Information injection-pump assembly

ZEXEL

101603-7580

1016037580

ISUZU

8943968890

8943968890

Rating:

Cross reference number

ZEXEL

101603-7580

1016037580

ISUZU

8943968890

8943968890

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-4920

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

RED3 control unit part number

407910-2

470

RED3 rack sensor specifications

mm

15

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.2

4.15

4.25

Rack position

After adjusting injection quantity. R=A

After adjusting injection quantity. R=A

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Rack position

(9.3)

Vist

V

2.14

2.14

2.14

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

73.5

72.5

74.5

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Injection quantity adjustment_02

Rack position

(7.6)

Vist

V

2.5

2.4

2.6

Pump speed

r/min

260

260

260

Average injection quantity

mm3/st.

8.3

7

9.6

Max. variation between cylinders

%

0

-14

14

Governor adjustment

Pump speed

r/min

1210--

Advance angle

deg.

0

0

0

Load

3/4

Remarks

Start

Start

Governor adjustment_02

Pump speed

r/min

1160

Advance angle

deg.

0.3

Load

3/4

Governor adjustment_03

Pump speed

r/min

1500

Advance angle

deg.

5.5

5

6

Load

4/4

Remarks

Finish

Finish

Test data Ex:

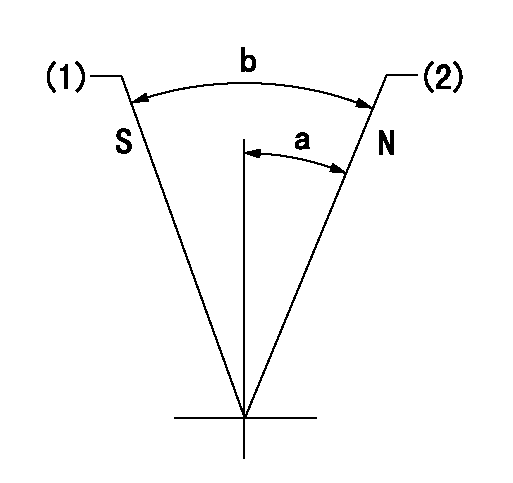

Speed control lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

(2)Rack position bb

----------

aa=1mm bb=16mm

----------

a=19deg+-5deg b=29deg+-5deg

----------

aa=1mm bb=16mm

----------

a=19deg+-5deg b=29deg+-5deg

0000000901

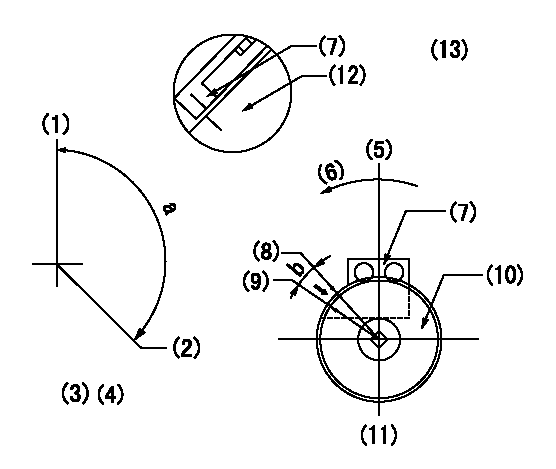

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

(5)Pump vertical direction

(6)Direction of rotation

(7)Pointer

(8)Pointer stamping

(9)Timing device stamping

(10)Timing device

(11)Move b deg and stamp both at the same time as shown above.

(12)Outside circumference of timing device

(13)Secondary timing stamping position for the No. 1 cylinder's beginning of injection

----------

aa=11deg

----------

a=(150deg) b=1deg

----------

aa=11deg

----------

a=(150deg) b=1deg

Stop lever angle

(Rs) rack sensor specifications

(C/U) control unit part number

(V) Rack sensor output voltage

(R) Rack position (mm)

1. Confirming governor output characteristics (rack 15 mm, span 6 mm)

(1)When the output voltages of the rack sensor are V1 and V2, check that the rack positions R1 and R2 in the table above are satisfied.

----------

----------

----------

----------

Information:

Illustration 9 g06426461

(1) For 323, 330, and 330GC machines use 580-1893 Plate As / For 336GC machines use 581-5268 Plate As

(Q) Bolt and washer

(R) Plate

Install plate assembly (1) using plate (R), bolt, and washer (Q). Tighten the bolts to 55 10 N m (41 7 lb ft). Refer to Illustration 9.

Illustration 10 g06426462

(7) 365-0162 Special Connector

(F) Injector

Install special connector (7) to injector (F). Refer to Illustration 10.

Illustration 11 g06426463

(2) 573-8722 Tank

(8) 3S-2093 Cable Strap

(E) Hose

(M) Harness

Connect hose (E) to tank (2). Refer to Illustration 11.

Illustration 12 g06426465

View of area T

(1) For 323, 330, and 330GC machines use 580-1893 Plate As / For 336GC machines use 581-5268 Plate As

(P) Clip

(S) Bolt and washer

(D1) 45 Degree

Install clip (P) using bolt and washer (S), torque to 28 7 N m (248 62 lb in). Refer to Illustration 12.

Secure the harness (M) using cable strap (8). After tie up, cut all the surplus of strap. Refer to Illustration 11.

Reinstall upper cover (A) and close the upper cover (B). Refer to Illustration 1 and Illustration 2.Replacement Procedure for 336 Excavators

Do not operate or work on this product unless you have read and understood the instruction and warnings in the relevant Operation and Maintenance Manuals and relevant service literature. Failure to follow the instructions or heed the warnings could result in injury or death. Proper care is your responsibility.

Table 3

Required Parts

Item Qty Part Number Part Name

1 1 471-9926 Tank

2 1 581-3324 Plate As

3 1 327-0325 Cable Strap

Illustration 13 g06426466

(A) Upper cover

(B) Upper cover

Remove the upper cover (A) and open the upper cover (B). Refer to Illustration 13.

Illustration 14 g06426467

(C) Tank assembly

(E) Hose

(F) Hose

(G) Strap

Disconnect hose (E) and hose (F) from tank assembly (C). Cut and remove the strap (G). Refer to Illustration 14.

Illustration 15 g06426468

(C) Tank assembly

(H) Bolt and washer

(J) Bolt and washer

(K) Plate assembly

Remove tank assembly (C) by loosening the bolt and washer (H). Refer to Illustration 15.

Remove plate assembly (K) by loosening the bolt and washer (J). Refer to Illustration 15.

Illustration 16 g06426469

(F) Hose

(D1) 10.0 mm (0.4 inch)

Cut and remove the end of hose (F) by 10.0 mm (0.4 inch). Refer to Illustration 16.

Illustration 17 g06426470

(1) 471-9926 Tank

(2) 581-3324 Plate As

(3) 327-0325 Cable Strap

(E) Hose

(H) Bolt and washer

(J) Bolt and washer

(F) Hose

Install the plate assembly (2) and tank (1) using bolt and washer (J) and bolt and washer (H). Refer to Illustration 17.

Connect hose (E) and hose (F) to tank (1). Add cable strap (3) to secure hose. After tie up, cut all the surplus of strap. Refer to Illustration 17.

Reinstall upper cover (A) and close the upper cover (B). Refer to Illustration 13.