Information injection-pump assembly

ZEXEL

101603-9190

1016039190

Rating:

Service parts 101603-9190 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

21.6(220)

15.

NOZZLE SET

Cross reference number

ZEXEL

101603-9190

1016039190

Zexel num

Bosch num

Firm num

Name

101603-9190

DPICO

INJECTION-PUMP ASSEMBLY

KH * Q

KH * Q

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-0920

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.1

3.07

3.13

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

A

Rack position

6.5

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

58.5

57.5

59.5

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

5+-0.5

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

8

7

9

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

C

Rack position

13.7+-0.

5

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

125

125

135

Fixing the lever

*

Rack limit

*

Injection quantity adjustment_04

Adjusting point

E

Rack position

6.8

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

51

49

53

Fixing the lever

*

Timer adjustment

Pump speed

r/min

1250

Advance angle

deg.

0.5

Timer adjustment_02

Pump speed

r/min

1300

Advance angle

deg.

1.5

1

2

Timer adjustment_03

Pump speed

r/min

1430

Advance angle

deg.

4.5

4.2

4.8

Remarks

Finish

Finish

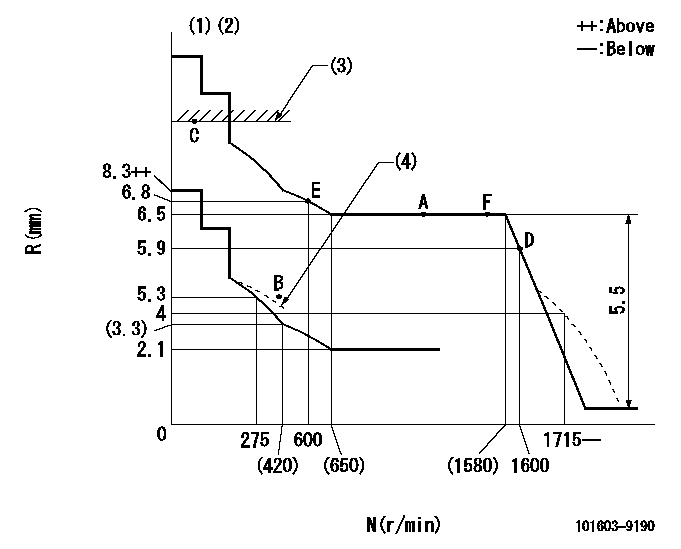

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)RACK LIMIT

(4)Damper spring setting: DL

----------

RT=0.8 TH=1.5mm DL=6-0.2mm

----------

----------

RT=0.8 TH=1.5mm DL=6-0.2mm

----------

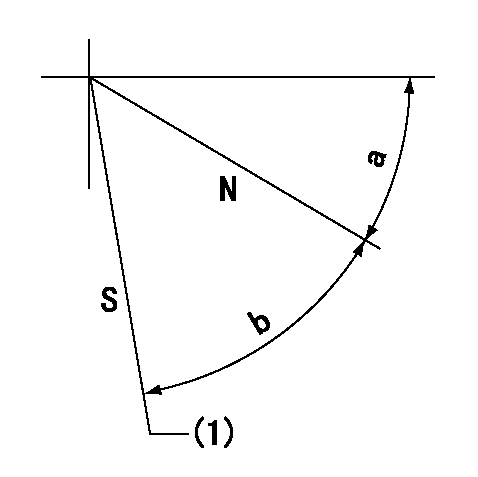

Speed control lever angle

F:Full speed

----------

----------

a=21deg+-5deg

----------

----------

a=21deg+-5deg

0000000901

F:Full load

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt setting

----------

aa=65mm

----------

a=23deg+-3deg b=2deg+-5deg

----------

aa=65mm

----------

a=23deg+-3deg b=2deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa or less

----------

aa=2.5mm

----------

a=35deg+-5deg b=50deg+-5deg

----------

aa=2.5mm

----------

a=35deg+-5deg b=50deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(60deg)

----------

----------

a=(60deg)

Information:

(Diagnosis With Chassis Dynamometer)

1. Preparation of vehicle for fuel consumption test (consult dynamometer manufacturer's operating instructions for specific details on correct operation). Always perform the Primary Engine Test procedure before vehicle is installed on chassis dynamometer.a. Place vehicle on the chassis dynamometer. Tie the vehicle in a way that will not add any load to the drive wheels. Do not pull wheels down into dynamometer drive rolls.Check the radiator coolant level, crankcase oil level, tire pressure, tire condition, remove rocks from the tire tread and connect exhaust system.

Recapped tires should be run on a chassis dynamometer only at the customer's own risk.

b. The maximum acceptable fuel rate must be calculated for the customer's engine by use of the formula that follows: Find the rated brake specific fuel consumption (lb-bhp/hr) from the Fuel Setting And Related Information Fiche and add 0.25 mm (.010 in) manufacturing tolerance. Multiply this value by the advertised engine horsepower (plus 3% manufactures tolerance) and divide by the density of the fuel (lbs/gal).c. Calculate the allowable limitt that the customer can expect from his engine and present these figures to him. Caterpillar engines are rated with the conditions that follow: Barometric pressure = 747 mm (29.4 in) of mercuryInlet air temperature = 29°C (85°F) at air cleaner inletFuel gravity = API gravity of 35 at 16°C (60°F)Measure and record these variables.2. Operate vehicle at 60% of rated speed with moderate load until oil and coolant temperatures reach their normal range for operation.

If there is a heavy vibration, drive shaft whip, tire bounce, etc., do not continue with dynamometer test until cause of the problem is corrected. Engines that have had new internal parts installed should be operated on a run-in schedule before operation at full load.

Put transmission in direct gear and the differential in the highest speed ratio. Operate vehicle at maximum engine speed and increase chassis dynamometer load until a speed of 50 rpm less than rated speed is reached (continuity light should be on). Maintain this speed for one minute and record the engine speed, wheel horsepower and fuel rate.3. If the fuel rate and the wheel horsepower are both acceptable, then the engine is not the cause of the complaint, or the complaint is not valid. Refer to section Problem With Vehicle Or Vehicle Operation.4. If the wheel horsepower is low, regardless of how the fuel rate measures, refer to the Low Power Troubleshooting Chart. The low power problem must be corrected first.5. If the fuel rate and wheel horsepower are both too high, check the set point (balance point) of the engine (speed at which the load stop pin just touches the torque spring or stop bar). At this point the continuity light should flicker (go off and on dimly).If the set point (balance point) is high, the high idle will have to be decreased to lower the set point (balance point) to the correct rpm (point at which the continuity light just comes on). If the set point (balance

1. Preparation of vehicle for fuel consumption test (consult dynamometer manufacturer's operating instructions for specific details on correct operation). Always perform the Primary Engine Test procedure before vehicle is installed on chassis dynamometer.a. Place vehicle on the chassis dynamometer. Tie the vehicle in a way that will not add any load to the drive wheels. Do not pull wheels down into dynamometer drive rolls.Check the radiator coolant level, crankcase oil level, tire pressure, tire condition, remove rocks from the tire tread and connect exhaust system.

Recapped tires should be run on a chassis dynamometer only at the customer's own risk.

b. The maximum acceptable fuel rate must be calculated for the customer's engine by use of the formula that follows: Find the rated brake specific fuel consumption (lb-bhp/hr) from the Fuel Setting And Related Information Fiche and add 0.25 mm (.010 in) manufacturing tolerance. Multiply this value by the advertised engine horsepower (plus 3% manufactures tolerance) and divide by the density of the fuel (lbs/gal).c. Calculate the allowable limitt that the customer can expect from his engine and present these figures to him. Caterpillar engines are rated with the conditions that follow: Barometric pressure = 747 mm (29.4 in) of mercuryInlet air temperature = 29°C (85°F) at air cleaner inletFuel gravity = API gravity of 35 at 16°C (60°F)Measure and record these variables.2. Operate vehicle at 60% of rated speed with moderate load until oil and coolant temperatures reach their normal range for operation.

If there is a heavy vibration, drive shaft whip, tire bounce, etc., do not continue with dynamometer test until cause of the problem is corrected. Engines that have had new internal parts installed should be operated on a run-in schedule before operation at full load.

Put transmission in direct gear and the differential in the highest speed ratio. Operate vehicle at maximum engine speed and increase chassis dynamometer load until a speed of 50 rpm less than rated speed is reached (continuity light should be on). Maintain this speed for one minute and record the engine speed, wheel horsepower and fuel rate.3. If the fuel rate and the wheel horsepower are both acceptable, then the engine is not the cause of the complaint, or the complaint is not valid. Refer to section Problem With Vehicle Or Vehicle Operation.4. If the wheel horsepower is low, regardless of how the fuel rate measures, refer to the Low Power Troubleshooting Chart. The low power problem must be corrected first.5. If the fuel rate and wheel horsepower are both too high, check the set point (balance point) of the engine (speed at which the load stop pin just touches the torque spring or stop bar). At this point the continuity light should flicker (go off and on dimly).If the set point (balance point) is high, the high idle will have to be decreased to lower the set point (balance point) to the correct rpm (point at which the continuity light just comes on). If the set point (balance

Have questions with 101603-9190?

Group cross 101603-9190 ZEXEL

Dpico

Nissan-Diesel

Yanmar

Nissan-Diesel

Dpico

Hyundai

Dpico

101603-9190

INJECTION-PUMP ASSEMBLY

KH

KH