Information injection-pump assembly

ZEXEL

101603-9120

1016039120

NISSAN-DIESEL

16801Z5500

16801z5500

Rating:

Cross reference number

ZEXEL

101603-9120

1016039120

NISSAN-DIESEL

16801Z5500

16801z5500

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

RED3 control unit part number

407910-2

470

RED3 rack sensor specifications

mm

15

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.4

3.35

3.45

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Rack position

(11.2)

Vist

V

1.75

1.75

1.75

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

65.7

64.7

66.7

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Injection quantity adjustment_02

Rack position

(8.2)

Vist

V

2.4

2.3

2.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

9.5

7.7

11.3

Max. variation between cylinders

%

0

-10

10

Test data Ex:

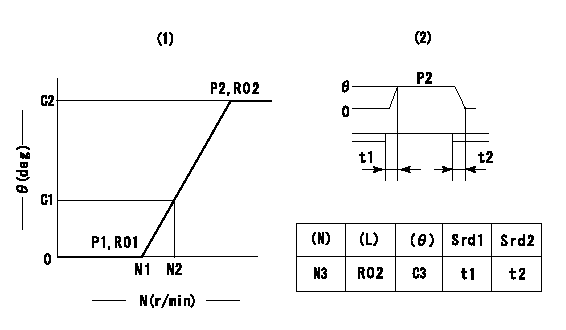

Governor adjustment

(1)Adjusting range

(2)Step response time

(N): Speed of the pump

(L): Load

(theta) Advance angle

(Srd1) Step response time 1

(Srd2) Step response time 2

1. Adjusting conditions for the variable timer

(1)Adjust the clearance between the pickup and the protrusion to L.

----------

L=1.5+-0.2mm N3=800r/min C3=(6.5deg) t1=2--sec. t2=2--sec.

----------

N1=1200++r/min N2=1400r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=2.5--deg C2=6.5+-0.4deg R01=0/4load R02=4/4load

----------

L=1.5+-0.2mm N3=800r/min C3=(6.5deg) t1=2--sec. t2=2--sec.

----------

N1=1200++r/min N2=1400r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=2.5--deg C2=6.5+-0.4deg R01=0/4load R02=4/4load

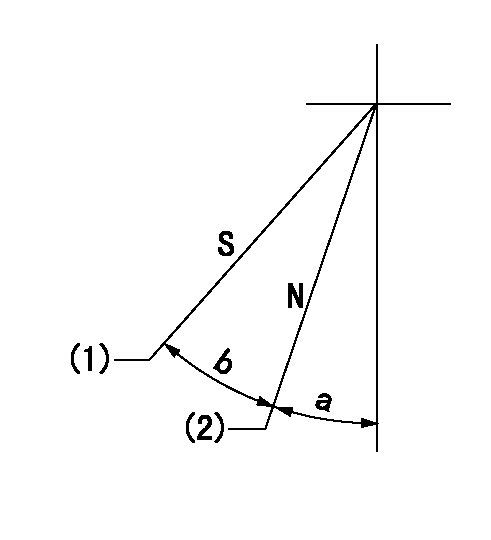

Speed control lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

(2)Rack position bb

----------

aa=1mm bb=16mm

----------

a=30deg+-5deg b=29deg+-5deg

----------

aa=1mm bb=16mm

----------

a=30deg+-5deg b=29deg+-5deg

0000000901

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(60deg)

----------

----------

a=(60deg)

0000001701

(Rs) rack sensor specifications

(C/U) control unit part number

(V) Rack sensor output voltage

(R) Rack position (mm)

1. Confirming governor output characteristics (rack 15 mm, span 6 mm)

(1)When the output voltages of the rack sensor are V1 and V2, check that the rack positions R1 and R2 in the table above are satisfied.

----------

----------

----------

----------

Information:

(1) 9N5496 Spring for valves (outer): Length under test force ... 45.47 mm (1.790 in)Test force ... 185.0 18.0 N (41.6 4 lb)Use again minimum load at length under test force ... 166 N (37.3 lb)Length of spring at valve open position ... 30.23 mm (1.190 in)Use again minimum load at valve open position ... 600 N (135 lb)Free length after test ... 51.77 mm (2.038 in)Outside diameter ... 39.62 mm (1.560 in)Spring must not be bent more than ... 1.80 mm (.071 in)(1) 9N5495 Spring for valves (inner): Length under test force ... 42.47 mm (1.672 in)Test force ... 91.2 9.0 N (20.5 2 lb)Use again minimum load at length under test force ... 81.9 N (18.4 lb)Length of spring at valve open position ... 27.23 mm (1.072 in)Use again minimum load at valve open position ... 295 N (66.3 lb)Free length after test ... 48.77 mm (1.920 in)Outside diameter ... 26.67 mm (1.050 in)Spring must not be bent more than ... 1.70 mm (.067 in)(2) Distance from the end of the valve to the valve spring spacer seat ... 52.40 0.38 mm (2.063 .015 in)(3) Diameter of valve stem: 7C362 and 9L7682 Intake Valve ... 9.462 0.013 mm (.3725 .0005 in)Use again minimum diameter of the valve stem ... 9.42 mm (.371 in)9L7683 and 9N5125 Exhaust Valve (tapered stem):Head end of valve stem ... 9.411 0.013 mm (.3705 .0005 in)Use again minimum diameter of the head end of valve stem ... 9.37 mm (.369 in)Lock end of valve stem ... 9.436 0.013 mm (.3715 .0005 in)Use again minimum diameter of the lock end of valve stem ... 9.408 mm (.3704 in)Bore in the valve guides (intake and exhaust) ... 9.512 0.013 mm (.3745 .0005 in)Maximum permissible bore in the valve guides (worn): Measure 19.0 mm (.75 in) deep in valve guide bore from both ends of the valve guide ... 9.550 mm (.3760 in)(4) Angle of valve face: Intake valve ... 30° 15'Exhaust valve ... 45° 15'(5) Diameter of valve head (intake valve) ... 53.19 0.13 mm (2.094 .005 in) Diameter of valve head (exhaust valve) ... 45.82 0.13 mm (1.804 .005 in)(6) Thickness of valve lip: Intake valve ... 2.31 mm (.091 in)Use again minimum valve lip thickness ... 1.78 mm (.070 in)Exhaust valve ... 1.60 mm (.063 in)Use again minimum valve lip thickness ... 1.27 mm (.050 in)