Information injection-pump assembly

BOSCH

9 400 610 214

9400610214

ZEXEL

101605-3561

1016053561

KOMATSU

6138721340

6138721340

Rating:

Service parts 101605-3561 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

6138-12-3300

12.

Open Pre:MPa(Kqf/cm2)

24.5{250}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 610 214

9400610214

ZEXEL

101605-3561

1016053561

KOMATSU

6138721340

6138721340

Zexel num

Bosch num

Firm num

Name

101605-3561

9 400 610 214

6138721340 KOMATSU

INJECTION-PUMP ASSEMBLY

S6D110 * K 14BE INJECTION PUMP ASSY PE6A PE

S6D110 * K 14BE INJECTION PUMP ASSY PE6A PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4

3.95

4.05

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

9.8

Pump speed

r/min

1050

1050

1050

Average injection quantity

mm3/st.

78.7

77.7

79.7

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

8+-0.5

Pump speed

r/min

425

425

425

Average injection quantity

mm3/st.

13.1

11.9

14.3

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Test data Ex:

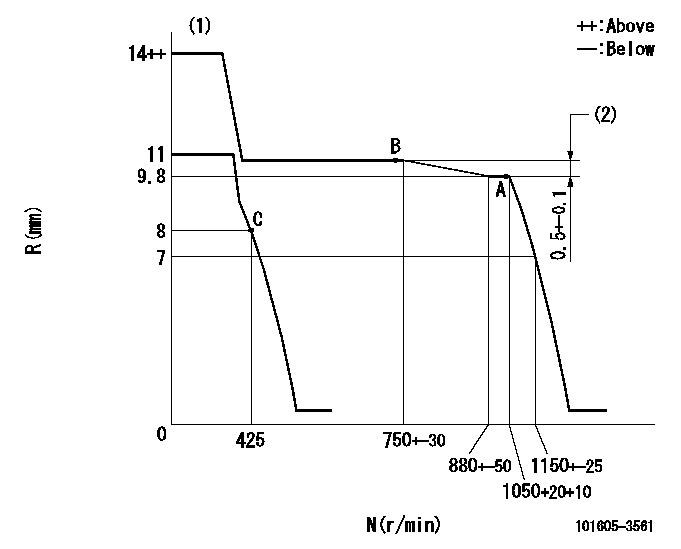

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Rack difference between N = N1 and N = N2

----------

K=18 N1=1050r/min N2=700r/min

----------

----------

K=18 N1=1050r/min N2=700r/min

----------

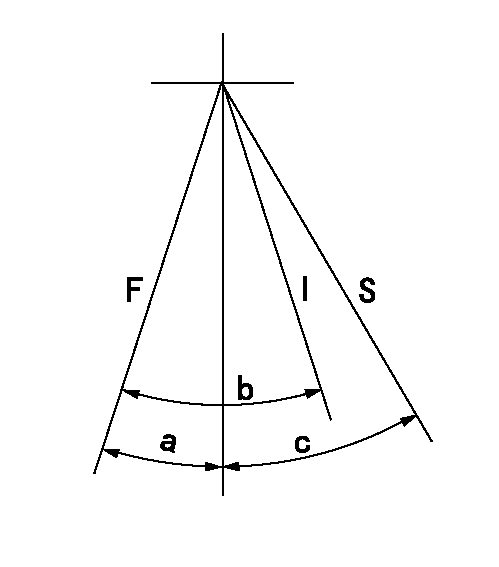

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=16deg+-5deg b=26deg+-5deg c=32deg+-3deg

----------

----------

a=16deg+-5deg b=26deg+-5deg c=32deg+-3deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(0deg)

----------

----------

a=(0deg)

Information:

Engine Crankshaft Will Not Turn

Possible Causes/Corrections

Low Or No Battery VoltageCheck battery voltage. If battery voltage is less than 8 volts for a 12 volt system, or 16 volts for a 24 volt system, put a charge to the battery. If battery will not hold a charge, load test the battery as shown in the Electrical System of the Testing and Adjusting Section of this Service Manual. Defective Switch, Defective Wiring Or Connection In Swith CircuitWith ignition switch in START position, check voltage at switch connection on starter solenoid. If there is no voltage, or if the voltage is low at this connection, check wiring, connections, ignition switch, and magnetic switch (if used). Defective Cable Or Connection; Battery To StarterWith ignition switch in the START position, check voltage at connection of battery cable to starter. If there is no voltage, or if the voltage is low at this connection and there is good voltage at the battery, check for defective cable or connection between the battery and the starter. Defective Starter SolenoidRemove and repair a solenoid which does not work when voltage is correct at both the battery and ignition switch connections. Defective Starter MotorIf the solenoid works and the starter motor does not turn the crankshaft, the starter motor is defective. Before removing the starter motor, turn the crankshaft by hand to be sure a mechanical failure inside the engine, transmission, or power take-off is not preventing the crankshaft from turning. If crankshaft turns freely by hand, engage the starter motor again. If the starter motor still will not work, remove the starter motor and repair it, or install a new starter motor. Transmission Or Power Take-off (if so equipped) Problem Prevents Crankshaft From TurningIf crankshaft can not be turned by hand, disconnect the transmission and power take-off. If crankshaft will now turn, find the cause of the problem in the transmission or power take-off and make necessary corrections. Inside Problem Prevents Engine Crankshaft From TurningIf the crankshaft can not be turned after disconnecting the transmission and power take-off, remove the fuel nozzles and check for fluid in the cylinders while turning the crankshaft. If fluid in the cylinders is not the problem, the engine must be disassembled to check for other inside problems. Some of these inside problems are bearing seizure, piston seizure, and valves making contact with pistons.Engine Crankshaft Turns Too Slowly

Possible Causes/Corrections

Low Battery VoltageCheck battery voltage. If battery voltage is less than 8 volts for a 12 volt system, or 16 volts for a 24 volt system, put a charge to the battery. If the battery will not hold a charge, load test the battery as shown in the Electrical System of the Testing and Adjusting Section of this Service Manual. Defective Cable Or Connection; Battery To StarterWith switch in START position, check voltage at battery cable connection to starter. If voltage is low at this connection and there is good voltage at the battery, check for defective cable or connection between the battery and

Possible Causes/Corrections

Low Or No Battery VoltageCheck battery voltage. If battery voltage is less than 8 volts for a 12 volt system, or 16 volts for a 24 volt system, put a charge to the battery. If battery will not hold a charge, load test the battery as shown in the Electrical System of the Testing and Adjusting Section of this Service Manual. Defective Switch, Defective Wiring Or Connection In Swith CircuitWith ignition switch in START position, check voltage at switch connection on starter solenoid. If there is no voltage, or if the voltage is low at this connection, check wiring, connections, ignition switch, and magnetic switch (if used). Defective Cable Or Connection; Battery To StarterWith ignition switch in the START position, check voltage at connection of battery cable to starter. If there is no voltage, or if the voltage is low at this connection and there is good voltage at the battery, check for defective cable or connection between the battery and the starter. Defective Starter SolenoidRemove and repair a solenoid which does not work when voltage is correct at both the battery and ignition switch connections. Defective Starter MotorIf the solenoid works and the starter motor does not turn the crankshaft, the starter motor is defective. Before removing the starter motor, turn the crankshaft by hand to be sure a mechanical failure inside the engine, transmission, or power take-off is not preventing the crankshaft from turning. If crankshaft turns freely by hand, engage the starter motor again. If the starter motor still will not work, remove the starter motor and repair it, or install a new starter motor. Transmission Or Power Take-off (if so equipped) Problem Prevents Crankshaft From TurningIf crankshaft can not be turned by hand, disconnect the transmission and power take-off. If crankshaft will now turn, find the cause of the problem in the transmission or power take-off and make necessary corrections. Inside Problem Prevents Engine Crankshaft From TurningIf the crankshaft can not be turned after disconnecting the transmission and power take-off, remove the fuel nozzles and check for fluid in the cylinders while turning the crankshaft. If fluid in the cylinders is not the problem, the engine must be disassembled to check for other inside problems. Some of these inside problems are bearing seizure, piston seizure, and valves making contact with pistons.Engine Crankshaft Turns Too Slowly

Possible Causes/Corrections

Low Battery VoltageCheck battery voltage. If battery voltage is less than 8 volts for a 12 volt system, or 16 volts for a 24 volt system, put a charge to the battery. If the battery will not hold a charge, load test the battery as shown in the Electrical System of the Testing and Adjusting Section of this Service Manual. Defective Cable Or Connection; Battery To StarterWith switch in START position, check voltage at battery cable connection to starter. If voltage is low at this connection and there is good voltage at the battery, check for defective cable or connection between the battery and

Have questions with 101605-3561?

Group cross 101605-3561 ZEXEL

Komatsu

101605-3561

9 400 610 214

6138721340

INJECTION-PUMP ASSEMBLY

S6D110

S6D110