Information injection-pump assembly

BOSCH

9 400 615 216

9400615216

ZEXEL

101603-7811

1016037811

ISUZU

1156027861

1156027861

Rating:

Service parts 101603-7811 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

1-15300-266-4

12.

Open Pre:MPa(Kqf/cm2)

18.1{185}

15.

NOZZLE SET

Include in #1:

101603-7811

as INJECTION-PUMP ASSEMBLY

Include in #2:

104741-5325

as _

Cross reference number

BOSCH

9 400 615 216

9400615216

ZEXEL

101603-7811

1016037811

ISUZU

1156027861

1156027861

Zexel num

Bosch num

Firm num

Name

101603-7811

9 400 615 216

1156027861 ISUZU

INJECTION-PUMP ASSEMBLY

6BG1-TC1 K

6BG1-TC1 K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-4920

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.6

3.55

3.65

Rack position

After adjusting injection quantity. R=A

After adjusting injection quantity. R=A

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

13.2

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

95.7

94.1

97.3

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

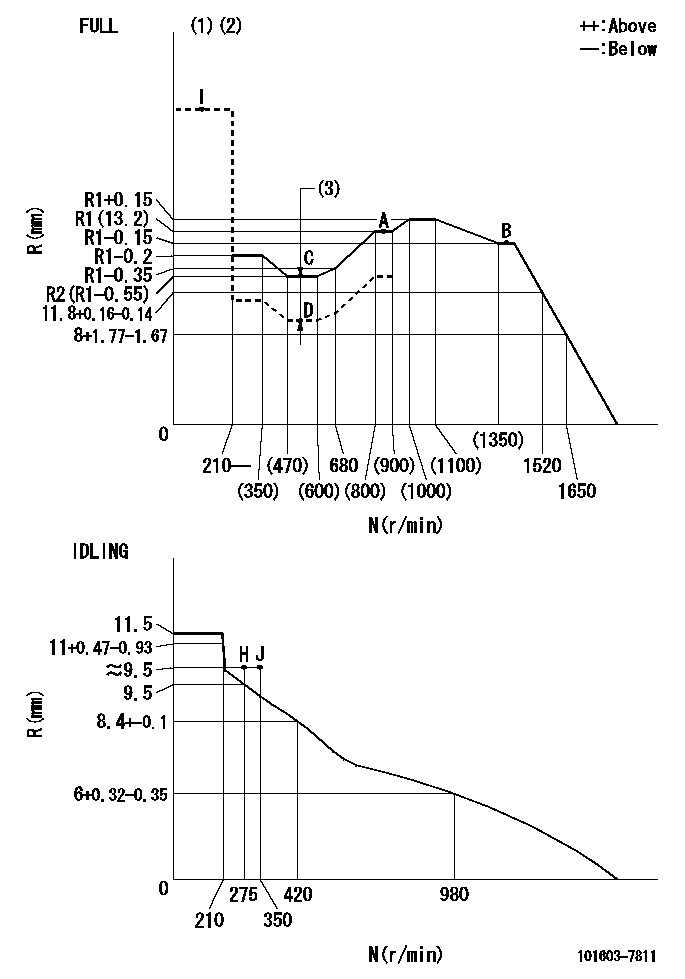

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

275

275

275

Average injection quantity

mm3/st.

8

6.7

9.3

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(13.2)

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

95.7

94.7

96.7

Basic

*

Fixing the lever

*

Boost pressure

kPa

34.7

34.7

Boost pressure

mmHg

260

260

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1-0.15

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

96.7

93.5

99.9

Fixing the lever

*

Boost pressure

kPa

34.7

34.7

Boost pressure

mmHg

260

260

Injection quantity adjustment_05

Adjusting point

C

Rack position

R2(R1-0.

55)

Pump speed

r/min

550

550

550

Average injection quantity

mm3/st.

77

73.8

80.2

Fixing the lever

*

Boost pressure

kPa

34.7

34.7

Boost pressure

mmHg

260

260

Injection quantity adjustment_06

Adjusting point

D

Rack position

R2-1.5

Pump speed

r/min

550

550

550

Average injection quantity

mm3/st.

54

50.8

57.2

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_07

Adjusting point

I

Rack position

-

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

93

93

125

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

550

550

550

Rack position

R2-1.5

Boost pressure

kPa

3.3

3.3

6

Boost pressure

mmHg

25

25

45

Boost compensator adjustment_02

Pump speed

r/min

550

550

550

Rack position

R2(R1-0.

55)

Boost pressure

kPa

21.3

21.3

21.3

Boost pressure

mmHg

160

160

160

Timer adjustment

Pump speed

r/min

(1170)

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1325

Advance angle

deg.

1.5

1

2

Timer adjustment_03

Pump speed

r/min

1400

Advance angle

deg.

2

1.5

2.5

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Boost compensator stroke: BCL

----------

T1=F36 BCL=1.5+-0.1mm

----------

----------

T1=F36 BCL=1.5+-0.1mm

----------

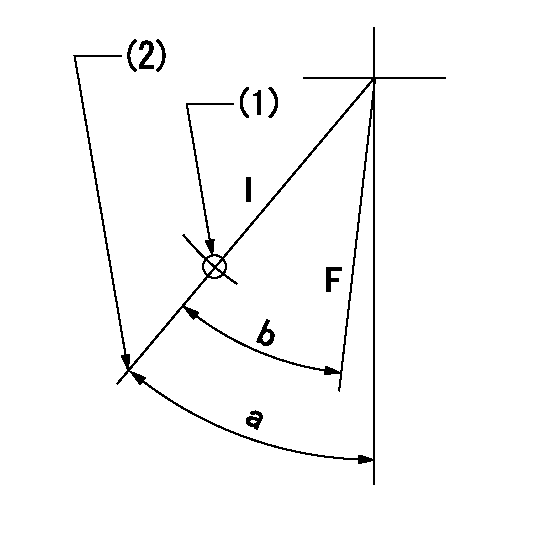

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=35mm

----------

a=39.5deg+-5deg b=(37deg)+-3deg

----------

aa=35mm

----------

a=39.5deg+-5deg b=(37deg)+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=25deg+-5deg b=40deg+-5deg

----------

----------

a=25deg+-5deg b=40deg+-5deg

0000001501 I/P WITH LOAD PLUNGER ADJ

Plunger assembly number: PL (stamping: ST)

1. Adjustment procedures

(1)Insert the pre-stroke adjusting shims L1 for each cylinder.

(2)Adjust injection quantity.(max. var. bet. cyl. idling a1, full a2)

(3)At basic point A, adjust so that the pre-stroke is L2.

(4)Reconfirm the injection quantity.

----------

PL=131153-3720 ST=A716 L1=1mm L2=3.6+-0.05mm a1=+-14% a2=+-2.5%

----------

----------

PL=131153-3720 ST=A716 L1=1mm L2=3.6+-0.05mm a1=+-14% a2=+-2.5%

----------

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=10deg

----------

a=(60deg)

----------

aa=10deg

----------

a=(60deg)

Information:

This Program must be administered as soon as possible. When reporting the repair, use "PI3325" as the Part Number, "7751" as the Group Number, "56" as the Warranty Claim Description Code and "T" as the SIMS Description Code. Exception: If the repair is done after failure, use "PI3325" as the Part Number, "7751" as the Group Number, "96" as the Warranty Claim Description Code, and "Z" as the SIMS Description Code.

Completion Date

February 29, 2000Termination Date

February 29, 2000Problem

Upgrade software needs to be installed on certain 3606, 3608, 3612, and 3616 diesel engines with the Marine Monitoring System (MMS) to become Y2K compatible.

Affected Product

Model & Identification Number

3606 (8RB29, 8RB656-661, 8RB669, 8RB672-673, 8RB680-688, 8RB691-00692, 8RB695-702, 8RB711-00713, 8RB715, 8RB717-718, 8RB721-723)

3608 (6MC535-536, 6MC550, 6MC561-562, 6MC582-586)

3612 (9RC230, 9RC242, 9RC247-253, 9RC256-257, 9RC259-260)

3616 (1PD289-293, 1PD295, 1PD306, 1PD308, 1PD313-336)

Parts Needed

- Dealers will need to obtain the Upgrade Files for this program.- 1 Blank formatted 1.44 MB floppy disk for Winfile Upgrade- 6 Blank formatted 1.44 MB floppy disks for InTouch 5.6B UpgradeAction Required

See the attached procedure.

Owner Notification

U.S. and Canadian owners will receive the attached Owner Notification.

Service Claim Allowances

This is a 1-hour job.

U.S. and Canadian Dealers Only - Eligible dealers may enter a Type 2 SIMS Report.

Parts Disposition

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

MAKE EVERY EFFORT TO COMPLETE THIS PROGRAM AS SOON AS POSSIBLE.

Attach.(1-Owner Notification)(1-Rework Procedure)Copy Of Owner Notification For U.S. And Canadian Owners

Rework Procedure

Windows 3.11 Winfile Upgrade

This upgrade is necessary for Windows 3.11 to correctly date stamp files after the year 2000, The first three steps in the following procedure will be done in the office or shop.

1. Obtain the file. The file can be obtained from the Caterpillar Mailbox, SISWEB, or from the SIS disks that are released monthly. The file part number is 174-8693.2. Unzip the file. The 174-8693.exe file is a self-executing zip file. To Unzip, place the file in a known location on the hard drive. Run the file. At the dialog box type in 'A:\' where it asks for the folder to place unzipped files. Install a blank formatted disk into the A: drive. Select UNZIP or press "ENTER". This will unzip the files to the floppy drive. If your floppy drive is not 'A:' substitute your floppy drive letter for A in the above instuctions.)

3. Label the disk. This disk should be labeled "Winfile.exe Y2K Upgrade". This disk or a copy of this disk can be used to do multiple upgrades. It is not necessary to repeat steps 1-3 for each upgrade.4. Perform the upgrade. The upgrade should be done from the DOS prompt. Attach a keyboard to the MMS computer. With the MMS program running press "ALT"and "F4" at the same time. This will exit the MMS program. Press "ALT"and "F4" at the same time again and you will get a dialog box that asks you to confirm you want to end your Windows session. Press "ENTER" to confirm. Install the floppy labeled "Winfile.exe Y2K Upgrade" into the floppy drive on the MMS

Completion Date

February 29, 2000Termination Date

February 29, 2000Problem

Upgrade software needs to be installed on certain 3606, 3608, 3612, and 3616 diesel engines with the Marine Monitoring System (MMS) to become Y2K compatible.

Affected Product

Model & Identification Number

3606 (8RB29, 8RB656-661, 8RB669, 8RB672-673, 8RB680-688, 8RB691-00692, 8RB695-702, 8RB711-00713, 8RB715, 8RB717-718, 8RB721-723)

3608 (6MC535-536, 6MC550, 6MC561-562, 6MC582-586)

3612 (9RC230, 9RC242, 9RC247-253, 9RC256-257, 9RC259-260)

3616 (1PD289-293, 1PD295, 1PD306, 1PD308, 1PD313-336)

Parts Needed

- Dealers will need to obtain the Upgrade Files for this program.- 1 Blank formatted 1.44 MB floppy disk for Winfile Upgrade- 6 Blank formatted 1.44 MB floppy disks for InTouch 5.6B UpgradeAction Required

See the attached procedure.

Owner Notification

U.S. and Canadian owners will receive the attached Owner Notification.

Service Claim Allowances

This is a 1-hour job.

U.S. and Canadian Dealers Only - Eligible dealers may enter a Type 2 SIMS Report.

Parts Disposition

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

MAKE EVERY EFFORT TO COMPLETE THIS PROGRAM AS SOON AS POSSIBLE.

Attach.(1-Owner Notification)(1-Rework Procedure)Copy Of Owner Notification For U.S. And Canadian Owners

Rework Procedure

Windows 3.11 Winfile Upgrade

This upgrade is necessary for Windows 3.11 to correctly date stamp files after the year 2000, The first three steps in the following procedure will be done in the office or shop.

1. Obtain the file. The file can be obtained from the Caterpillar Mailbox, SISWEB, or from the SIS disks that are released monthly. The file part number is 174-8693.2. Unzip the file. The 174-8693.exe file is a self-executing zip file. To Unzip, place the file in a known location on the hard drive. Run the file. At the dialog box type in 'A:\' where it asks for the folder to place unzipped files. Install a blank formatted disk into the A: drive. Select UNZIP or press "ENTER". This will unzip the files to the floppy drive. If your floppy drive is not 'A:' substitute your floppy drive letter for A in the above instuctions.)

3. Label the disk. This disk should be labeled "Winfile.exe Y2K Upgrade". This disk or a copy of this disk can be used to do multiple upgrades. It is not necessary to repeat steps 1-3 for each upgrade.4. Perform the upgrade. The upgrade should be done from the DOS prompt. Attach a keyboard to the MMS computer. With the MMS program running press "ALT"and "F4" at the same time. This will exit the MMS program. Press "ALT"and "F4" at the same time again and you will get a dialog box that asks you to confirm you want to end your Windows session. Press "ENTER" to confirm. Install the floppy labeled "Winfile.exe Y2K Upgrade" into the floppy drive on the MMS

Have questions with 101603-7811?

Group cross 101603-7811 ZEXEL

Isuzu

101603-7811

9 400 615 216

1156027861

INJECTION-PUMP ASSEMBLY

6BG1-TC1

6BG1-TC1