Information injection-pump assembly

BOSCH

9 400 615 371

9400615371

ZEXEL

101605-9152

1016059152

Rating:

Include in #1:

101402-4350

as _

Cross reference number

BOSCH

9 400 615 371

9400615371

ZEXEL

101605-9152

1016059152

Zexel num

Bosch num

Firm num

Name

101605-9152

9 400 615 371

DAEWOO

INJECTION-PUMP ASSEMBLY

D1146 K

D1146 K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-1520

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

6-2-4-1-

5-3

Pre-stroke

mm

4.6

4.55

4.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 6-2 deg. 60 59.5 60.5

Cal 6-2 deg. 60 59.5 60.5

Difference between angles 2

Cal 6-4 deg. 120 119.5 120.5

Cal 6-4 deg. 120 119.5 120.5

Difference between angles 3

Cal 6-1 deg. 180 179.5 180.5

Cal 6-1 deg. 180 179.5 180.5

Difference between angles 4

Cal 6-5 deg. 240 239.5 240.5

Cal 6-5 deg. 240 239.5 240.5

Difference between angles 5

Cal 6-3 deg. 300 299.5 300.5

Cal 6-3 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.5

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

91.2

89.2

93.2

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

7.7+-0.5

Pump speed

r/min

370

370

370

Average injection quantity

mm3/st.

11.5

10

13

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Test data Ex:

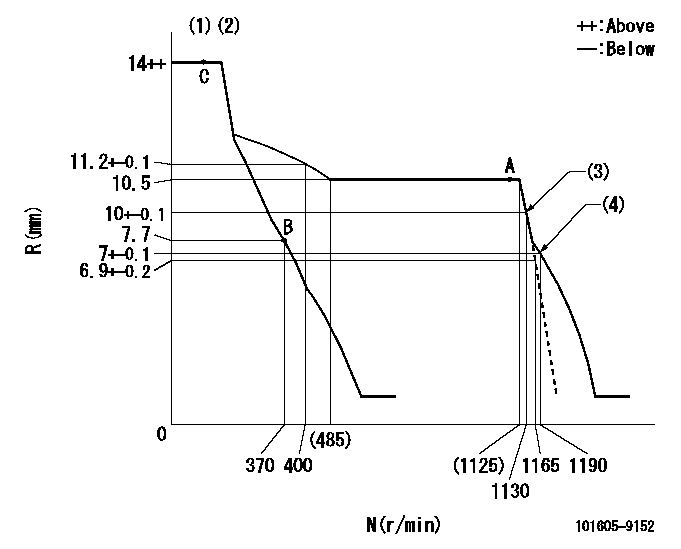

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Main spring setting

(4)Set idle sub-spring

----------

K=7

----------

----------

K=7

----------

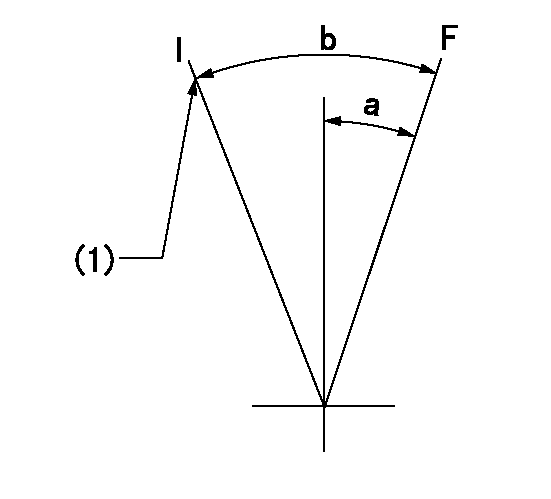

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=1deg+-5deg b=24deg+-5deg

----------

----------

a=1deg+-5deg b=24deg+-5deg

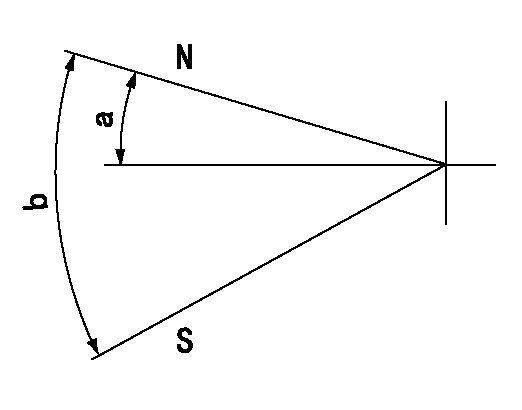

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=19deg+-5deg b=53deg+-5deg

----------

----------

a=19deg+-5deg b=53deg+-5deg

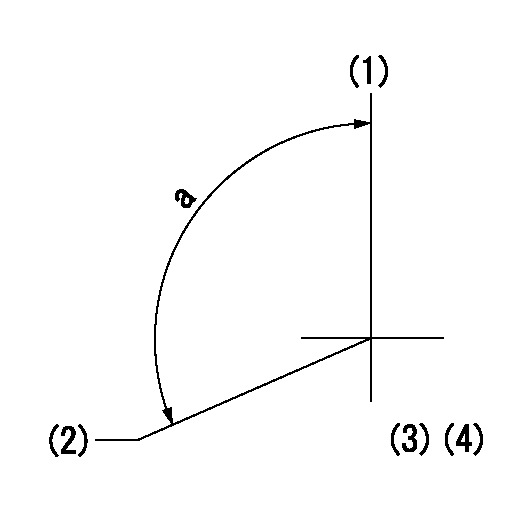

Timing setting

(1)Pump vertical direction

(2)Camshaft's key groove position at No. 6 cylinder's beginning of injection.

(3)-

(4)-

----------

----------

a=(120deg)

----------

----------

a=(120deg)

Information:

Belts, Hoses and Clamps

Inspect/Replace Accessory Drive Belts

Inspect the condition and adjustment of alternator drive belts. Examine belts for wear and replace if any signs of wear are present. Loose or worn pulley grooves cause belt slippage and low accessory drive speed.If belts are too loose, they vibrate enough to cause unnecessary wear on the belts and pulleys and possibly slip enough to cause overheating. If belts are too tight, unnecessary stresses are placed upon the pulley bearings and belts which can shorten the life of both.If one belt in a set requires replacement, always install a new matched set of belts. Never replace just the worn belt. If only the worn belt is replaced, the new belt will carry all the load, as it will not be stretched as much as the older belts. All the belts will fail in rapid succession.Adjust

1. Remove belt guard. Inspect the condition and adjustment of alternator belts and accessory drive belts, if equipped.2. To check the belt tension, apply 110 Newton (25 lb) force, perpendicular to the belt, midway between the driving and driven pulley. Measure the belt deflection. Correctly adjusted belts will deflect 13 to 20 mm (1/2 to 7/8 inch). Adjust the belt tension as required.If belt does not require replacement or adjustment, install the belt guard. If belt requires adjustment or replacement, do not install the belt guard.3. Loosen the mounting pivot bolt (1). Loosen the adjustment nut(s) (2).4. Adjust the alternator in or out by either tightening or loosening adjustment nut(s) as required to obtain the correct adjustment.5. Tighten bolts (1) and (2). Check the belt tension. Install the belt guard.If new belts are installed, check belt adjustment again after 30 minutes of engine operation. Repeat belt tightening if required.Adjust Accessory Drive Belts

If engine is equipped with any other belt driven equipment, check and adjust them as required.Inspect/Replace Hoses and Clamps

Hose replacement prior to failure is a good preventive maintenance practice. Replacing a hose before it fails reduces the chances for unscheduled downtime. By replacing a hose that is cracked, soft or leaking, major repairs will be avoided that could result in a severe engine overheating problem.* Inspect all hoses for leaks due to cracking, softness and loose clamps.* Replace hoses that are cracked or soft and tighten loose clamps. See the Torque for Standard Hose Clamps chart in the Torque Specifications section of this publication for the appropriate torque. For constant torque hose clamps, see the Torque Specifications section in this publication.Engine Valve Lash

Check/Adjust

To prevent possible injury, do not use the starting motor to turn the flywheel. Be sure the starting motors are disabled and engine cannot be started while this maintenance is being performed.Hot engine components can cause burns. Allow additional time for the engine to cool before measuring valve lash.

Measure the valve lash with the engine stopped. To obtain an accurate measurement, allow at least 20 minutes for the valves to cool to engine cylinder head and block temperature.

Initial valve lash adjustment (At First Oil

Inspect/Replace Accessory Drive Belts

Inspect the condition and adjustment of alternator drive belts. Examine belts for wear and replace if any signs of wear are present. Loose or worn pulley grooves cause belt slippage and low accessory drive speed.If belts are too loose, they vibrate enough to cause unnecessary wear on the belts and pulleys and possibly slip enough to cause overheating. If belts are too tight, unnecessary stresses are placed upon the pulley bearings and belts which can shorten the life of both.If one belt in a set requires replacement, always install a new matched set of belts. Never replace just the worn belt. If only the worn belt is replaced, the new belt will carry all the load, as it will not be stretched as much as the older belts. All the belts will fail in rapid succession.Adjust

1. Remove belt guard. Inspect the condition and adjustment of alternator belts and accessory drive belts, if equipped.2. To check the belt tension, apply 110 Newton (25 lb) force, perpendicular to the belt, midway between the driving and driven pulley. Measure the belt deflection. Correctly adjusted belts will deflect 13 to 20 mm (1/2 to 7/8 inch). Adjust the belt tension as required.If belt does not require replacement or adjustment, install the belt guard. If belt requires adjustment or replacement, do not install the belt guard.3. Loosen the mounting pivot bolt (1). Loosen the adjustment nut(s) (2).4. Adjust the alternator in or out by either tightening or loosening adjustment nut(s) as required to obtain the correct adjustment.5. Tighten bolts (1) and (2). Check the belt tension. Install the belt guard.If new belts are installed, check belt adjustment again after 30 minutes of engine operation. Repeat belt tightening if required.Adjust Accessory Drive Belts

If engine is equipped with any other belt driven equipment, check and adjust them as required.Inspect/Replace Hoses and Clamps

Hose replacement prior to failure is a good preventive maintenance practice. Replacing a hose before it fails reduces the chances for unscheduled downtime. By replacing a hose that is cracked, soft or leaking, major repairs will be avoided that could result in a severe engine overheating problem.* Inspect all hoses for leaks due to cracking, softness and loose clamps.* Replace hoses that are cracked or soft and tighten loose clamps. See the Torque for Standard Hose Clamps chart in the Torque Specifications section of this publication for the appropriate torque. For constant torque hose clamps, see the Torque Specifications section in this publication.Engine Valve Lash

Check/Adjust

To prevent possible injury, do not use the starting motor to turn the flywheel. Be sure the starting motors are disabled and engine cannot be started while this maintenance is being performed.Hot engine components can cause burns. Allow additional time for the engine to cool before measuring valve lash.

Measure the valve lash with the engine stopped. To obtain an accurate measurement, allow at least 20 minutes for the valves to cool to engine cylinder head and block temperature.

Initial valve lash adjustment (At First Oil

Have questions with 101605-9152?

Group cross 101605-9152 ZEXEL

Daewoo

Yanmar

Dpico

Daewoo

101605-9152

9 400 615 371

INJECTION-PUMP ASSEMBLY

D1146

D1146