Information injection-pump assembly

ZEXEL

101603-7420

1016037420

ISUZU

8943960311

8943960311

Rating:

Cross reference number

ZEXEL

101603-7420

1016037420

ISUZU

8943960311

8943960311

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8210

Nozzle

105780-0070

Bosch type code

DN12SD12T-1

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-4920

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.2

4.15

4.25

Rack position

After adjusting injection quantity. R=A

After adjusting injection quantity. R=A

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

11.2

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

73.5

71.9

75.1

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

260

260

260

Average injection quantity

mm3/st.

8.3

7

9.6

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.2)

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

73.5

72.5

74.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1-0.1

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

84.6

80.6

88.6

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1-0.3

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

55.3

52.1

58.5

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

I

Rack position

-

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

103

103

135

Fixing the lever

*

Timer adjustment

Pump speed

r/min

1210--

Advance angle

deg.

0

0

0

Load

3/4

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1160

Advance angle

deg.

0.3

Load

3/4

Timer adjustment_03

Pump speed

r/min

1500

Advance angle

deg.

5.5

5

6

Load

4/4

Remarks

Finish

Finish

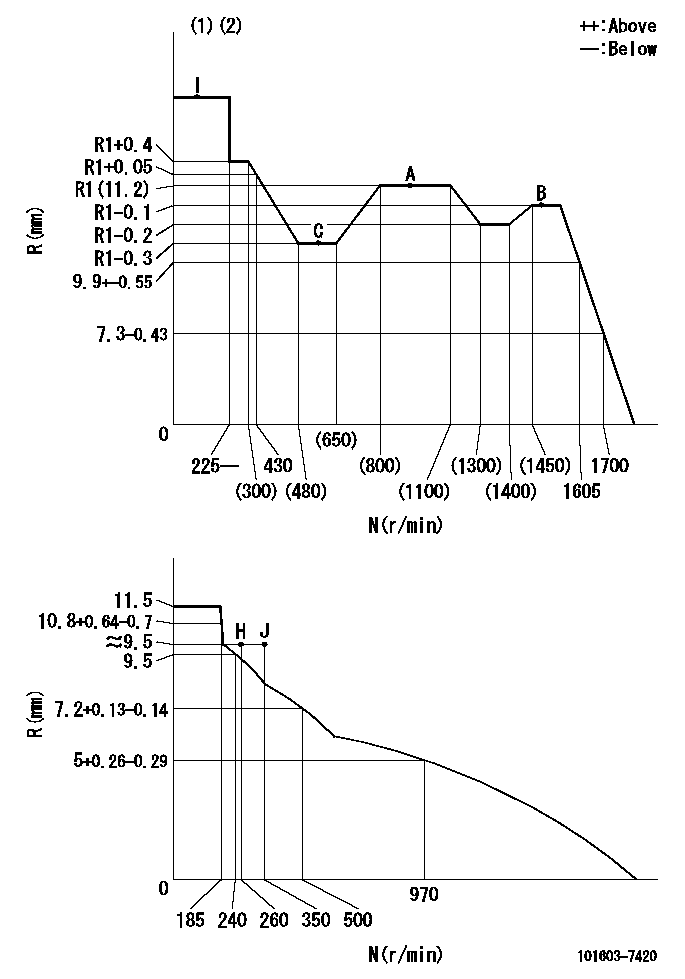

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

----------

T1=E76

----------

----------

T1=E76

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Use the pin at R = aa

(2)Stopper bolt set position 'H'

----------

aa=35mm

----------

a=11deg+-5deg b=(38deg)+-3deg

----------

aa=35mm

----------

a=11deg+-5deg b=(38deg)+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=12.5deg+-5deg b=40deg+-5deg

----------

----------

a=12.5deg+-5deg b=40deg+-5deg

0000001501 AIR CYLINDER

1. (1) Set the speed lever to idle.

(2)Screw in air cylinder (A)

(3)Set the clearance from the speed lever (B) at approximately L.

----------

L=1mm

----------

----------

L=1mm

----------

0000001601 I/P WITH LOAD PLUNGER ADJ

Plunger assembly number: PL (stamping: ST)

1. Adjustment procedures

(1)Insert the pre-stroke adjusting shims L1 for each cylinder.

(2)Adjust injection quantity.(max. var. bet. cyl. idling a1, full a2)

(3)At basic point A, adjust so that the pre-stroke is L2.

(4)Reconfirm the injection quantity.

----------

PL=131153-4520 ST=A724 L1=1mm L2=4.2+-0.05mm a1=+-14% a2=+-2.5%

----------

----------

PL=131153-4520 ST=A724 L1=1mm L2=4.2+-0.05mm a1=+-14% a2=+-2.5%

----------

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=10deg

----------

a=(150deg)

----------

aa=10deg

----------

a=(150deg)

Information:

Illustration 21 shows the direction the rack moves when the fuel injector is receiving fuel.

Illustration 22 g01455811

Illustration 1 - Flowchart for the Air in Fuel Test (Test F)

Illustration 23 g01455812

Illustration 2 - Flowchart for the Air in Fuel Test (Test F)Fuel Injector Cranking Test (Test G)

Note: The fuel injector cranking test checks for worn out injectors by measuring the cranking rack.

Illustration 24 g01412134

(3) The rack control (4) The number one fuel injectorNote: Refer to Illustration 24 for the location of the rack control and the location of the number one injector.

Illustration 25 g01412115

Flowchart for the Fuel Injector Cranking Test (Test G)Fuel Shutoff Solenoid Test (Test H)

Note: The fuel shutoff solenoid test determines if the fuel shutoff solenoid and wiring harness are operating properly.

Illustration 26 g01412143

Flowchart for the Fuel Shutoff Solenoid Test (Test H)Fuel Ratio Control (FRC) Setting Test (Test I)

Note: The FRC setting test checks the FRC setting.

Illustration 27 g01412145

Flowchart for the Fuel Ratio Control (FRC) Setting Test (Test I)Governor Servo Retaining Ring Test (Test J)

Note: Do not run the engine during this test.Note: The governor servo retaining ring test checks for faulty internal parts of the governor.

Illustration 28 g01422811

(1) Paddle

Illustration 29 g01422821

(2) Clevis pin

Illustration 30 g01412147

Flowchart for the Governor Servo Retaining Ring Test (Test J)Fuel Transfer Pump Test (Test K)

Note: The fuel transfer pump test is a visual inspection of the fuel transfer pump components.

Illustration 31 g01412150

(1) Screen (2) Inlet check valve (3) Spring (4) Bolt (5) Piston (6) Outlet check valve (7) Freeze plug (8) Piston check valve (9) Passage (10) Tappet Assembly (11) CamNote: Refer to Illustration 31 for the location of the components for the fuel transfer pump.

Illustration 32 g01412149

Flowchart for the Fuel Transfer Pump Test (Test K)Fuel Ratio Control (FRC) Diaphragm Leak Test (Test L)

Note: The FRC diaphragm leak test checks for a leaking FRC diaphragm.

Illustration 33 g01412154

Flowchart for the Fuel Ratio Control (FRC) Diaphragm Leak Test (Test L)

Illustration 22 g01455811

Illustration 1 - Flowchart for the Air in Fuel Test (Test F)

Illustration 23 g01455812

Illustration 2 - Flowchart for the Air in Fuel Test (Test F)Fuel Injector Cranking Test (Test G)

Note: The fuel injector cranking test checks for worn out injectors by measuring the cranking rack.

Illustration 24 g01412134

(3) The rack control (4) The number one fuel injectorNote: Refer to Illustration 24 for the location of the rack control and the location of the number one injector.

Illustration 25 g01412115

Flowchart for the Fuel Injector Cranking Test (Test G)Fuel Shutoff Solenoid Test (Test H)

Note: The fuel shutoff solenoid test determines if the fuel shutoff solenoid and wiring harness are operating properly.

Illustration 26 g01412143

Flowchart for the Fuel Shutoff Solenoid Test (Test H)Fuel Ratio Control (FRC) Setting Test (Test I)

Note: The FRC setting test checks the FRC setting.

Illustration 27 g01412145

Flowchart for the Fuel Ratio Control (FRC) Setting Test (Test I)Governor Servo Retaining Ring Test (Test J)

Note: Do not run the engine during this test.Note: The governor servo retaining ring test checks for faulty internal parts of the governor.

Illustration 28 g01422811

(1) Paddle

Illustration 29 g01422821

(2) Clevis pin

Illustration 30 g01412147

Flowchart for the Governor Servo Retaining Ring Test (Test J)Fuel Transfer Pump Test (Test K)

Note: The fuel transfer pump test is a visual inspection of the fuel transfer pump components.

Illustration 31 g01412150

(1) Screen (2) Inlet check valve (3) Spring (4) Bolt (5) Piston (6) Outlet check valve (7) Freeze plug (8) Piston check valve (9) Passage (10) Tappet Assembly (11) CamNote: Refer to Illustration 31 for the location of the components for the fuel transfer pump.

Illustration 32 g01412149

Flowchart for the Fuel Transfer Pump Test (Test K)Fuel Ratio Control (FRC) Diaphragm Leak Test (Test L)

Note: The FRC diaphragm leak test checks for a leaking FRC diaphragm.

Illustration 33 g01412154

Flowchart for the Fuel Ratio Control (FRC) Diaphragm Leak Test (Test L)