Information injection-pump assembly

ZEXEL

101603-9310

1016039310

Rating:

Cross reference number

ZEXEL

101603-9310

1016039310

Zexel num

Bosch num

Firm num

Name

101603-9310

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.4

3.35

3.45

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

9.8

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

58.9

57.9

59.9

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

R1(10)

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

80.6

79.6

81.6

Max. variation between cylinders

%

0

-5

5

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

7.9+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

8.3

6.5

10.1

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Injection quantity adjustment_04

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

80

80

Fixing the lever

*

Remarks

After startup boost setting

After startup boost setting

Timer adjustment

Pump speed

r/min

850--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

800

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1500

Advance angle

deg.

4

3.5

4.5

Remarks

Finish

Finish

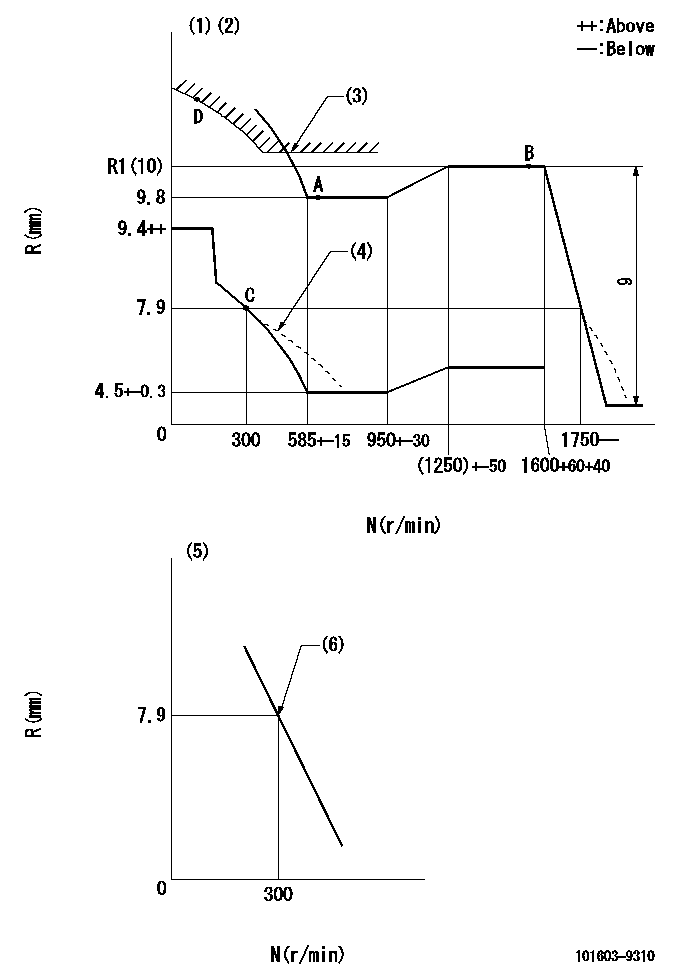

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)Excess fuel setting for starting: SXL

(4)Damper spring setting: DL

(5)Variable speed specification: idling adjustment

(6)Main spring setting

----------

RT=1 TH=1.7mm SXL=R1+0.2mm DL=7-0.2mm

----------

----------

RT=1 TH=1.7mm SXL=R1+0.2mm DL=7-0.2mm

----------

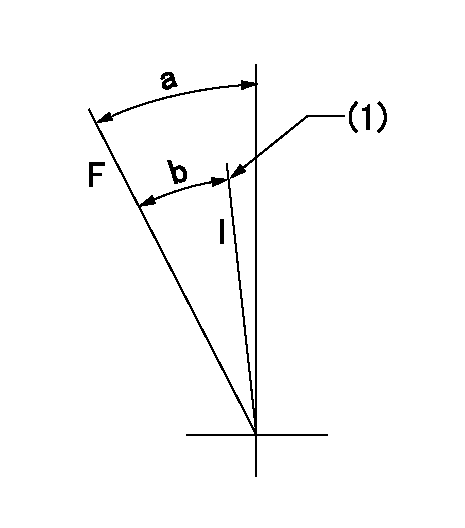

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=(24deg)+-5deg b=(20deg)+-5deg

----------

----------

a=(24deg)+-5deg b=(20deg)+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=18deg+-5deg b=19.5deg+-3deg

----------

----------

a=18deg+-5deg b=19.5deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the pin at R = aa

----------

aa=20mm

----------

a=40deg+-5deg b=71deg+-5deg

----------

aa=20mm

----------

a=40deg+-5deg b=71deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(60deg)

----------

----------

a=(60deg)

Information:

Before any service work is done on the fuel system, the outer surface of the injection pump housing must be clean.

The fuel injection pump housing and governor has been removed from the engine for illustration purposes. 1. Remove flange (1) and the flange assembly from the cover.2. Remove cover (2) from the pump housing. 3. Remove the bypass valve (3) and springs from the pump housing.4. Install tooling (A) on the fuel injection pump and loosen the bushing from the pump housing. Do not loosen screws (4) that hold the levers to the shaft when the pumps are removed or installed. If the levers are moved, fuel pump calibration will be changed. 5. Remove the fuel injection pump (5) from the pump housing. The sleeve on the plunger will slide off the lever as the pump is removed.6. Do Steps 4 and 5 for the remainder of the pumps.Install Fuel Injection Pumps

1. Turn the camshaft until the lifter for the pump to be installed is at its lowest position.2. Install the fuel injection pump (1) in the bore of the pump housing. 3. The sleeve (2) will be engaged with the lever when the pump is installed correctly.

If the levers have been moved on the shaft, fuel pump calibration must be made. (See TESTING AND ADJUSTING).

4. Tighten the bushing with tooling (A) to a torque of 80 7 N m (60 5 lb.ft.).5. Do Steps 1 through 4 for the remainder of the pumps. 6. Install the bypass valve and spring (3) in the pump housing.7. Install the cover (5) on the pump housing. Be sure the spring (3) is in the bore in the cover. 8. Install the flange (4) and the flange assembly on the cover.Disassemble Fuel Injection Pumps

1. Remove bushing (1) and O-ring seal (7) from bonnet (2).2. Remove ring (3) from the bonnet and barrel (4). 3. Remove check valve assembly (9) and spring (8) from the bonnet.4. Remove spring (10) and retainer washer (5).

Keep the plunger and sleeve with their respective barrel for installation. Do not use plungers, sleeves and barrels with other plungers, sleeves and barrels.

5. Remove plunger (11) and sleeve (6).Assemble Fuel Injection Pumps

1. Install the sleeve (4), plunger (5), spring (2) and washer (3) on barrel (1).

Be sure the sleeve and plunger are installed in their original barrel and the large hole in the plunger is up. The sleeve must be installed with the thin flange up.

2. Install the check valve assembly and spring in the bonnet. Connect the barrel and bonnet with the ring. Install the seal and bushing on the bonnet. end by:a) install fuel injection pumps

Have questions with 101603-9310?

Group cross 101603-9310 ZEXEL

Nissan-Diesel

101603-9310

INJECTION-PUMP ASSEMBLY