Information injection-pump assembly

BOSCH

9 400 615 189

9400615189

ZEXEL

101603-7510

1016037510

ISUZU

1156026900

1156026900

Rating:

Service parts 101603-7510 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

1-15300-161-1

12.

Open Pre:MPa(Kqf/cm2)

22.1{225}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 615 189

9400615189

ZEXEL

101603-7510

1016037510

ISUZU

1156026900

1156026900

Zexel num

Bosch num

Firm num

Name

101603-7510

9 400 615 189

1156026900 ISUZU

INJECTION-PUMP ASSEMBLY

6SA1-T K 14BF INJECTION PUMP ASSY PE6AD PE

6SA1-T K 14BF INJECTION PUMP ASSY PE6AD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.7

4.65

4.75

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

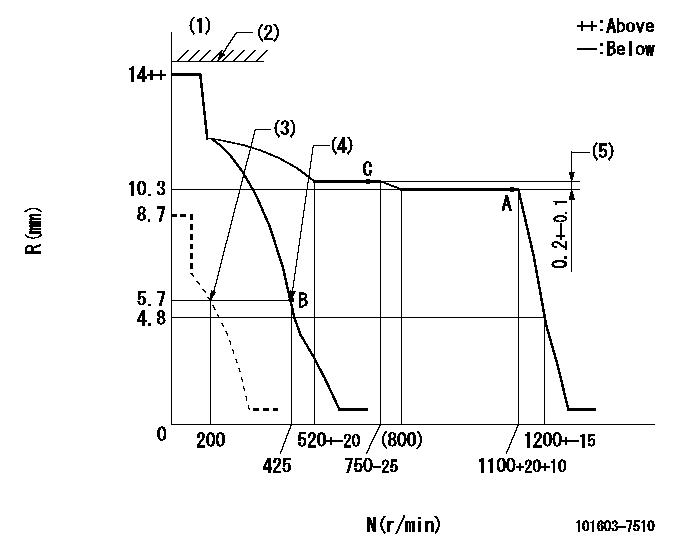

Injection quantity adjustment

Adjusting point

A

Rack position

10.3

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

123.6

122.6

124.6

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

5.7+-0.5

Pump speed

r/min

425

425

425

Average injection quantity

mm3/st.

9.1

7.1

11.1

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Timer adjustment

Pump speed

r/min

850--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

800

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1120

Advance angle

deg.

1

0.5

1.5

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT not operating.

(3)Set idle sub-spring

(4)Main spring setting

(5)Rack difference between N = N1 and N = N2

----------

K=12 N1=1100r/min N2=700r/min

----------

----------

K=12 N1=1100r/min N2=700r/min

----------

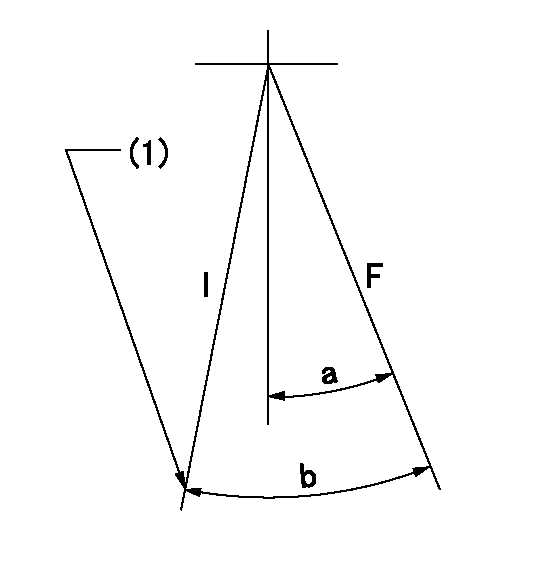

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=10deg+-5deg b=25deg+-5deg

----------

----------

a=10deg+-5deg b=25deg+-5deg

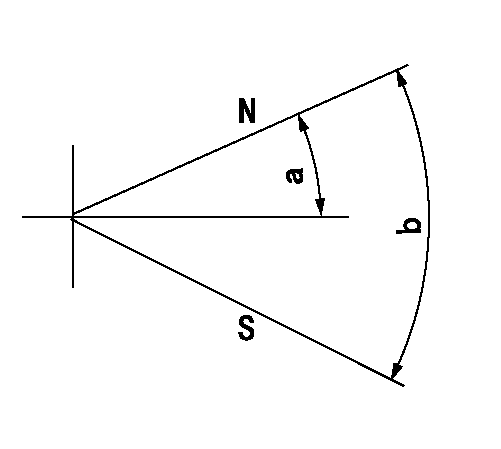

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=19deg+-5deg b=53deg+-5deg

----------

----------

a=19deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=18deg

----------

a=(40deg)

----------

aa=18deg

----------

a=(40deg)

Information:

Parts Location

Illustration 2 g01631813

(A) Flywheel (B) Fender Group (C) Tank Group (1) 319-8929 Diesel Particulate Filter Gp (2) 329-1696 Tube (3) 329-1701 Tube As (4) 295-3044 Exhaust Support Gp (5) 8T-4223 Hard Washer (6) 8T-4183 Bolt (7) 270-0112 Bellows (8) 7E-3870 Muffler Clamp (9) 247-5011 Pipe Clamp (10) 9Y-8315 Pipe Clamp (11) 8S-5120 Extension Pipe (12) 7S-4994 Rain Cap As (13) 241-6170 Plug (14) 8T-6765 Pipe Plug Installation Procedure

Diesel Particulate Filter Installation

Illustration 3 g01630053

(4) 295-3044 Exhaust Support Gp (Lower half) (5) 8T-4223 Hard Washer (6) 8T-4183 Bolt

Install the lower half of each new 295-3044 Exhaust Support Gp (4) on top of the hood, towards the right side of the cab, by using four new 8T-4183 Bolts (6), and four new 8T-4223 Hard Washers (5). Refer to Illustration 3.

Illustration 4 g01630056

(1) 319-8929 Diesel Particulate Filter Gp

Install the new 319-8929 Diesel Particulate Filter Gp (1) onto the lower half of exhaust support group (4). Refer to Illustration 4.

Illustration 5 g01630074

(4a) Upper half (Exhaust support group) (4b) Bolt (4c) Hard washer (4d) Weld nut

Install the upper half (4a) of exhaust support group by using two bolts (4b), two hard washers (4c), and two weld nuts (4d). Repeat for the other exhaust support group. Refer to Illustration 5.

Illustration 6 g01630094

(2) 329-1696 Tube (3) 329-1701 Tube As (7) 270-0112 Bellows (8) 7E-3870 Muffler Clamp

Install the new 329-1696 Tube (2) to the inlet module tube of the diesel particulate filter group by using one new 7E-3870 Muffler Clamp (8). Refer to Illustration 6.

Install the new 270-0112 Bellows (7) to tube (2) by using one new 7E-3870 Muffler Clamp (8). Refer to Illustration 6.

Install the new 329-1701 Tube Assembly (3) to bellows (7) by using one new 7E-3870 Muffler Clamp (8). Refer to Illustration 6.

Illustration 7 g01630133

(9) 247-5011 Pipe Clamp (11) 8S-5120 Extension Pipe

Install 8S-5120 Extension Pipe (11) to the outlet module tube of the diesel particulate filter group by using a new 247-5011 Pipe Clamp (9). Refer to Illustration 7.

Illustration 8 g01630173

(12) 7S-4994 Rain Cap As

Install the new 7S-4994 Rain Cap Assembly (12) on extension pipe (11). Refer to Illustration 8.

Illustration 9 g01630234

(13) 241-6170 Plug (14) 8T-6765 Pipe Plug

Install a new 241-6170 Plug (13) and a new 8T-6765 Pipe Plug (14) on tube assembly (3) at the respective slots provided. Refer to Illustration 9.

Reconnect the drain lines.Exhaust Monitor Installation

Refer to Special Instruction, REHS5606, "Installation and Operation of the Caterpillar Diesel Particulate Filter (DPF) and the Diagnostic Module for Non-Road Machine Applications (Non-California Applications)" for information regarding the installation and the operation of the exhaust monitor.The exhaust monitor is a device designed to monitor the Caterpillar DPF system continuously. The exhaust monitor provides critical information to the vehicle operator and maintenance

Illustration 2 g01631813

(A) Flywheel (B) Fender Group (C) Tank Group (1) 319-8929 Diesel Particulate Filter Gp (2) 329-1696 Tube (3) 329-1701 Tube As (4) 295-3044 Exhaust Support Gp (5) 8T-4223 Hard Washer (6) 8T-4183 Bolt (7) 270-0112 Bellows (8) 7E-3870 Muffler Clamp (9) 247-5011 Pipe Clamp (10) 9Y-8315 Pipe Clamp (11) 8S-5120 Extension Pipe (12) 7S-4994 Rain Cap As (13) 241-6170 Plug (14) 8T-6765 Pipe Plug Installation Procedure

Diesel Particulate Filter Installation

Illustration 3 g01630053

(4) 295-3044 Exhaust Support Gp (Lower half) (5) 8T-4223 Hard Washer (6) 8T-4183 Bolt

Install the lower half of each new 295-3044 Exhaust Support Gp (4) on top of the hood, towards the right side of the cab, by using four new 8T-4183 Bolts (6), and four new 8T-4223 Hard Washers (5). Refer to Illustration 3.

Illustration 4 g01630056

(1) 319-8929 Diesel Particulate Filter Gp

Install the new 319-8929 Diesel Particulate Filter Gp (1) onto the lower half of exhaust support group (4). Refer to Illustration 4.

Illustration 5 g01630074

(4a) Upper half (Exhaust support group) (4b) Bolt (4c) Hard washer (4d) Weld nut

Install the upper half (4a) of exhaust support group by using two bolts (4b), two hard washers (4c), and two weld nuts (4d). Repeat for the other exhaust support group. Refer to Illustration 5.

Illustration 6 g01630094

(2) 329-1696 Tube (3) 329-1701 Tube As (7) 270-0112 Bellows (8) 7E-3870 Muffler Clamp

Install the new 329-1696 Tube (2) to the inlet module tube of the diesel particulate filter group by using one new 7E-3870 Muffler Clamp (8). Refer to Illustration 6.

Install the new 270-0112 Bellows (7) to tube (2) by using one new 7E-3870 Muffler Clamp (8). Refer to Illustration 6.

Install the new 329-1701 Tube Assembly (3) to bellows (7) by using one new 7E-3870 Muffler Clamp (8). Refer to Illustration 6.

Illustration 7 g01630133

(9) 247-5011 Pipe Clamp (11) 8S-5120 Extension Pipe

Install 8S-5120 Extension Pipe (11) to the outlet module tube of the diesel particulate filter group by using a new 247-5011 Pipe Clamp (9). Refer to Illustration 7.

Illustration 8 g01630173

(12) 7S-4994 Rain Cap As

Install the new 7S-4994 Rain Cap Assembly (12) on extension pipe (11). Refer to Illustration 8.

Illustration 9 g01630234

(13) 241-6170 Plug (14) 8T-6765 Pipe Plug

Install a new 241-6170 Plug (13) and a new 8T-6765 Pipe Plug (14) on tube assembly (3) at the respective slots provided. Refer to Illustration 9.

Reconnect the drain lines.Exhaust Monitor Installation

Refer to Special Instruction, REHS5606, "Installation and Operation of the Caterpillar Diesel Particulate Filter (DPF) and the Diagnostic Module for Non-Road Machine Applications (Non-California Applications)" for information regarding the installation and the operation of the exhaust monitor.The exhaust monitor is a device designed to monitor the Caterpillar DPF system continuously. The exhaust monitor provides critical information to the vehicle operator and maintenance

Have questions with 101603-7510?

Group cross 101603-7510 ZEXEL

Isuzu

101603-7510

9 400 615 189

1156026900

INJECTION-PUMP ASSEMBLY

6SA1-T

6SA1-T