Information injection-pump assembly

BOSCH

9 400 615 237

9400615237

ZEXEL

101603-8032

1016038032

ISUZU

8943937153

8943937153

Rating:

Include in #1:

101401-4131

as _

Cross reference number

BOSCH

9 400 615 237

9400615237

ZEXEL

101603-8032

1016038032

ISUZU

8943937153

8943937153

Zexel num

Bosch num

Firm num

Name

101603-8032

9 400 615 237

8943937153 ISUZU

INJECTION-PUMP ASSEMBLY

6HE1-S K

6HE1-S K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-4920

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

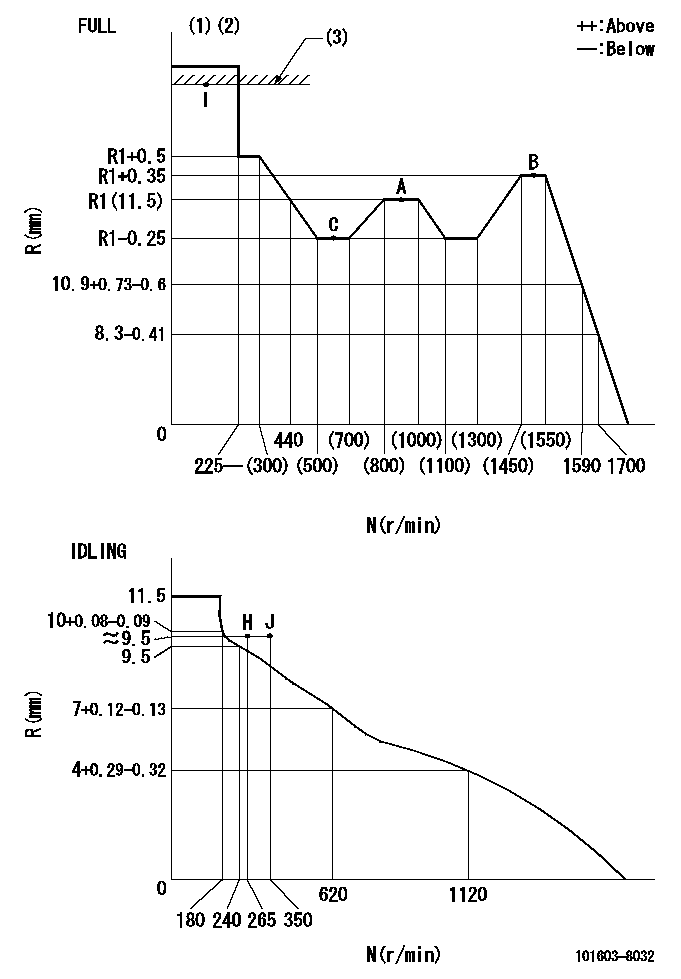

Injection quantity adjustment

Adjusting point

-

Rack position

11.5

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

77.7

76.1

79.3

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

265

265

265

Average injection quantity

mm3/st.

8.8

7.5

10.1

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.5)

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

77.7

76.7

78.7

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.35

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

94.6

90.6

98.6

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1-0.25

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

60.9

57.7

64.1

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

I

Rack position

-

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

96

96

104

Fixing the lever

*

Timer adjustment

Pump speed

r/min

1300--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1250

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1500

Advance angle

deg.

4

3.5

4.5

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

----------

T1=H33

----------

----------

T1=H33

----------

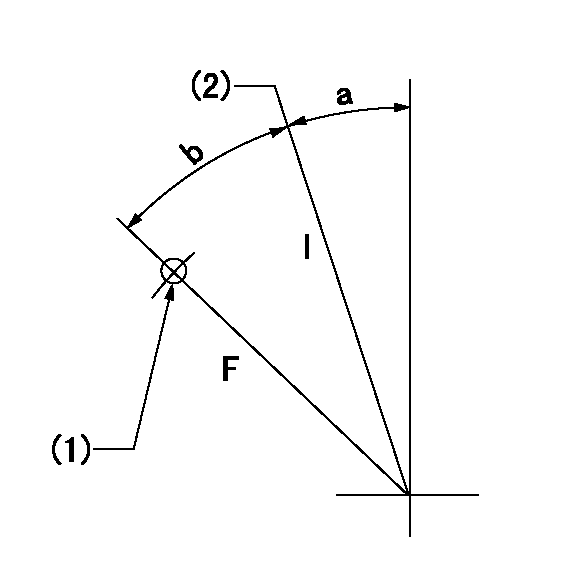

Speed control lever angle

F:Full speed

I:Idle

(1)Use the pin at R = aa

(2)Stopper bolt setting

----------

aa=35mm

----------

a=11deg+-5deg b=36deg+-3deg

----------

aa=35mm

----------

a=11deg+-5deg b=36deg+-3deg

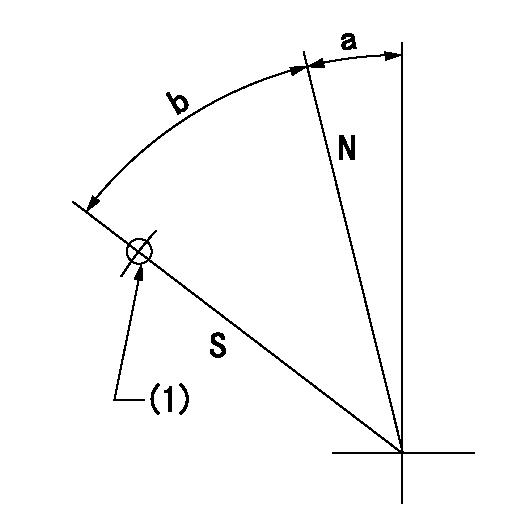

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the pin at R = aa

----------

aa=45mm

----------

a=12.5deg+-5deg b=40deg+-5deg

----------

aa=45mm

----------

a=12.5deg+-5deg b=40deg+-5deg

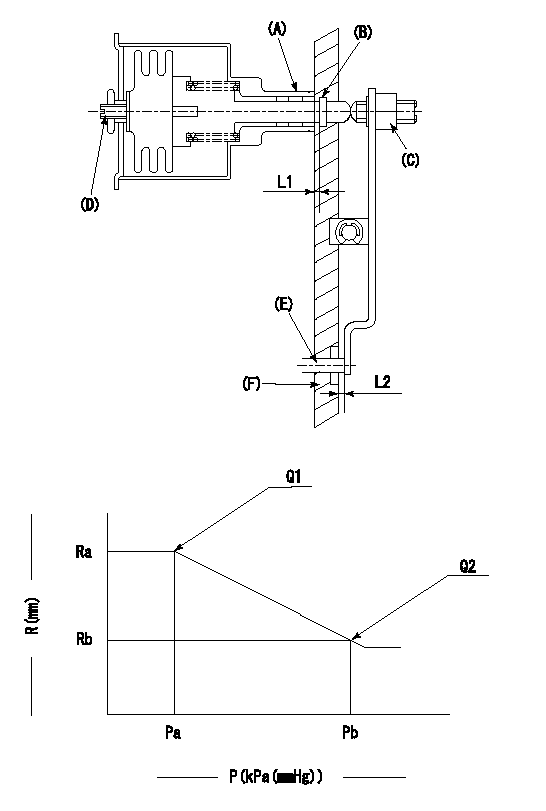

0000001501 ACS

(A) Housing

(B) Snap ring

(C) adjusting screw

(D) Set screw

(E): Push rod

(F) Spacer

1. Adjustment of the aneroid compensator

(1)Adjust with the (D) set screw so that the clearance between the (A) housing and (B) snap ring is L1.

(2)Select the push rod (E) so that the distance from the end surface of the (F) spacer becomes L2.

(3)(C) Turn the screw to adjust the beginning of aneroid compensator operation.

2. Adjustment when mounting the governor.

(1)Set the speed of the pump to N1 r/min and fix the control lever at the full set position.

(2)Adjust using screw C to obtain the performance shown in the graph above.

(3)After final adjustment, confirm that the gap between housing (A) and snapring (B) is L3.

----------

N1=900r/min L1=1.4~1.7mm L2=0.5+-0.5mm L3=(0.1~0.5)mm

----------

Ra=R1(11.5)mm Rb=(R1-0.5)mm Pa=89.8+-2.7kPa(674+-20mmHg) Pb=70.1+-0.7kPa(526+-5mmHg) Q1=77.7+-1cm3/1000st Q2=58.1+-1.6cm3/1000st

----------

N1=900r/min L1=1.4~1.7mm L2=0.5+-0.5mm L3=(0.1~0.5)mm

----------

Ra=R1(11.5)mm Rb=(R1-0.5)mm Pa=89.8+-2.7kPa(674+-20mmHg) Pb=70.1+-0.7kPa(526+-5mmHg) Q1=77.7+-1cm3/1000st Q2=58.1+-1.6cm3/1000st

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=14deg

----------

a=(150deg)

----------

aa=14deg

----------

a=(150deg)

Information:

2. Remove bolts (1) that hold cover (2) in position.3. Remove cover (2). 4. Remove bolts (3), retainer (4) and automatic timing advance (5).Install Automatic Timing Advance

1. Put automatic timing advance (1) in position in the housing. 2. Install retainer (3) and bolts (2).3. Check fuel injection pump timing with tool (A). See CAMSHAFT TIMING FOR THE FUEL INJECTION PUMP in TESTING AND ADJUSTING.4. Tighten bolts (2) evenly to a torque of 20 lb.ft. (25 N m). Remove tool (A).5. Tighten bolts (2) to a torque of 100 5 lb.ft. (135 7 N m).6. Turn the crankshaft two complete turns and check the camshaft timing again. 7. Install cover (4) and the bolts.Disassemble Automatic Timing Advance

start by:a) remove automatic timing advance 1. Remove ring (1) and gear assembly (2) from the flange assembly.2. Remove the slides from the weights. 3. Remove springs (4) and weights (3) from the flange assembly.Assemble Automatic Timing Advance

1. Put weights (2) in position in flange assembly (1) as shown.2. Install springs (3) in flange assembly (1). 3. If pistons (6) were removed from the gear assembly because of wear, use new parts for replacement. Install new pistons (6) until they are .435 .005 in. (11.05 .13 mm) above the inside surface of gear assembly (4). Move the metal (peen) on the outside surface of gear assembly (4) in four places around each piston to hold them in position.4. Use 1P808 General Purpose Lubricant to hold slides (5) in position on gear assembly (4).5. Install gear assembly (4) on flange assembly (1). Make sure slides (5) fit in grooves of the weights.6. Install the ring that holds gear assembly (4) to the flange assembly.end by:a) install automatic timing advance

1. Put automatic timing advance (1) in position in the housing. 2. Install retainer (3) and bolts (2).3. Check fuel injection pump timing with tool (A). See CAMSHAFT TIMING FOR THE FUEL INJECTION PUMP in TESTING AND ADJUSTING.4. Tighten bolts (2) evenly to a torque of 20 lb.ft. (25 N m). Remove tool (A).5. Tighten bolts (2) to a torque of 100 5 lb.ft. (135 7 N m).6. Turn the crankshaft two complete turns and check the camshaft timing again. 7. Install cover (4) and the bolts.Disassemble Automatic Timing Advance

start by:a) remove automatic timing advance 1. Remove ring (1) and gear assembly (2) from the flange assembly.2. Remove the slides from the weights. 3. Remove springs (4) and weights (3) from the flange assembly.Assemble Automatic Timing Advance

1. Put weights (2) in position in flange assembly (1) as shown.2. Install springs (3) in flange assembly (1). 3. If pistons (6) were removed from the gear assembly because of wear, use new parts for replacement. Install new pistons (6) until they are .435 .005 in. (11.05 .13 mm) above the inside surface of gear assembly (4). Move the metal (peen) on the outside surface of gear assembly (4) in four places around each piston to hold them in position.4. Use 1P808 General Purpose Lubricant to hold slides (5) in position on gear assembly (4).5. Install gear assembly (4) on flange assembly (1). Make sure slides (5) fit in grooves of the weights.6. Install the ring that holds gear assembly (4) to the flange assembly.end by:a) install automatic timing advance

Have questions with 101603-8032?

Group cross 101603-8032 ZEXEL

Isuzu

101603-8032

9 400 615 237

8943937153

INJECTION-PUMP ASSEMBLY

6HE1-S

6HE1-S