Information injection-pump assembly

ZEXEL

101603-7401

1016037401

ISUZU

1156026591

1156026591

Rating:

Cross reference number

ZEXEL

101603-7401

1016037401

ISUZU

1156026591

1156026591

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8210

Nozzle

105780-0070

Bosch type code

DN12SD12T-1

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-4920

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.7

3.65

3.75

Rack position

After adjusting injection quantity. R=A

After adjusting injection quantity. R=A

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

12.3

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

79

77.4

80.6

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

260

260

260

Average injection quantity

mm3/st.

9.1

7.1

11.1

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(12.3)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

79

78

80

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.1

Pump speed

r/min

1350

1350

1350

Average injection quantity

mm3/st.

92.2

89

95.4

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

I

Rack position

-

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

121

121

153

Fixing the lever

*

Timer adjustment

Pump speed

r/min

900--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

850

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

(900)

Advance angle

deg.

1

0.5

1.5

Remarks

Measure the actual speed.

Measure the actual speed.

Timer adjustment_04

Pump speed

r/min

1125

Advance angle

deg.

1

0.5

1.5

Timer adjustment_05

Pump speed

r/min

1275

Advance angle

deg.

5

4.5

5.5

Remarks

Finish

Finish

Test data Ex:

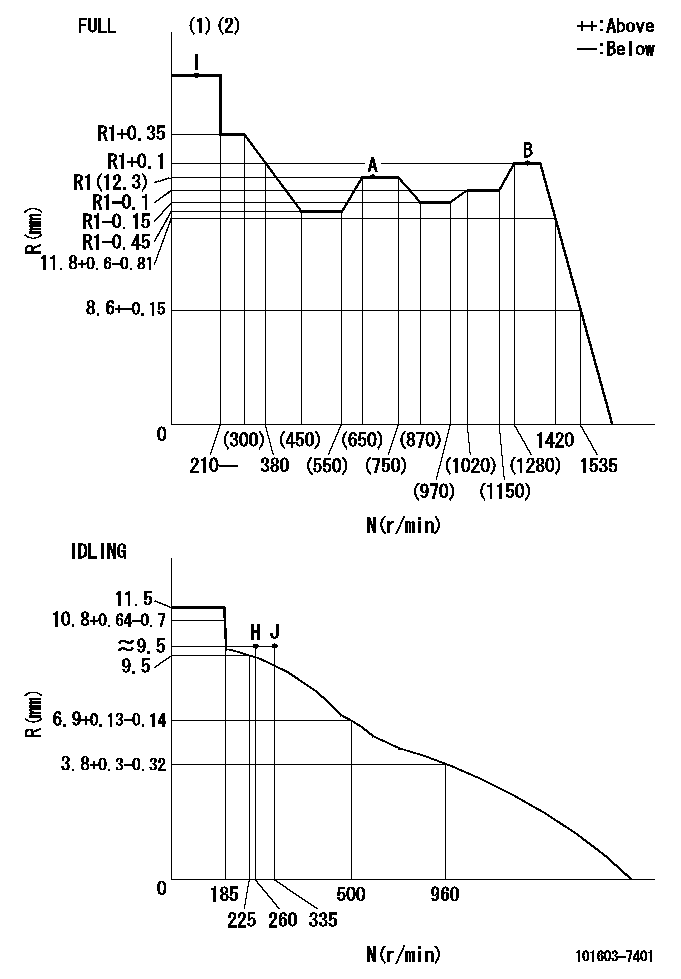

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

----------

T1=E94

----------

----------

T1=E94

----------

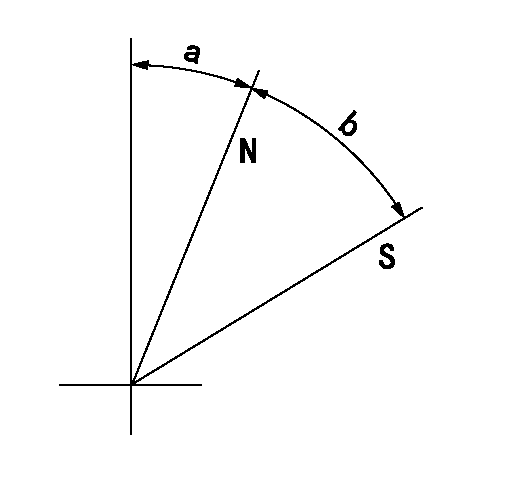

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H'

----------

----------

a=20deg+-5deg b=(39deg)+-3deg

----------

----------

a=20deg+-5deg b=(39deg)+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=25deg+-5deg b=40deg+-5deg

----------

----------

a=25deg+-5deg b=40deg+-5deg

0000001501 I/P WITH LOAD PLUNGER ADJ

Plunger assembly number: PL (stamping: ST)

1. Adjustment procedures

(1)Insert the pre-stroke adjusting shims L1 for each cylinder.

(2)Adjust injection quantity.(max. var. bet. cyl. idling a1, full a2)

(3)At basic point A, adjust so that the pre-stroke is L2.

(4)Reconfirm the injection quantity.

----------

PL=131153-4620 ST=A725 L1=1mm L2=3.7+-0.05mm a1=+-14% a2=+-2.5%

----------

----------

PL=131153-4620 ST=A725 L1=1mm L2=3.7+-0.05mm a1=+-14% a2=+-2.5%

----------

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=8.5deg

----------

a=(40deg)

----------

aa=8.5deg

----------

a=(40deg)

Information:

ACTION REQUIRED

Take the following actions after a failure occurs on one or more injectors in any of the engines in the Affected Product. A failure is considered extreme fuel dilution, in the range of 20 liters per minute.

- If one or more injectors fail it may be necessary to replace additional injectors at the time of repair.

- Verify the injector serial number of the failed injector. Verify the injector serial number of the remaining injectors in the engine. Refer to Image1 for an example of part number (A) and injector serial number identification (B). If the injector serial number falls within the range of 1134640-1234085, the injector should be replaced. The 154-6389 Buttons on the engine should also be replaced. The 154-6389 Button and 9F-7707 Retaining Clip on the injector rocker arms should also be replaced.

Only injectors falling within the range of 1134640-1234085 should be replaced and claimed under this program.

Refer to the Disassembly and Assembly manual for the removal/installation procedure of the unit injector and button.

Excessive fuel dilution of the engine oil requires changing the engine oil and filters. Refer to the appropriate Service Manual as necessary.

Image1

SERVICE CLAIM ALLOWANCES

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

*******Group 1*******

0-3000 hrs,

0-36 mo 100.0% 100.0% 0.0% 0.0% 0.0% 0.0%

This is a 2.6-hour job for Group 1

An additional 0.6 hours labor will be allowed per injector replaced due to inspection results.

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

*******Group 2*******

0-3000 hrs,

0-36 mo 100.0% 100.0% 0.0% 0.0% 0.0% 0.0%

This is a 2.6-hour job for Group 2

An additional 0.6 hours labor will be allowed per injector replaced due to inspection results.

PARTS DISPOSITION

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.