Information injection-pump assembly

BOSCH

9 400 615 208

9400615208

ZEXEL

101603-7721

1016037721

ISUZU

8943933422

8943933422

Rating:

Service parts 101603-7721 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

8-94397-483-2

12.

Open Pre:MPa(Kqf/cm2)

18.1{185}

15.

NOZZLE SET

Include in #1:

101603-7721

as INJECTION-PUMP ASSEMBLY

Include in #2:

104741-6890

as _

Cross reference number

BOSCH

9 400 615 208

9400615208

ZEXEL

101603-7721

1016037721

ISUZU

8943933422

8943933422

Zexel num

Bosch num

Firm num

Name

101603-7721

9 400 615 208

8943933422 ISUZU

INJECTION-PUMP ASSEMBLY

6HE1-S * K

6HE1-S * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-4920

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.2

4.15

4.25

Rack position

After adjusting injection quantity. R=A

After adjusting injection quantity. R=A

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

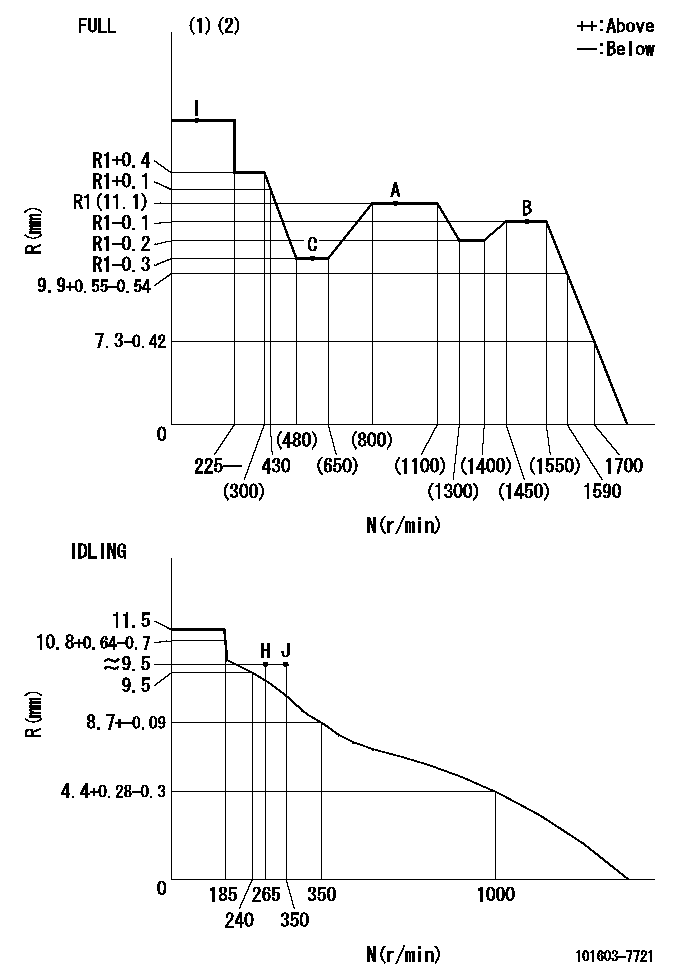

Injection quantity adjustment

Adjusting point

-

Rack position

11.1

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

66.9

65.3

68.5

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

265

265

265

Average injection quantity

mm3/st.

9

7.7

10.3

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.1)

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

66.9

65.9

67.9

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1-0.1

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

78.5

74.5

82.5

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1-0.3

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

49.7

46.5

52.9

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

I

Rack position

-

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

99

99

131

Fixing the lever

*

Timer adjustment

Pump speed

r/min

1210--

Advance angle

deg.

0

0

0

Load

3/4

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1160

Advance angle

deg.

0.3

Load

3/4

Timer adjustment_03

Pump speed

r/min

1500

Advance angle

deg.

5.5

5

6

Load

4/4

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

----------

T1=G22

----------

----------

T1=G22

----------

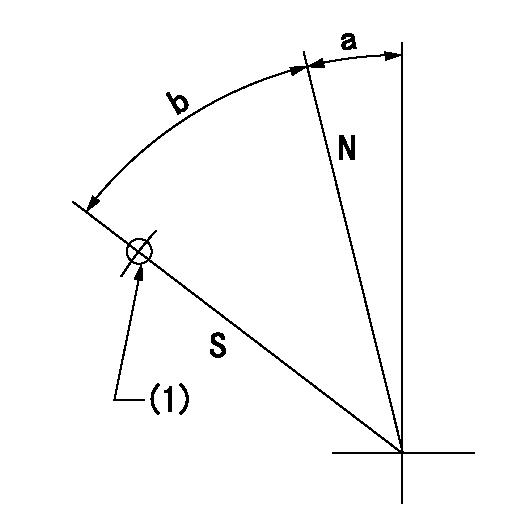

Speed control lever angle

F:Full speed

I:Idle

(1)Use the pin at R = aa

(2)Stopper bolt set position 'H'

----------

aa=35mm

----------

a=11deg+-5deg b=38deg+-3deg

----------

aa=35mm

----------

a=11deg+-5deg b=38deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the pin at R = aa

----------

aa=62.5mm

----------

a=12.5deg+-5deg b=29deg+-5deg

----------

aa=62.5mm

----------

a=12.5deg+-5deg b=29deg+-5deg

0000001501 I/P WITH LOAD PLUNGER ADJ

Plunger assembly number: PL (stamping: ST)

1. Adjustment procedures

(1)Insert the pre-stroke adjusting shims L1 for each cylinder.

(2)Adjust injection quantity.(max. var. bet. cyl. idling a1, full a2)

(3)At basic point A, adjust so that the pre-stroke is L2.

(4)Reconfirm the injection quantity.

----------

PL=131153-4520 ST=A724 L1=1mm L2=4.2+-0.05mm a1=+-14% a2=+-2.5%

----------

----------

PL=131153-4520 ST=A724 L1=1mm L2=4.2+-0.05mm a1=+-14% a2=+-2.5%

----------

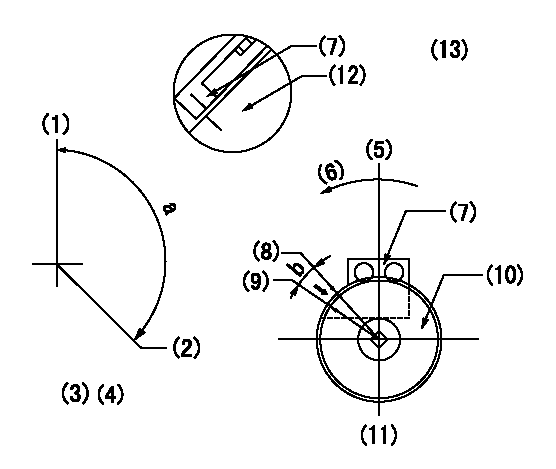

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

(5)Pump vertical direction

(6)Direction of rotation

(7)Pointer

(8)Pointer stamping

(9)Timing device stamping

(10)Timing device

(11)Stamp both at the same time as shown above.

(12)Outside circumference of timing device

(13)Secondary timing stamping position for the No. 1 cylinder's beginning of injection

----------

aa=11deg bb=1deg

----------

a=(150deg)

----------

aa=11deg bb=1deg

----------

a=(150deg)

Information:

Parts Needed

Group 1

6 - 1136145 Seat6 - 1136303 Seal-O-Ring1 - 1192940 Gasket6 - 1249714 Tube Assembly6 - 1265424 Clamp-InjectorGroup 2

6 - 0R4970 Injector (for 230 HP and Above)6 - 0R4972 Injector (for 210 HP and Below)6 - 1136303 Seal O-Ring (if not included in group 1)6 - 1148718 Seal O-Ring1 - 1192940 Gasket (if not included in group 1)6 - 1231199 Seal6 - 1258274 Seal O-RingAction Required

See attached rework procedure.

Service Claim Allowances

Group 1

Affected Product

* After failure repairs made prior to January 1, 1996 should claim actual reasonable time. * After failure repairs made January 1, 1996 or later should use the 3126 Time Requirement Guide to determine additional labor hours.

* Before failure repair should claim the labor hours listed below:

If Group 1 and Group 2 repairs are performed, claim Group 2 SMCS Codes ONLY.

Add an additional 1.6 Hours to both groups 1 and 2 if the procedure is done in a motor home.

Parts Stock

Submit one claim for all 1249714 Tube Assemblies removed from Parts Stock.

US and Canadian Dealers Only - When submitting a Parts Stock claim use 99Z00007 in the Product Identification Number Field.

TEPS/MEPS dealers must return the affected Parts Stock to their Caterpillar dealer for replacement.

Group 2

Add an additional 1.6 Hours to both groups 1 and 2 if the procedure is done in a motor home.

Parts Disposition

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Attach.(1-Rework Procedure)Rework Procedure

Group 1

Affected Product

Jumper Tube Removal

1. Loosen, but do not back off the jumper tube flare nut at the end nearest the high pressure oil manifold, using the 5P0144 Crow's Foot Socket.2. Remove the 8T0292 Bolt and the fuel injector hold-down clamp.3. Loosen and back out the #10 Allen head bolts at the fuel injector using the 1252584 Ball Head Hex Drive Bit (4mm). Leave the bolts in the jumper tube flange while removing the jumper tube. Retain the bolts for reassembly.4. Stabilize the top of the tube with one finger and back out the nut at the mainfold end of the tube.5. Carefully remove the jumper tube from the fuel injector and oil manifold.6. Remove the jumper tube seat and O-ring from the top of the fuel injector. A magnet is recommended for picking up the seat.

7. Retain the removed jumper tube, seat, and O-ring until the warranty claim is processed.Jumper Tube Installation

1. Place a new 1136303 O-Ring into the channel on top of the fuel injector. Do not use STP to lube O-rings. STP traps moisture and will cause rust buildup in the O-ring groove.

2. Place a new 1136145 Jumper Tube Seat over the O-ring on top of the injector. The earlier tubes have a shiny appearance on the two bolt flange. The new tubes have a phosphate and oil coating, which is black, similar in color to an internal engine bolt.

The following guidelines should be used to identify parts in the system. The date code on the 1249714 Tube plastic wrapper is in the form 01996476. The first four numbers represent the month and year,

Group 1

6 - 1136145 Seat6 - 1136303 Seal-O-Ring1 - 1192940 Gasket6 - 1249714 Tube Assembly6 - 1265424 Clamp-InjectorGroup 2

6 - 0R4970 Injector (for 230 HP and Above)6 - 0R4972 Injector (for 210 HP and Below)6 - 1136303 Seal O-Ring (if not included in group 1)6 - 1148718 Seal O-Ring1 - 1192940 Gasket (if not included in group 1)6 - 1231199 Seal6 - 1258274 Seal O-RingAction Required

See attached rework procedure.

Service Claim Allowances

Group 1

Affected Product

* After failure repairs made prior to January 1, 1996 should claim actual reasonable time. * After failure repairs made January 1, 1996 or later should use the 3126 Time Requirement Guide to determine additional labor hours.

* Before failure repair should claim the labor hours listed below:

If Group 1 and Group 2 repairs are performed, claim Group 2 SMCS Codes ONLY.

Add an additional 1.6 Hours to both groups 1 and 2 if the procedure is done in a motor home.

Parts Stock

Submit one claim for all 1249714 Tube Assemblies removed from Parts Stock.

US and Canadian Dealers Only - When submitting a Parts Stock claim use 99Z00007 in the Product Identification Number Field.

TEPS/MEPS dealers must return the affected Parts Stock to their Caterpillar dealer for replacement.

Group 2

Add an additional 1.6 Hours to both groups 1 and 2 if the procedure is done in a motor home.

Parts Disposition

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Attach.(1-Rework Procedure)Rework Procedure

Group 1

Affected Product

Jumper Tube Removal

1. Loosen, but do not back off the jumper tube flare nut at the end nearest the high pressure oil manifold, using the 5P0144 Crow's Foot Socket.2. Remove the 8T0292 Bolt and the fuel injector hold-down clamp.3. Loosen and back out the #10 Allen head bolts at the fuel injector using the 1252584 Ball Head Hex Drive Bit (4mm). Leave the bolts in the jumper tube flange while removing the jumper tube. Retain the bolts for reassembly.4. Stabilize the top of the tube with one finger and back out the nut at the mainfold end of the tube.5. Carefully remove the jumper tube from the fuel injector and oil manifold.6. Remove the jumper tube seat and O-ring from the top of the fuel injector. A magnet is recommended for picking up the seat.

7. Retain the removed jumper tube, seat, and O-ring until the warranty claim is processed.Jumper Tube Installation

1. Place a new 1136303 O-Ring into the channel on top of the fuel injector. Do not use STP to lube O-rings. STP traps moisture and will cause rust buildup in the O-ring groove.

2. Place a new 1136145 Jumper Tube Seat over the O-ring on top of the injector. The earlier tubes have a shiny appearance on the two bolt flange. The new tubes have a phosphate and oil coating, which is black, similar in color to an internal engine bolt.

The following guidelines should be used to identify parts in the system. The date code on the 1249714 Tube plastic wrapper is in the form 01996476. The first four numbers represent the month and year,

Have questions with 101603-7721?

Group cross 101603-7721 ZEXEL

Isuzu

101603-7721

9 400 615 208

8943933422

INJECTION-PUMP ASSEMBLY

6HE1-S

6HE1-S