Information injection-pump assembly

ZEXEL

101603-7800

1016037800

ISUZU

8943935840

8943935840

Rating:

Cross reference number

ZEXEL

101603-7800

1016037800

ISUZU

8943935840

8943935840

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-4920

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.2

4.15

4.25

Rack position

After adjusting injection quantity. R=A

After adjusting injection quantity. R=A

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

11.1

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

66.9

65.3

68.5

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

265

265

265

Average injection quantity

mm3/st.

9

7.7

10.3

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.1)

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

66.9

65.9

67.9

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1-0.1

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

78.5

74.5

82.5

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1-0.3

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

49.7

46.5

52.9

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

I

Rack position

-

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

99

99

131

Fixing the lever

*

Timer adjustment

Pump speed

r/min

(1220)

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1300

Advance angle

deg.

1.3

0.8

1.8

Timer adjustment_03

Pump speed

r/min

1500

Advance angle

deg.

5.5

5

6

Remarks

Finish

Finish

Test data Ex:

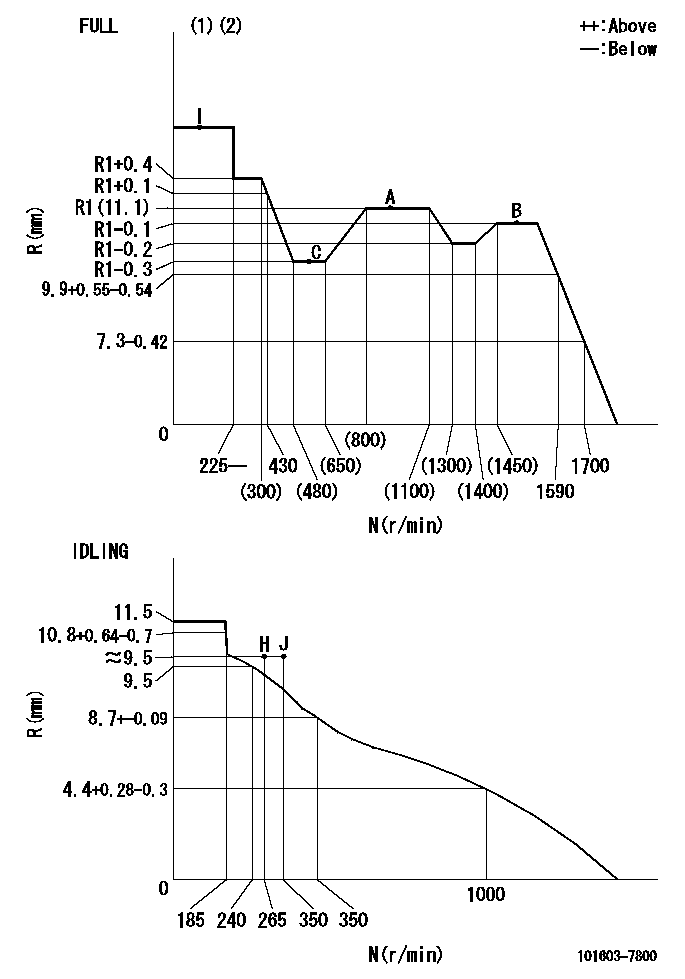

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

----------

T1=G22

----------

----------

T1=G22

----------

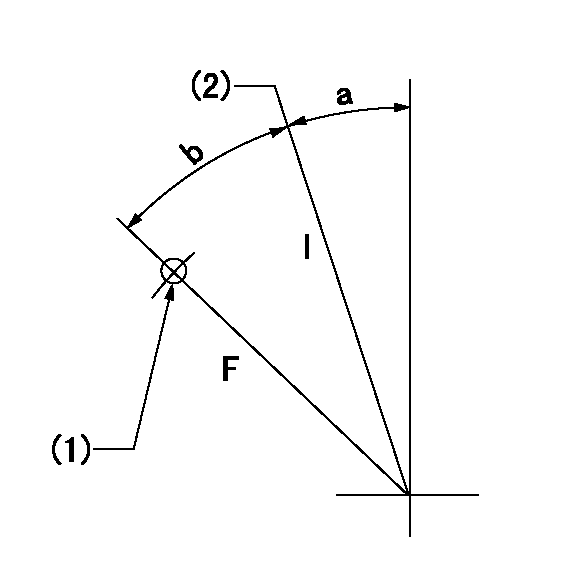

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=53mm

----------

a=11deg+-5deg b=38deg+-3deg

----------

aa=53mm

----------

a=11deg+-5deg b=38deg+-3deg

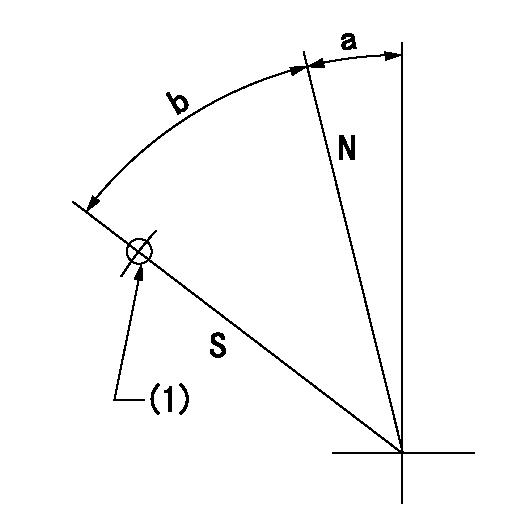

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the pin at R = aa

----------

aa=67mm

----------

a=16deg+-5deg b=29deg+-5deg

----------

aa=67mm

----------

a=16deg+-5deg b=29deg+-5deg

0000001501 I/P WITH LOAD PLUNGER ADJ

Plunger assembly number: PL (stamping: ST)

1. Adjustment procedures

(1)Insert the pre-stroke adjusting shims L1 for each cylinder.

(2)Adjust injection quantity.(max. var. bet. cyl. idling a1, full a2)

(3)At basic point A, adjust so that the pre-stroke is L2.

(4)Reconfirm the injection quantity.

----------

PL=131153-4520 ST=A724 L1=1mm L2=4.2+-0.05mm a1=+-14% a2=+-2.5%

----------

----------

PL=131153-4520 ST=A724 L1=1mm L2=4.2+-0.05mm a1=+-14% a2=+-2.5%

----------

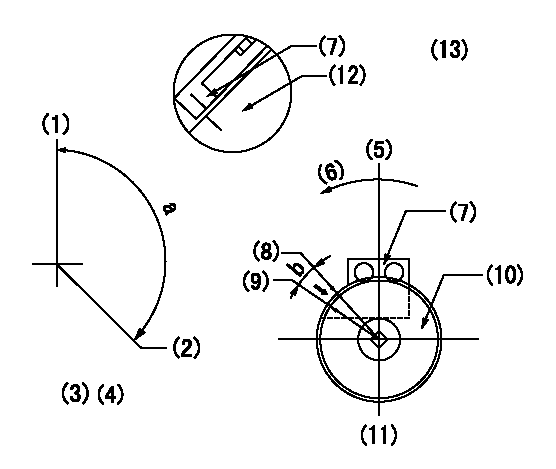

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

(5)Pump vertical direction

(6)Direction of rotation

(7)Pointer

(8)Pointer stamping

(9)Timing device stamping

(10)Timing device

(11)Stamp both at the same time as shown above.

(12)Outside circumference of timing device

(13)Secondary timing stamping position for the No. 1 cylinder's beginning of injection

----------

aa=11deg bb=1deg

----------

a=(150deg) b=1deg

----------

aa=11deg bb=1deg

----------

a=(150deg) b=1deg

Information:

This Program can be administered either before or after a failure. In either case the decision whether to apply the Program is made by the dealer. When reporting the repair, use "PS9436" as the Part Number and "7755" as the Group Number. If administered before failure, use "56" as the Warranty Claim Description Code and use "T" as the SIMS Description Code. If administered after failure, use "96" as the Warranty Claim Description Code and use "Z" as the SIMS Description Code.

Termination Date

March 31, 1999Problem

Engines may experience ingress of coolant to the fuel system or vice versa due to the degradation of the sleeve seal-o-rings and the unit injector seal-o-rings. The contamination of coolant into the fuel system affects engine performance and can cause injector seizure. Contamination of fuel in the cooling system may reduce cooling performance.

Affected Product

Model & Identification Number

The work outlined in this program is to occur once only for the following engines with a minimum of 300,000 liters of fuel burned. In most applications this generally corresponds to:

*Every 300,000 kms of engine life for B-Triple and Triple Road Trains.*Every 450,000 kms of engine life for B-Double and Double Road Trains.*Every 600,000 kms of engine life for Single Trailers.3406E (5EK1-Up 6TS1-Up 1LW1-Up 5DS1-Up )

Parts Needed

6 - 9X7317 SEAL-O RING (Lower Seal-0-ring of unit Injector),6 - 9X7418 SEAL-O RING (Upper Seal-0-ring of Unit Injector),6 - 9X7419 SEAL-O RING (Mddle Seal-0-ring of Unit Injector),6 - 9X7430 SEAL-O-RING (Upper Seat-0-ring of unit Injector Sleeve),12- 9X7431 SEAL-O-RING (Lower Seal-0-ring of unit Injector Sleeve, two per sleeve),Action Required

See the attached procedure.

Service Claim Allowances

This job varies by cab type.

*See labor breakdowns. Labor Hours By Cab Type Parts Disposition

Please return seal-o-rings packaged in plastic bags, with relevant history of the truck and engine, to:

Steve Keenan,

Application and Service Engineer-

Caterpillar of Australia.

Private Mailbag 4.

Tuilamarine. 3043.

Handle all other parts in accordance with your Warranty Bulletin on warranty parts handling.

(1-Rework Procedure)Rework Procedure

1. Refer to attached parts book drawings.2. Obtain an ECM print-out from the Truck. Retain this print-out.3. Remove set of unit injectors. (Code 1290-010: refer p.109 of TRG for 3406E on highway truck engines;4. Drain and collect coolant.5. Remove and install set of unit injector sleeves (Code 1713-010: refer p. 111 of TRG).6. Replace injector body seals and sleeve seals. Return seals only as per parts disposition.7. Install set of unit injectors.8. Refill with coolant.9. Install set of unit injector sleeves.

Illustration 1.

Illustration 2.

Termination Date

March 31, 1999Problem

Engines may experience ingress of coolant to the fuel system or vice versa due to the degradation of the sleeve seal-o-rings and the unit injector seal-o-rings. The contamination of coolant into the fuel system affects engine performance and can cause injector seizure. Contamination of fuel in the cooling system may reduce cooling performance.

Affected Product

Model & Identification Number

The work outlined in this program is to occur once only for the following engines with a minimum of 300,000 liters of fuel burned. In most applications this generally corresponds to:

*Every 300,000 kms of engine life for B-Triple and Triple Road Trains.*Every 450,000 kms of engine life for B-Double and Double Road Trains.*Every 600,000 kms of engine life for Single Trailers.3406E (5EK1-Up 6TS1-Up 1LW1-Up 5DS1-Up )

Parts Needed

6 - 9X7317 SEAL-O RING (Lower Seal-0-ring of unit Injector),6 - 9X7418 SEAL-O RING (Upper Seal-0-ring of Unit Injector),6 - 9X7419 SEAL-O RING (Mddle Seal-0-ring of Unit Injector),6 - 9X7430 SEAL-O-RING (Upper Seat-0-ring of unit Injector Sleeve),12- 9X7431 SEAL-O-RING (Lower Seal-0-ring of unit Injector Sleeve, two per sleeve),Action Required

See the attached procedure.

Service Claim Allowances

This job varies by cab type.

*See labor breakdowns. Labor Hours By Cab Type Parts Disposition

Please return seal-o-rings packaged in plastic bags, with relevant history of the truck and engine, to:

Steve Keenan,

Application and Service Engineer-

Caterpillar of Australia.

Private Mailbag 4.

Tuilamarine. 3043.

Handle all other parts in accordance with your Warranty Bulletin on warranty parts handling.

(1-Rework Procedure)Rework Procedure

1. Refer to attached parts book drawings.2. Obtain an ECM print-out from the Truck. Retain this print-out.3. Remove set of unit injectors. (Code 1290-010: refer p.109 of TRG for 3406E on highway truck engines;4. Drain and collect coolant.5. Remove and install set of unit injector sleeves (Code 1713-010: refer p. 111 of TRG).6. Replace injector body seals and sleeve seals. Return seals only as per parts disposition.7. Install set of unit injectors.8. Refill with coolant.9. Install set of unit injector sleeves.

Illustration 1.

Illustration 2.