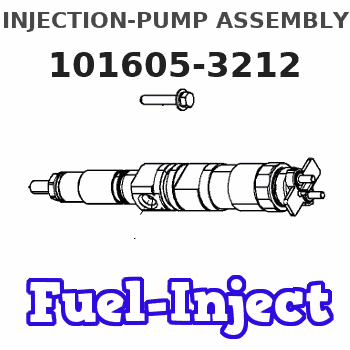

Information injection-pump assembly

BOSCH

9 400 615 331

9400615331

ZEXEL

101605-3212

1016053212

KOMATSU

6136721153

6136721153

Rating:

Service parts 101605-3212 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

6137-12-3200

12.

Open Pre:MPa(Kqf/cm2)

22.1{225}

15.

NOZZLE SET

Include in #1:

101605-3212

as INJECTION-PUMP ASSEMBLY

Include in #2:

104740-6021

as _

Cross reference number

Zexel num

Bosch num

Firm num

Name

9 400 615 331

6136721153 KOMATSU

INJECTION-PUMP ASSEMBLY

6D105 K 14BE INJECTION PUMP ASSY PE6A PE

6D105 K 14BE INJECTION PUMP ASSY PE6A PE

Information:

Keep all parts clean from contaminants. Contaminants put into the system may cause rapid wear and shortened component life.

1. Loosen hose clamps and slide hose (1) down on the tube assembly. 2. Remove tube assembly (4).3. Disconnect hose assembly (3), loosen two clamps and slide hose (2) on tube assembly. 4. Remove bolts (5). 5. Remove the supply tube (6) and drain tube (7) and the gaskets. 6. Disconnect tube assembly (8) from the aftercooler housing and remove bolts (9).7. Attach a hoist to the cylinder head lift brackets. 8. Remove head bolts (10) and the cylinder head from the engine block. The weight of the cylinder head assembly is 177 kg (390 lb).

Do not set the cylinder head on a flat surface because of possible damage to the fuel injection nozzle tips.

Install Cylinder Head

When the cylinder head is removed, a new spacer plate gasket must be installed. See the topic, Remove And Install Spacer Plate, in this manual. 1. Clean the surfaces of the cylinder head and the cylinder block that make contact with each other. Make sure the surfaces are clean and dry. Install a new dry gasket (2) on the cylinder block.2. Fasten a hoist to the cylinder head (1) and put it on position on the cylinder block.3. Put 6V4876 Molykote Lubricant on all the head bolts and rocker shaft bolts except bolt (25). Install the head bolts and washers that hold the head in place. Do not tighten bolts at this time.4. Loosen the adjusting screws on the rocker arms for valve clearance. This will prevent a bent valve or push rod at installation. 5. Install push rods (4) and rocker shaft assembly (3). Install the bolts and washers that hold the rocker shaft in place. 6. Tighten the bolts as follows:a. Tighten bolts 1 through 26 in number sequence to a torque of 155 N m (115 lb ft).b. Tighten bolts 1 through 26 again in number sequence to a torque of 250 17 N m (185 13 lb ft).c. Tighten bolts 1 through 26 again in number sequence (hand tighten only) to a torque of 250 17 N m (185 13 lb ft).d. Tighten bolts A through G in letter sequence (hand tighten only) to a torque of 43 7 N m (32 5 lb ft). 6. Make an adjustment until the intake valve clearance is 0.38 mm (.015 in) and the exhaust valve clearance is 0.64 mm (.025 in). Tighten the locknuts (5) for the adjusting screws to a torque of 29 7 N m (21 5 lb ft).7. Connect tube assembly (6) and install the bolts to fasten clips (7). 8. Inspect the turbocharger cartridge gaskets and make replacements if necessary. Install gaskets and the turbocharger supply tube assembly (8) and drain tube assembly (9). 9. Make sure the gasket for the water pump bypass elbow is in good condition and install two bolts (11) to fasten elbow (12) to cylinder