Information injection-pump assembly

BOSCH

9 400 611 258

9400611258

ZEXEL

101605-9100

1016059100

Rating:

Service parts 101605-9100 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

14.7{150}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 611 258

9400611258

ZEXEL

101605-9100

1016059100

Zexel num

Bosch num

Firm num

Name

9 400 611 258

DAEWOO

INJECTION-PUMP ASSEMBLY

DB58 K 14BE INJECTION PUMP ASSY PE6A PE

DB58 K 14BE INJECTION PUMP ASSY PE6A PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

9.4

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

67.3

66.3

68.3

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

8.7

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

58.9

56.9

60.9

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

-

Rack position

6.5+-0.5

Pump speed

r/min

385

385

385

Average injection quantity

mm3/st.

9.4

8.1

10.7

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_04

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

90

90

110

Fixing the lever

*

Rack limit

*

Test data Ex:

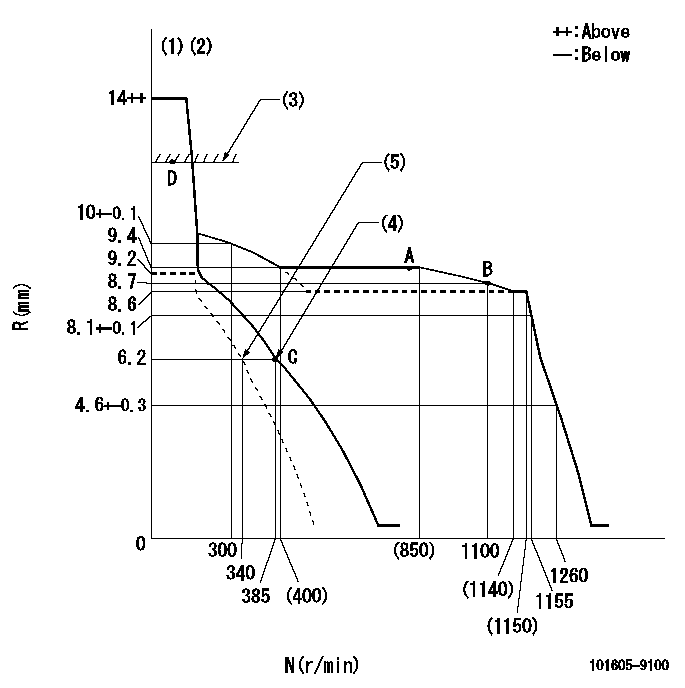

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Main spring setting

(5)Set idle sub-spring

----------

K=6

----------

----------

K=6

----------

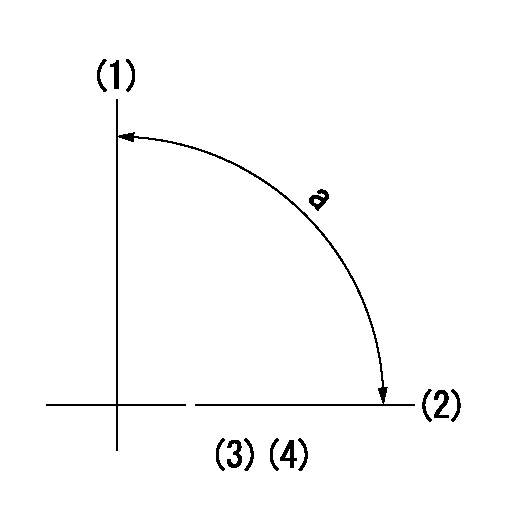

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=(2deg)+-5deg b=(22deg)+-5deg

----------

----------

a=(2deg)+-5deg b=(22deg)+-5deg

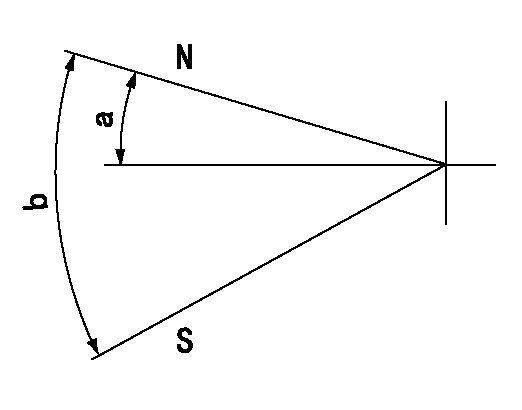

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=19deg+-5deg b=53deg+-5deg

----------

----------

a=19deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'CC' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=20deg

----------

a=(90deg)

----------

aa=20deg

----------

a=(90deg)

Information:

Alarm Contactors

The engine is equipped with standard electrical overspeed switch which uses a flywheel housing mounted magnetic pickup. The magnetic pickup will close the circuit and the alarm will be activated when the engine exceeds the setpoint rpm. This engine may be equipped with a Coolant Level Alarm contactor. An Oil Pressure and Coolant Temperature Alarm contactors are optional.Alarm switches are electrically connected to an indicator light, bell or horn. When an alarm is activated, it is an indication of a potential problem and corrective measures must be taken before the situation becomes an emergency. While these alarm switches do not stop the engine, the problem should be investigated and corrective action taken to prevent engine damage.The alarm will continue until the condition is corrected. Then the light will turn off and the bell or horn will be silenced.To silence the bell or horn while repairs are being made, a two-way switch and a red indicator light may be installed. The red indicator light will come on when the alarm is turned off. The red light will stay on, to indicate that the engine is NOT protected, if the switch is left in the OFF position after the repairs have been made.Low Oil Pressure Switch (Early Engines)

The switch will not protect the system from rapid oil loss, caused by failures such as line breakage.

Low oil pressure switchThis device is usually mounted on the side of the engine. The oil lines are connected to the switch. Low oil pressure closes the switch. To reset the switch, push the RESET button in the junction box until it latches. After the engine starts and develops oil pressure, the button will move to the extended (running) position.

The button must be in the RUN position to protect the engine. If the button remains in the OFF position, the engine oil pump may not be developing normal oil pressure and proper checks should be made.

Manually operated systems require resetting of this switch before starting. Automatic start-stop systems use a pressure switch which resets itself.Low Oil Pressure Switch (Later Engines)

This switch does NOT require resetting. This switch is mounted in the oil manifold on the side of the block with the oil lines connected to it. Low oil pressure opens this switch to disconnect the electrical circuit to the shutoff solenoid. This prevents the battery from continuously energizing the solenoid while the engine is stopped.This switch is also used with the electric governor. On start-up, oil pressure will close the switch to allow the electric governor to increase engine speed.Marine Transmission Oil Temperature Switch

The switch is typically located in the oil line between the oil pump and the oil strainer or the oil filter of the marine transmission.High Coolant Water Temperature Switch

Coolant level must be maintained in order for the alarm to function, because the sensing element must be submerged in the coolant to operate. The alarm cannot actuate if the coolant level is low.

The switch is located in the water temperature regulator housing. Excessive

The engine is equipped with standard electrical overspeed switch which uses a flywheel housing mounted magnetic pickup. The magnetic pickup will close the circuit and the alarm will be activated when the engine exceeds the setpoint rpm. This engine may be equipped with a Coolant Level Alarm contactor. An Oil Pressure and Coolant Temperature Alarm contactors are optional.Alarm switches are electrically connected to an indicator light, bell or horn. When an alarm is activated, it is an indication of a potential problem and corrective measures must be taken before the situation becomes an emergency. While these alarm switches do not stop the engine, the problem should be investigated and corrective action taken to prevent engine damage.The alarm will continue until the condition is corrected. Then the light will turn off and the bell or horn will be silenced.To silence the bell or horn while repairs are being made, a two-way switch and a red indicator light may be installed. The red indicator light will come on when the alarm is turned off. The red light will stay on, to indicate that the engine is NOT protected, if the switch is left in the OFF position after the repairs have been made.Low Oil Pressure Switch (Early Engines)

The switch will not protect the system from rapid oil loss, caused by failures such as line breakage.

Low oil pressure switchThis device is usually mounted on the side of the engine. The oil lines are connected to the switch. Low oil pressure closes the switch. To reset the switch, push the RESET button in the junction box until it latches. After the engine starts and develops oil pressure, the button will move to the extended (running) position.

The button must be in the RUN position to protect the engine. If the button remains in the OFF position, the engine oil pump may not be developing normal oil pressure and proper checks should be made.

Manually operated systems require resetting of this switch before starting. Automatic start-stop systems use a pressure switch which resets itself.Low Oil Pressure Switch (Later Engines)

This switch does NOT require resetting. This switch is mounted in the oil manifold on the side of the block with the oil lines connected to it. Low oil pressure opens this switch to disconnect the electrical circuit to the shutoff solenoid. This prevents the battery from continuously energizing the solenoid while the engine is stopped.This switch is also used with the electric governor. On start-up, oil pressure will close the switch to allow the electric governor to increase engine speed.Marine Transmission Oil Temperature Switch

The switch is typically located in the oil line between the oil pump and the oil strainer or the oil filter of the marine transmission.High Coolant Water Temperature Switch

Coolant level must be maintained in order for the alarm to function, because the sensing element must be submerged in the coolant to operate. The alarm cannot actuate if the coolant level is low.

The switch is located in the water temperature regulator housing. Excessive