Information injection-pump assembly

BOSCH

F 019 Z10 731

f019z10731

ZEXEL

101605-0210

1016050210

ISUZU

1156034580

1156034580

Rating:

Service parts 101605-0210 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

18.1(185)

15.

NOZZLE SET

Include in #1:

101605-0210

as INJECTION-PUMP ASSEMBLY

Include in #2:

104746-1041

as _

Cross reference number

BOSCH

F 019 Z10 731

f019z10731

ZEXEL

101605-0210

1016050210

ISUZU

1156034580

1156034580

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-4120

Overflow valve opening pressure

kPa

255

255

255

Overflow valve opening pressure

kgf/cm2

2.6

2.6

2.6

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.2

4.15

4.25

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.6

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

101

99.5

102.5

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Boost pressure

kPa

113

113

Boost pressure

mmHg

850

850

Injection quantity adjustment_02

Adjusting point

-

Rack position

7.7+-0.5

Pump speed

r/min

450

450

450

Average injection quantity

mm3/st.

12

10.7

13.3

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

E

Rack position

10.8++

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

105

100

110

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

R1-1.65

Boost pressure

kPa

17.3

13.3

21.3

Boost pressure

mmHg

130

100

160

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

R1(10.6)

Boost pressure

kPa

100

93.3

106.7

Boost pressure

mmHg

750

700

800

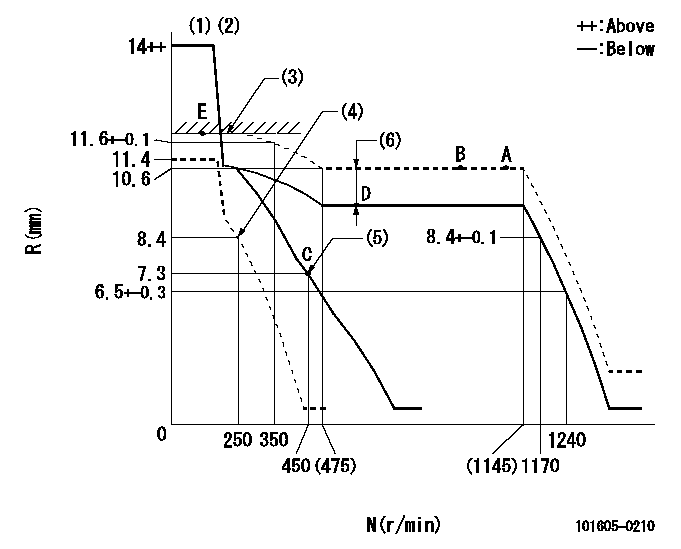

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Main spring setting

(6)Boost compensator stroke: BCL

----------

K=14 BCL=1.65+-0.1mm

----------

----------

K=14 BCL=1.65+-0.1mm

----------

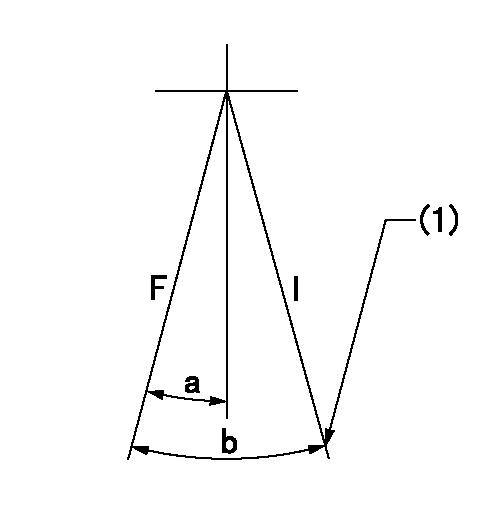

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=11deg+-5deg b=21deg+-5deg

----------

----------

a=11deg+-5deg b=21deg+-5deg

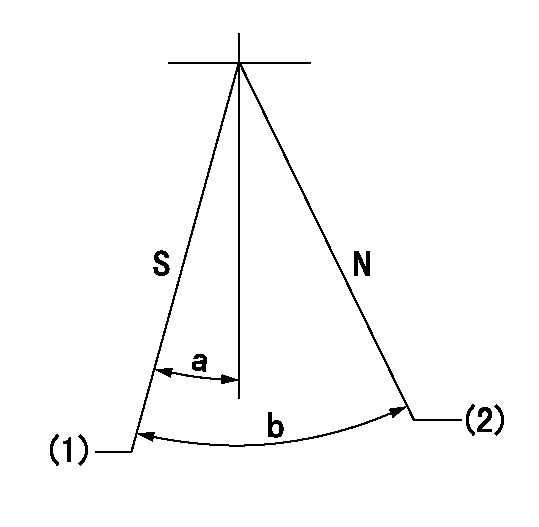

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Pump speed aa and rack position bb (to be sealed at delivery)

(2)Normal

----------

aa=0r/min bb=1-0.5mm

----------

a=32deg+-5deg b=(55deg)

----------

aa=0r/min bb=1-0.5mm

----------

a=32deg+-5deg b=(55deg)

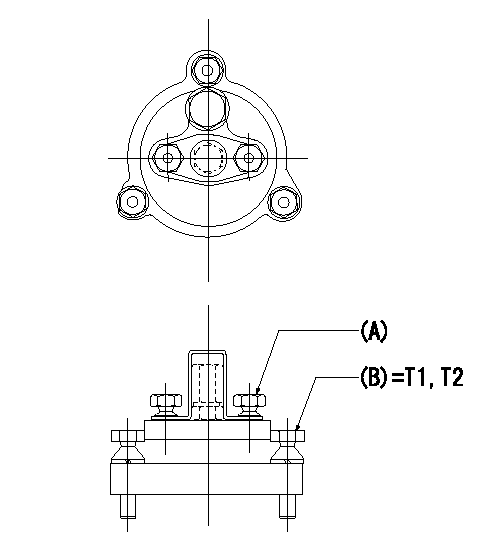

0000001501 TAMPER PROOF

Tamperproofing-equipped boost compensator cover installation procedure

(A): After adjusting the boost compensator, assemble then tighten the bolts to remove the heads.

(B): Specified torque

(1)Before adjusting the governor and the boost compensator, tighten the screw to the specified torque.

(Tightening torque T = T1 maximum)

(2)After adjusting the governor and the boost compensator, tighten to the specified torque to break off the bolt heads.

(Tightening torque T = T2)

----------

T1=2.5N-m(0.25kgf-m) T2=2.9~4.4N-m(0.3~0.45kgf-m)

----------

----------

T1=2.5N-m(0.25kgf-m) T2=2.9~4.4N-m(0.3~0.45kgf-m)

----------

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'CC' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=7.5deg

----------

a=(110deg)

----------

aa=7.5deg

----------

a=(110deg)

Information:

Intake and exhaust valve stems are to be coated with 8T2998 Break-in Lubricant prior to installation in the cylinder head.(1) Exhaust valve.(2) Intake valve.(3) 7C4273 Spring for valves. Free length ... 71.0 mm (2.80 in)Assembled length ... 65.86 mm (2.593 in)Load at assembled length ... 217 22 N (49 5 lb)Minimum operating length ... 50.7 mm (2.00 in)Load at minimum operating length ... 858 40 N (193 9 lb)(4) Height to top of valve guides ... 23.0 0.5 mm (.906 .020 in) Install valve guide with 12.065 mm diameter on spring side of the head.Assemble with seal seated against top of valve guide.(5) Diameter of valve stems (new) ... 8.000 0.008 mm (.3150 .0003 in) "Use again" minimum diameter of valve stems ... 7.965 mm (.3136 in)Bore in valve guides with guides installed in head ... 8.045 0.010 mm (.3167 .0004 in)"Use again" maximum bore in valve guides with guides installed in head ... 8.080 mm (.3181 in)(6) Diameter of valve head: Intake valve ... 47.00 0.13 mm (1.850 .005 in)Exhaust valve ... 40.00 0.13 mm (1.575 .005 in)(7) Angle of valve faces: Intake valve ... 29 1/4 1/4°Exhaust valve ... 45 1/4° (8) Diameter of valve seat inserts: Intake valve ... 50.000 0.013 mm (1.9685 .0005 in)Exhaust valve ... 43.000 0.013 mm (1.6929 .0005 in)Bore in head for valve seat insert:Intake valve ... 49.931 0.013 mm (1.9658 .0005 in)Exhaust valve ... 42.931 0.013 mm (1.6902 .0005 in)Valve seat insert must be shrunk by reduced temperature before installing in head.(9) Angle of valve seat inserts: Intake valve ... 30 1°Exhaust valve ... 45 1°(10) Depth of bore in head for valve seat insert ... 10.00 0.13 mm (.394 .005 in)(11) Outside diameter of the seating face of the valve seat insert: Intake valve ... 45.880 0.085 mm (1.8063 .0033 in)Exhaust valve ... 39.135 0.046 mm (1.5407 .0018 in)(12) "Use again" thickness of valve lip: Intake valve ... 1.80 mm (.071 in)Exhaust valve ... 1.50 mm (.059 in)