill the Transmission

Be sure both sump pump valves (one to the transmission and one to the engine oil pan) are closed. Otherwise a transfer of oil may occur during sump pump operation and damage could result.

1. Be sure the marine gear drain plug has been installed, or the sump pump valve (C) on the oil line to the marine gear drain line has been closed.2. Fill the marine gear to the FULL mark on the

Have questions with 101605-9160?

Group cross 101605-9160 ZEXEL

Daewoo

Yanmar

Dpico

Daewoo

101605-9160

INJECTION-PUMP ASSEMBLY