Information injection-pump assembly

ZEXEL

101603-7830

1016037830

ISUZU

8943934590

8943934590

Rating:

Cross reference number

ZEXEL

101603-7830

1016037830

ISUZU

8943934590

8943934590

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-4920

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

11.5

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

77.7

76.1

79.3

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

265

265

265

Average injection quantity

mm3/st.

8.8

7.5

10.1

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.5)

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

77.7

76.7

78.7

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.2

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

90.7

86.7

94.7

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1-0.2

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

61.8

58.6

65

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

I

Rack position

-

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

96

96

104

Fixing the lever

*

Timer adjustment

Pump speed

r/min

1300--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1250

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1500

Advance angle

deg.

4

3.5

4.5

Remarks

Finish

Finish

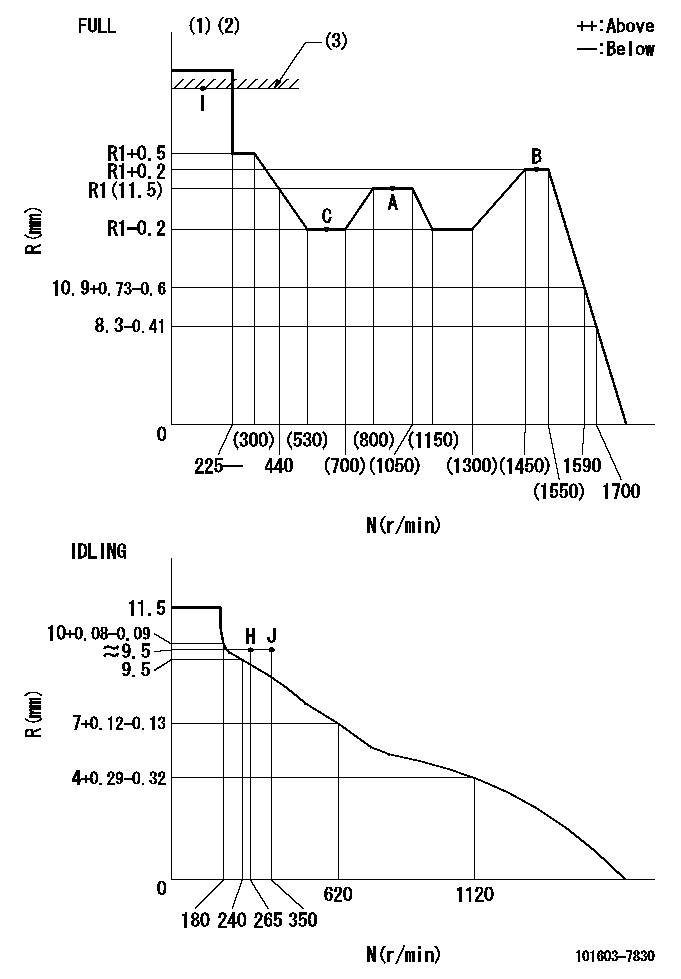

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

----------

T1=G80

----------

----------

T1=G80

----------

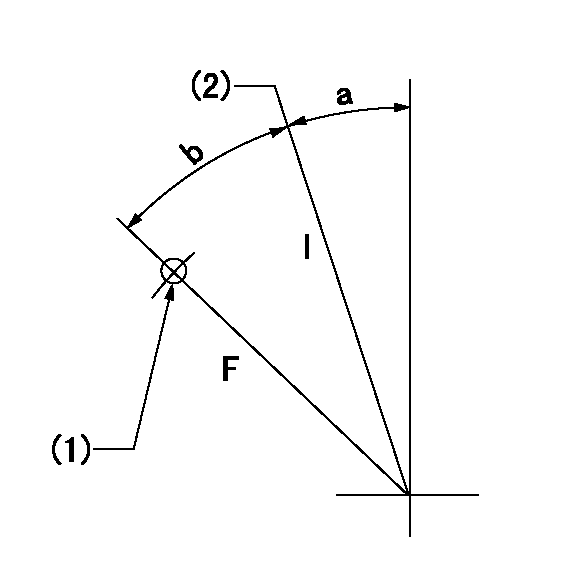

Speed control lever angle

F:Full speed

I:Idle

(1)Use the pin at R = aa

(2)Stopper bolt setting

----------

aa=35mm

----------

a=11deg+-5deg b=36deg+-3deg

----------

aa=35mm

----------

a=11deg+-5deg b=36deg+-3deg

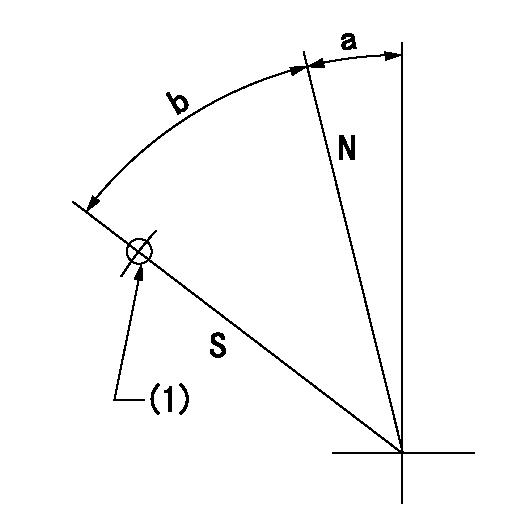

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the pin at R = aa

----------

aa=45mm

----------

a=12.5deg+-5deg b=40deg+-5deg

----------

aa=45mm

----------

a=12.5deg+-5deg b=40deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=14deg

----------

a=(150deg)

----------

aa=14deg

----------

a=(150deg)

Information:

This Program must be administered assoon as possible. When reporting the repair, use "PI30156" as the Partnumber and "7751" as the Group Number, "56" as the Warranty Claim DescriptionCode and "T" as the SIMS Description Code. Exception: If the repair isdone after failure, use "PI30156" as the Part Number, "7751" as the GroupNumber, "96" as the Warranty Claim Description Code, and "Z" as the SIMSDescription Code. The information supplied in this serviceletter may not be valid after the termination date of this program. Donot perform the work outlined in this Service Letter after the terminationdate without first contacting your Caterpillar product analyst. This Revised Service Letter replacesthe March 24, 2001 Service Letter. Changes were made to Parts Needed, ReworkProcedure, Service Claim Allowances, Owner Notification and Parts Disposition. This Service Letter should not be performedon engines with greater than 7500 miles (>12000 KM) or >150 hours.

COMPLETION DATE

TERMINATION DATE

September 30, 2001 March 31, 2002PROBLEM

Due to a manufacturing error, there is a possibilitythat numerous 1043568 Injector Pushrods missed the heat treating operation.Certain C-10, C-12, 3176C, and 3196 engines will need to have the injectorpushrods checked and possibly replaced. This Service letter should onlybe performed on engines with between 0 to 7500 miles (0 to 12000 kM) or0-150 hours.AFFECTED PRODUCT

Model Identification NumberTRUCK/COMMERCIAL ENGINESC-10 3CS18811 ? 193268YS7628 - 7646C-12 2KS61890 ? 632739SM277 - 3363176C IND 2AW1272 ? 13063196 IND 1DW611 ? 6143176C MAR 6BW498 ? 4993196 MAR 2XR3757 ? 38623176C Machine 3PD168 - 2023196 Machine 5ED216 - 2373176C Machine 7ZR5409 - 55163196 Machine 6AR2595 - 2635MACHINES725 AFX130-131, 142-145, 148-150,174, 177-179730 AGF217-218, 225-228345 AGS480, 562, 564, 566, 571,575, 578, 582-584ALB197APB110-112CFM27665E 6GS632, 634, 637, 639?649, 65275E 1HM310-3126HS647, 64985E 1NM230-2316JS668-669, 67295E 1SM282 ? 2896KS985, 987, 993PARTS NEEDED

AS REQUIRED

1043568 Injector Pushrods(depending on the results of the inspection,0?6 pushrods may be needed for the rework? Only individual pushrods foundto be soft need to be replaced)AS REQUIRED

Injector Group(depending on the results of the pushrodinspection , 0-6 injectors may be needed for the rework? An injector shouldbe replaced only if the pushrod for that particular injector isfound to be soft and if the engine has more than 200 MILES (322KM) or 20 HOURS.)ACTION REQUIRED

Remove the valve covers.

Using a medium to coarse flat file against thecup of the pushrod, stroke the file.

If the push rod is soft you will feel a distinctdrag as the file digs into the material.

If the push rod is hard the file will feel likeit is passing over glass as the file slides across the hard surface.

If you are not certain if a pushrod is soft orhard CALL YOUR TC OR THE CAT PRODUCT ANALYST AT:(800)447-4986.

If a pushrod is soft, remove the rocker arm andreplace the pushrod. Tighten the rocker stand bolts according to the torquevalue found in Service Manual.

IF A PUSHROD IS FOUND TO BE SOFT AND THE ENGINEHAS MORE THAN 200 miles (322 KM) OR 20 hours on it replace onlythe injector that is driven by the soft pushrod. Lubricate the two largero-ring seals with engine oil and install the injectors. Tighten the injectorhold down

COMPLETION DATE

TERMINATION DATE

September 30, 2001 March 31, 2002PROBLEM

Due to a manufacturing error, there is a possibilitythat numerous 1043568 Injector Pushrods missed the heat treating operation.Certain C-10, C-12, 3176C, and 3196 engines will need to have the injectorpushrods checked and possibly replaced. This Service letter should onlybe performed on engines with between 0 to 7500 miles (0 to 12000 kM) or0-150 hours.AFFECTED PRODUCT

Model Identification NumberTRUCK/COMMERCIAL ENGINESC-10 3CS18811 ? 193268YS7628 - 7646C-12 2KS61890 ? 632739SM277 - 3363176C IND 2AW1272 ? 13063196 IND 1DW611 ? 6143176C MAR 6BW498 ? 4993196 MAR 2XR3757 ? 38623176C Machine 3PD168 - 2023196 Machine 5ED216 - 2373176C Machine 7ZR5409 - 55163196 Machine 6AR2595 - 2635MACHINES725 AFX130-131, 142-145, 148-150,174, 177-179730 AGF217-218, 225-228345 AGS480, 562, 564, 566, 571,575, 578, 582-584ALB197APB110-112CFM27665E 6GS632, 634, 637, 639?649, 65275E 1HM310-3126HS647, 64985E 1NM230-2316JS668-669, 67295E 1SM282 ? 2896KS985, 987, 993PARTS NEEDED

AS REQUIRED

1043568 Injector Pushrods(depending on the results of the inspection,0?6 pushrods may be needed for the rework? Only individual pushrods foundto be soft need to be replaced)AS REQUIRED

Injector Group(depending on the results of the pushrodinspection , 0-6 injectors may be needed for the rework? An injector shouldbe replaced only if the pushrod for that particular injector isfound to be soft and if the engine has more than 200 MILES (322KM) or 20 HOURS.)ACTION REQUIRED

Remove the valve covers.

Using a medium to coarse flat file against thecup of the pushrod, stroke the file.

If the push rod is soft you will feel a distinctdrag as the file digs into the material.

If the push rod is hard the file will feel likeit is passing over glass as the file slides across the hard surface.

If you are not certain if a pushrod is soft orhard CALL YOUR TC OR THE CAT PRODUCT ANALYST AT:(800)447-4986.

If a pushrod is soft, remove the rocker arm andreplace the pushrod. Tighten the rocker stand bolts according to the torquevalue found in Service Manual.

IF A PUSHROD IS FOUND TO BE SOFT AND THE ENGINEHAS MORE THAN 200 miles (322 KM) OR 20 hours on it replace onlythe injector that is driven by the soft pushrod. Lubricate the two largero-ring seals with engine oil and install the injectors. Tighten the injectorhold down