Information injection-pump assembly

ZEXEL

101603-8652

1016038652

ISUZU

8943959793

8943959793

Rating:

Cross reference number

ZEXEL

101603-8652

1016038652

ISUZU

8943959793

8943959793

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-4920

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.7

4.65

4.75

Rack position

After adjusting injection quantity. R=A

After adjusting injection quantity. R=A

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

12.6

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

82

80.4

83.6

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

275

275

275

Average injection quantity

mm3/st.

8.5

7.2

9.8

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(12.6)

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

82

81

83

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1(12.6)

Pump speed

r/min

1425

1425

1425

Average injection quantity

mm3/st.

88.5

85.3

91.7

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1-0.2

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

72.5

69.3

75.7

Fixing the lever

*

Timer adjustment

Pump speed

r/min

1300--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1250

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1400

Advance angle

deg.

4.5

4

5

Remarks

Finish

Finish

Test data Ex:

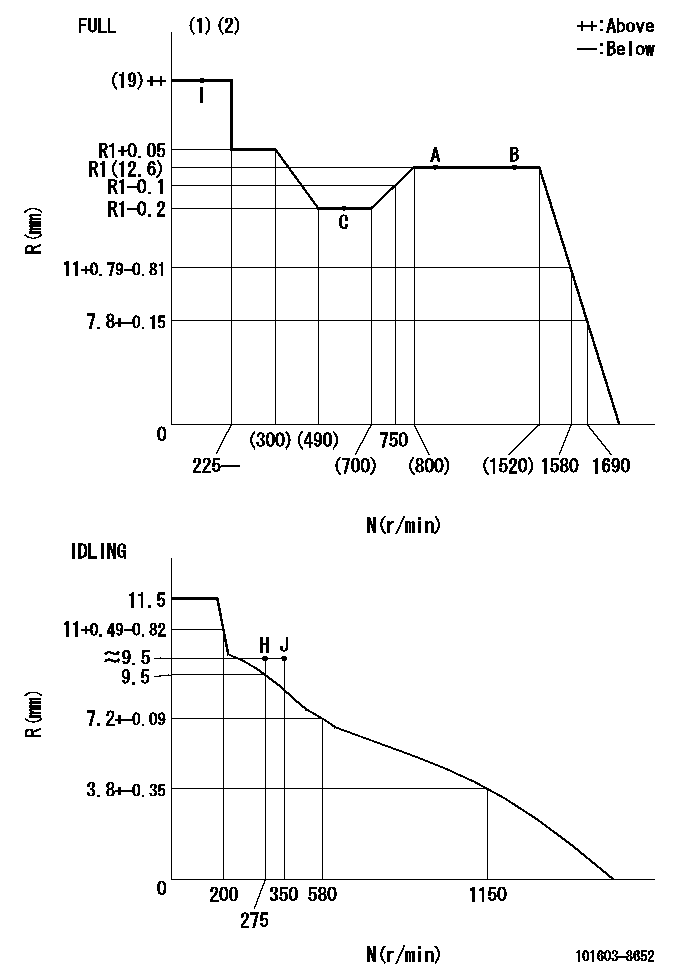

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

----------

T1=K49

----------

----------

T1=K49

----------

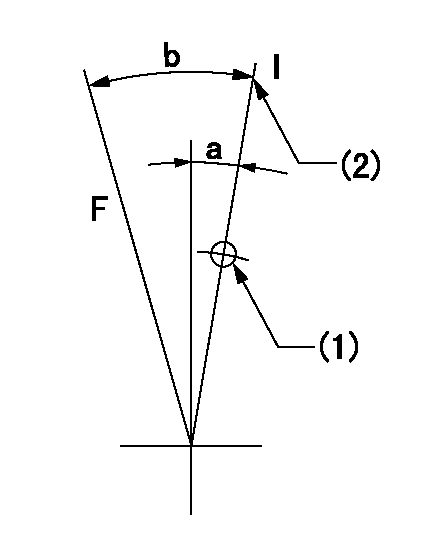

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=35mm

----------

a=14deg+-5deg b=40deg+-3deg

----------

aa=35mm

----------

a=14deg+-5deg b=40deg+-3deg

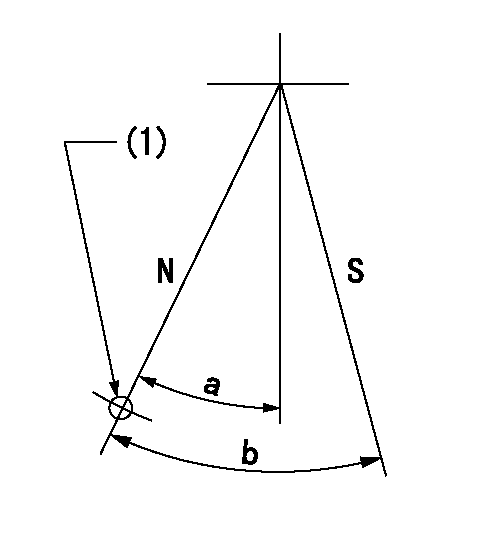

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the pin at R = aa

----------

aa=46.5mm

----------

a=34.5deg+-5deg b=40deg+-5deg

----------

aa=46.5mm

----------

a=34.5deg+-5deg b=40deg+-5deg

0000001501 I/P WITH LOAD PLUNGER ADJ

Plunger assembly number: PL (stamping: ST)

1. Adjustment procedures

(1)Insert the pre-stroke adjusting shims L1 for each cylinder.

(2)Adjust injection quantity.(max. var. bet. cyl. idling a1, full a2)

(3)At basic point A, adjust so that the pre-stroke is L2.

(4)Reconfirm the injection quantity.

----------

PL=131153-9020 ST=A769 L1=1mm L2=4.7+-0.05mm a1=+-14% a2=+-2.5%

----------

----------

PL=131153-9020 ST=A769 L1=1mm L2=4.7+-0.05mm a1=+-14% a2=+-2.5%

----------

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)At rack position = bb

----------

aa=6deg bb=R1(12.6)mm

----------

a=(150deg)

----------

aa=6deg bb=R1(12.6)mm

----------

a=(150deg)

Information:

1. Remove bolt (1) from the alternator and bracket. 2. Remove the two bolts that hold bracket (3) to the timing gear cover.3. Disconnect water line (2) from the air compressor. 4. Remove bolts (4) and (5) that hold the cylinder head to the cylinder block. 5. Fasten a hoist and remove cylinder head (6). The weight is approximately 300 lb. (135 kg).

Do not put the cylinder head down on a flat surface. This can cause damage to the fuel injection valves.

6. Remove the seals from the spacer plate.Install Cylinder Head Assembly

Be sure a new gasket has been installed between the spacer plate and the cylinder block. See REMOVE AND INSTALL SPACER PLATE. 1. Thoroughly clean the spacer plate and the bottom surface of the cylinder head. Install a new head gasket and new seals (1). Later model engines have two O-ring seals on top and bottom of the spacer plate. 2. Fasten a hoist and put cylinder head (2) in position on the cylinder block. 3. Put clean engine oil on the threads of the cylinder head bolts. Install the cylinder head bolts and washers. Tighten the bolts in sequence shown in illustration A87019x1: a) Tighten bolts 1 through 20 in number sequence to a torque of 200 20 lb.ft. (270 25 N m).b) Tighten bolts 1 through 20 in number sequence to a torque of 330 15 lb.ft. (450 20 N m).c) Tighten bolts 1 through 20 in number sequence to a torque of 330 15 lb.ft. (450 20 N m) by hand.d) Install rocker shafts and push rods. See INSTALL ROCKER SHAFTS AND PUSH RODS.e) Tighten bolts 21 through 26 in number sequence to a torque of 200 20 lb.ft. (270 25 N m).f) Tighten bolts 21 through 26 in number sequence to a torque of 330 15 lb.ft. (450 20 N m).g) Tighten bolts 21 through 26 in number sequence to a torque of 330 15 lb.ft. (450 20 N m) by hand.h) Tighten the 3/8" bolts to a torque of 32 5 lb. ft. (43 7 N m). If the studs for the exhaust manifold were removed, install new studs and tighten to 20 3 lb.ft. (25 4 N m).4. Make a adjustment to the valves to have a clearance of .015 (0.38 mm) for intake and .030 (0.76 mm) for exhaust. Install the valve cover bases and the inner fuel lines. Tighten the locknuts for the valve adjustment screws to a torque of 22 3 lb.ft. (28 4 N m).5. Install the valve cover bases and the inner fuel lines. See INSTALL ROCKER SHAFT AND PUSH RODS.6. Install the valve covers. See INSTALL VALVE COVERS. 7. Connect water line (3) to the air compressor. 8. Install bolt (4) for the alternator.end by:a) install exhaust manifoldb) install fuel injection linesc) install inlet manifoldd) install water temperature regulator

Do not put the cylinder head down on a flat surface. This can cause damage to the fuel injection valves.

6. Remove the seals from the spacer plate.Install Cylinder Head Assembly

Be sure a new gasket has been installed between the spacer plate and the cylinder block. See REMOVE AND INSTALL SPACER PLATE. 1. Thoroughly clean the spacer plate and the bottom surface of the cylinder head. Install a new head gasket and new seals (1). Later model engines have two O-ring seals on top and bottom of the spacer plate. 2. Fasten a hoist and put cylinder head (2) in position on the cylinder block. 3. Put clean engine oil on the threads of the cylinder head bolts. Install the cylinder head bolts and washers. Tighten the bolts in sequence shown in illustration A87019x1: a) Tighten bolts 1 through 20 in number sequence to a torque of 200 20 lb.ft. (270 25 N m).b) Tighten bolts 1 through 20 in number sequence to a torque of 330 15 lb.ft. (450 20 N m).c) Tighten bolts 1 through 20 in number sequence to a torque of 330 15 lb.ft. (450 20 N m) by hand.d) Install rocker shafts and push rods. See INSTALL ROCKER SHAFTS AND PUSH RODS.e) Tighten bolts 21 through 26 in number sequence to a torque of 200 20 lb.ft. (270 25 N m).f) Tighten bolts 21 through 26 in number sequence to a torque of 330 15 lb.ft. (450 20 N m).g) Tighten bolts 21 through 26 in number sequence to a torque of 330 15 lb.ft. (450 20 N m) by hand.h) Tighten the 3/8" bolts to a torque of 32 5 lb. ft. (43 7 N m). If the studs for the exhaust manifold were removed, install new studs and tighten to 20 3 lb.ft. (25 4 N m).4. Make a adjustment to the valves to have a clearance of .015 (0.38 mm) for intake and .030 (0.76 mm) for exhaust. Install the valve cover bases and the inner fuel lines. Tighten the locknuts for the valve adjustment screws to a torque of 22 3 lb.ft. (28 4 N m).5. Install the valve cover bases and the inner fuel lines. See INSTALL ROCKER SHAFT AND PUSH RODS.6. Install the valve covers. See INSTALL VALVE COVERS. 7. Connect water line (3) to the air compressor. 8. Install bolt (4) for the alternator.end by:a) install exhaust manifoldb) install fuel injection linesc) install inlet manifoldd) install water temperature regulator