Information injection-pump assembly

ZEXEL

101603-9410

1016039410

Rating:

Cross reference number

ZEXEL

101603-9410

1016039410

Zexel num

Bosch num

Firm num

Name

101603-9410

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.4

3.35

3.45

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

11.8

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

66.3

64.7

67.9

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

9.5

7.7

11.3

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.8)

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

66.3

65.3

67.3

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1-0.2

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

73

69.8

76.2

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1(11.8)

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

83.9

79.9

87.9

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

84

84

94

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

850--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

800

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1500

Advance angle

deg.

4

3.5

4.5

Remarks

Finish

Finish

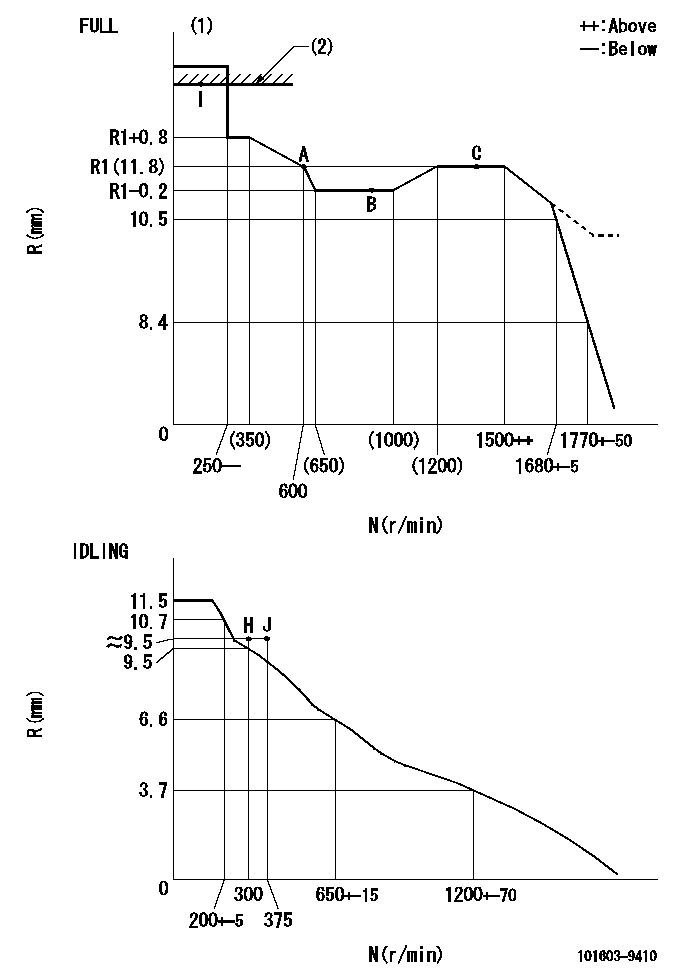

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)RACK LIMIT

----------

T1=C43

----------

----------

T1=C43

----------

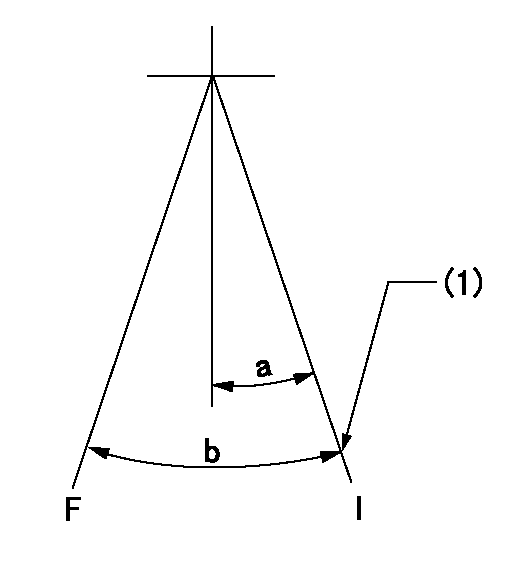

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H'

----------

----------

a=26.5deg+-5deg b=40deg+-3deg

----------

----------

a=26.5deg+-5deg b=40deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=20deg+-5deg b=40deg+-5deg

----------

----------

a=20deg+-5deg b=40deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(60deg)

----------

----------

a=(60deg)

Information:

Do not heat the gear with a torch. Do not heat the gear to a temperature of more than 315°C (600°F). Heating the gear with a torch or to a temperature of more than 315°C (600°F) may cause the two drive dowels for the automatic timing advance to loosen and come out of the gear.

2. Align slot in gear hub with the pin in the camshaft. Install the gear on the camshaft with timing mark on gear aligned with timing mark on crankshaft gear. Be sure the gear is completely seated against the shoulder of the camshaft.

Do not drive the gear on the camshaft.

3. Align holes in weights with dowels in gear and install the automatic timing advance.4. Align pin (3) in washer with hole (4) in camshaft and install washer (2).5. Install screw (1) and tighten to 7.9 0.6 N m (70 5 lb in). Stake screw in two places.

Installing Washer

(2) Washer. (3) Pin. (4) Hole.

Stake screw (1) carefully. Heavy blows on washer or screw can force the shaft extension too far into the camshaft and eliminate all end clearance.

6. After screw (1) is staked, the gear and weight assembly requires 0.08 to 0.94 mm (.003 to .037 in) end clearance to prevent binding against the washer, camshaft end or camshaft gear.

Staking Screw

(1) Screw.Camshaft Bearings Removal and Installation

Remove camshaft bearings using the 1P5544 Washer (1) and 0S0509 Bolts (2), from the 1P5545 Adapter Group, in conjunction with the 8S2241 Camshaft Bearing Removal and Installation Group, and the 8H0684 Ratchet Box Wrench.

Installing Washer

(1) 1P5544 Washer. (2) 0S0509 Bolt.With removal tools installed on cylinder block, remove bearings.

Removing Camshaft BearingsUse the 1P5545 Adapter Group in conjunction with the 8S2241 Camshaft Bearing Removal and Installation Group, and the 8S0684 Ratchet Box Wrench to install camshaft bearing.

Installing Camshaft BearingsThe 1P5545 Adapter Group pilots in the camshaft bearing bore and also pilots the bearing into the bore. This insures bearing alignment. Install bearings from chamfered side of the bore and align oil hole in bearings with oil holes in cylinder block.To install the camshaft front bearing, it is necessary to machine a notch in the 8S8289 Tube (3) for clearance of the boss that projects above the camshaft bearing bore. Machine the notch 38.1 mm (1.50 in) wide, 9.5 mm (.37 in) deep, with a 3.2 mm (.13 in) radius or chamfer in the corners and on the edges.

Notch In Tube

(3) 8S8289 Tube. (4) 8S8288 Cone. (5) Notch.Invert the 8S8288 Cone (4) and install it in the 8S8289 Tube (3) for installation of the camshaft front bearing.

Installing Camshaft Front Bearing

(3) 8S8289 Tube. (4) 8S8288 Cone.Engine Test Procedure

Lubrication For A Rebuilt Engine

It is very important for a rebuilt engine to have "adequate" (needed) lubrication during the first seconds of operation. A "dry start" (without needed lubrication) on a rebuilt engine can cause bearing damage.When an engine is rebuilt with new parts, oil is put on each part as it is installed. This is generally enough lubrication for engine start-up. However, this lubrication

Have questions with 101603-9410?

Group cross 101603-9410 ZEXEL

Nissan-Diesel

101603-9410

INJECTION-PUMP ASSEMBLY