Information injection-pump assembly

ZEXEL

101603-9180

1016039180

Rating:

Service parts 101603-9180 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Cross reference number

ZEXEL

101603-9180

1016039180

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5120

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.5

4.45

4.55

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

9.9

Pump speed

r/min

950

950

950

Average injection quantity

mm3/st.

107.8

105.8

109.8

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

8+-0.5

Pump speed

r/min

275

275

275

Average injection quantity

mm3/st.

17.2

15.2

19.2

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

145

125

165

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

950

Advance angle

deg.

0.5

Timer adjustment_02

Pump speed

r/min

-

Advance angle

deg.

4.5

4.5

4.5

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

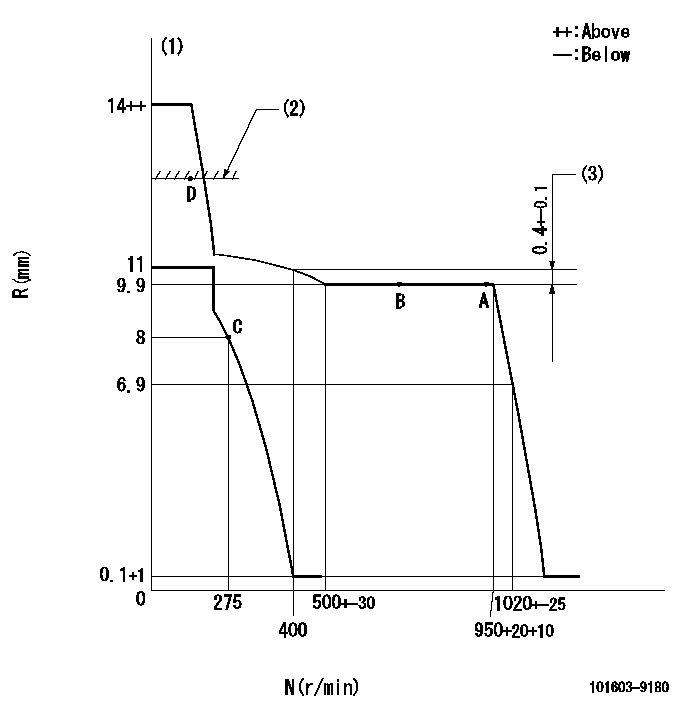

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT

(3)Rack difference between N = N1 and N = N2

----------

K=14 N1=950r/min N2=400r/min

----------

----------

K=14 N1=950r/min N2=400r/min

----------

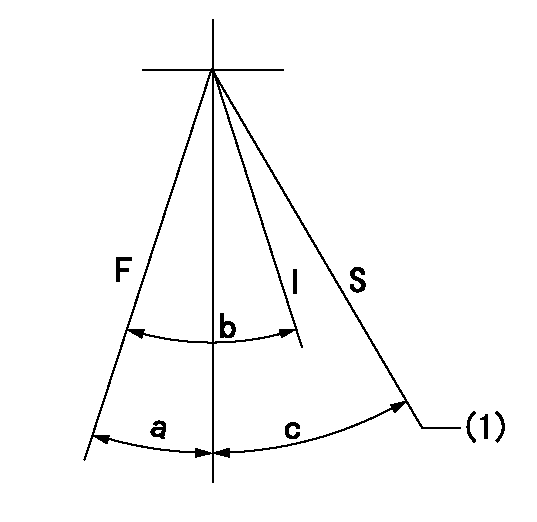

Speed control lever angle

F:Full speed

I:Idle

S:Stop

(1)Rack position = aa

----------

aa=(0.5)mm

----------

a=3deg+-5deg b=29deg+-5deg c=35deg+-3deg

----------

aa=(0.5)mm

----------

a=3deg+-5deg b=29deg+-5deg c=35deg+-3deg

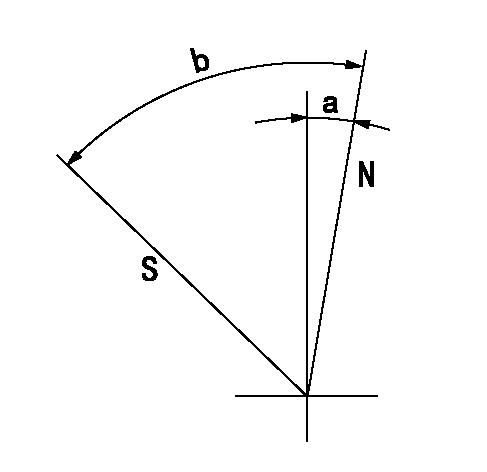

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=2.5deg+-5deg b=53deg+-5deg

----------

----------

a=2.5deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(7deg)

----------

----------

a=(7deg)

Information:

2. Put transmission in direct gear and the differential in the highest speed ratio. Operate vehicle at maximum engine speed and increase chassis dynamometer load until a speed of 50 rpm less than rated speed is reached (continuity light should be on). Maintain this speed for one minute and record the engine speed and wheel horsepower. If horsepower is low and poor maintenance is suspected, remove air cleaner and check horsepower again to see if a plugged air cleaner could be the problem.3a. If the wheel horsepower is correct, find the set point (balance point) of the engine (speed at which the load stop pin just touches the torque spring or stop bar). At this point the continuity light should flicker (go off and on dimly).If the set point (balance point) is correct, then the low power complaint cannot be validated. No further test or repairs are necessary.If the set point (balance point) is low, see Procedure No. 4.3b. If the wheel horsepower is below the correct value, find the set point (balance point) of the engine (speed at which the load stop pin just touches the torque spring or stop bar). At this point the continuity light should flicker (go off and on dimly).If the set point (balance point) is correct, see Procedure No. 5.If the set point (balance point) is low, see Procedure No. 4.4. If the set point (balance point) is low, the high idle will have to be increased to raise the set point (balance point) to the correct rpm (the point at which the continuity light just comes on). If the set point (balance point) is still low and high idle has been adjusted to maximum, disengage clutch while maximum throttle position is maintained. Now observe high idle rpm and, if lower than previously adjusted, check frame-to-engine-mount. A damaged or loose engine mount may put the linkage in a bind and prevent maximum governor position at load conditions.5. If the set point (balance point) was correct and the wheel horsepower was low, install the 1U5470 Engine Pressure Group and do the wheel horsepower test again as shown in Procedure No 2.At full load rpm, measure the boost and the fuel pressure. See Fuel Setting and Related Information Fiche to find the correct boost pressure for a particular engine (since the engine is in vehicle, be sure to make reference to the General Notes in the Fuel Setting and Related Information Fiche to determine the correct boost pressure with air cleaner and muffler installed). If boost is low, check connections ahead of turbine side of turbocharger for exhaust leaks and connections after compressor side of turbocharger for inlet air leaks.6. Check the air inlet restriction and exhaust back pressure.Air flow through the air cleaner and piping must not have a vacuum restriction (negative pressure difference between atmospheric air and air that has gone through air cleaner) of more than 635 mm (25 in) of water. Back pressure from the exhaust (pressure difference measurement between