Information injection-pump assembly

BOSCH

9 400 615 163

9400615163

ZEXEL

101603-7150

1016037150

Rating:

Include in #2:

104741-1970

as _

Cross reference number

BOSCH

9 400 615 163

9400615163

ZEXEL

101603-7150

1016037150

Zexel num

Bosch num

Firm num

Name

101603-7150

9 400 615 163

INJECTION-PUMP ASSEMBLY

6SA1-T * 14BF PE6AD PE

6SA1-T * 14BF PE6AD PE

101603-7150

9 400 615 163

1156025390 ISUZU

INJECTION-PUMP ASSEMBLY

6SA1-T * 14BF PE6AD PE

6SA1-T * 14BF PE6AD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-4920

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.7

4.65

4.75

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

8.9

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

87.6

86.6

88.6

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

6+-0.5

Pump speed

r/min

325

325

325

Average injection quantity

mm3/st.

9

7

11

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Timer adjustment

Pump speed

r/min

850--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

800

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1120

Advance angle

deg.

1

0.5

1.5

Remarks

Finish

Finish

Test data Ex:

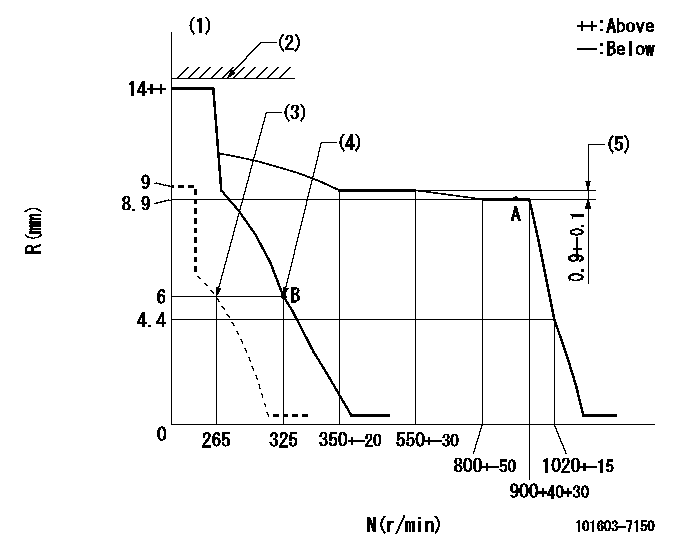

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT not operating.

(3)Set idle sub-spring

(4)Main spring setting

(5)Rack difference between N = N1 and N = N2

----------

K=7 N1=900r/min N2=500r/min

----------

----------

K=7 N1=900r/min N2=500r/min

----------

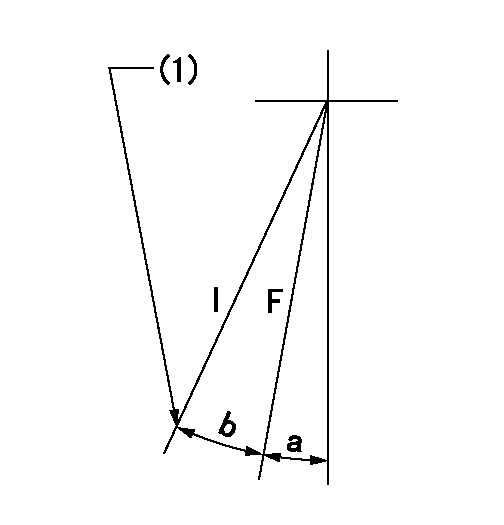

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=(1deg)+-5deg b=(19deg)+-5deg

----------

----------

a=(1deg)+-5deg b=(19deg)+-5deg

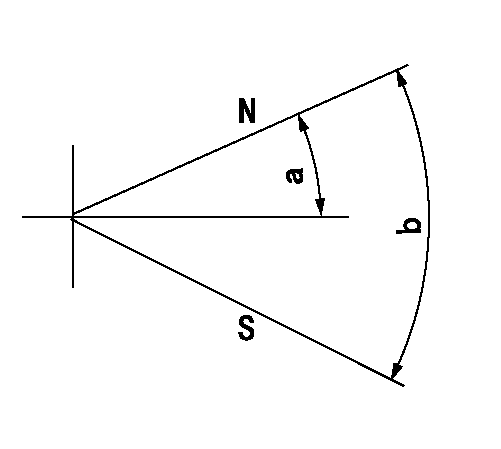

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=19deg+-5deg b=53deg+-5deg

----------

----------

a=19deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=18deg

----------

a=(40deg)

----------

aa=18deg

----------

a=(40deg)

Information:

Installation Procedure

Illustration 1 g06123834

Remove support (1) from the engine compartment.

Illustration 2 g06123840

Locate insulation (2) on the engine hood.

Illustration 3 g06123843

Raise the insulation approximately 30 mm (1.2 inch) to avoid interference with the new tank.

Illustration 4 g06123848

Loosen the worm-drive clamps and remove two hoses (3) from the DEF system. Save the cushion clamps and hardware for reuse.

Illustration 5 g06123850

(4) 428-8808 Hose Clamp

(5) 467-9633 Hose

(6) Cushion clamp (reuse)

Install hose (5) and two clamps (4). Slowly tighten the clamps to 6.6 0.2 N m (58 1.8 lb in). Install cushion clamp (6) (previously removed) onto the hose.

Illustration 6 g06123852

(4) 428-8808 Hose Clamp

(6) Cushion clamp (reuse)

(7) 469-6277 Hose

(8) 424-1209 Tank

Connect one end of hose (7) to the tube on the engine using clamp (4). Slowly tighten the clamp to 6.6 0.2 N m (58 1.8 lb in). Install cushion clamp (6) (previously removed) onto the hose.

Connect the other end of the hose to the upper port on tank (8). Install clamp (4). Slowly tighten the clamp to 6.6 0.2 N m (58 1.8 lb in).

Illustration 7 g06123862

(4) 428-8808 Hose Clamp

(9) 469-9636 Hose

(10) 6V-3250 O-Ring Seal

(11) 7X-1448 Elbow

Install elbow (11) and O-Ring seal (10) on the tank. Install hose (9) using two hose clamps (4). Slowly tighten the clamps to 6.6 0.2 N m (58 1.8 lb in) while ensuring hose (9) stays at a 30 degree angle from the top tank hose.

Illustration 8 g06123868

(12) 454-4235 Plate

(13) 326-4516 Cable Tie

Secure the two hoses together using plate (12) and two cable ties (13).

Illustration 9 g06123873

(8) 424-1209 Tank

(14) 471-9825 Support As

(15) 8T-4189 Bolt

(16) 8T-4224 Hard Washer

Install support (14) in place of the original support.

Secure tank (8) to the support using two bolts (15) and two washers (16).

Install new machine, engine, and after treatment software.The new software is available in the form of a flash file through the Caterpillar Service Information System (SIS). A newer part number may be available. SIS web only displays the latest available flash file.

Illustration 10 g06123878

Update the DES threshold to 525 degrees C using Cat® Electronic Technician (Cat ET). A factory password is required to change the value. A factory password can be obtained after inputting your Corporate Web Security (CWS) identification.

Illustration 1 g06123834

Remove support (1) from the engine compartment.

Illustration 2 g06123840

Locate insulation (2) on the engine hood.

Illustration 3 g06123843

Raise the insulation approximately 30 mm (1.2 inch) to avoid interference with the new tank.

Illustration 4 g06123848

Loosen the worm-drive clamps and remove two hoses (3) from the DEF system. Save the cushion clamps and hardware for reuse.

Illustration 5 g06123850

(4) 428-8808 Hose Clamp

(5) 467-9633 Hose

(6) Cushion clamp (reuse)

Install hose (5) and two clamps (4). Slowly tighten the clamps to 6.6 0.2 N m (58 1.8 lb in). Install cushion clamp (6) (previously removed) onto the hose.

Illustration 6 g06123852

(4) 428-8808 Hose Clamp

(6) Cushion clamp (reuse)

(7) 469-6277 Hose

(8) 424-1209 Tank

Connect one end of hose (7) to the tube on the engine using clamp (4). Slowly tighten the clamp to 6.6 0.2 N m (58 1.8 lb in). Install cushion clamp (6) (previously removed) onto the hose.

Connect the other end of the hose to the upper port on tank (8). Install clamp (4). Slowly tighten the clamp to 6.6 0.2 N m (58 1.8 lb in).

Illustration 7 g06123862

(4) 428-8808 Hose Clamp

(9) 469-9636 Hose

(10) 6V-3250 O-Ring Seal

(11) 7X-1448 Elbow

Install elbow (11) and O-Ring seal (10) on the tank. Install hose (9) using two hose clamps (4). Slowly tighten the clamps to 6.6 0.2 N m (58 1.8 lb in) while ensuring hose (9) stays at a 30 degree angle from the top tank hose.

Illustration 8 g06123868

(12) 454-4235 Plate

(13) 326-4516 Cable Tie

Secure the two hoses together using plate (12) and two cable ties (13).

Illustration 9 g06123873

(8) 424-1209 Tank

(14) 471-9825 Support As

(15) 8T-4189 Bolt

(16) 8T-4224 Hard Washer

Install support (14) in place of the original support.

Secure tank (8) to the support using two bolts (15) and two washers (16).

Install new machine, engine, and after treatment software.The new software is available in the form of a flash file through the Caterpillar Service Information System (SIS). A newer part number may be available. SIS web only displays the latest available flash file.

Illustration 10 g06123878

Update the DES threshold to 525 degrees C using Cat® Electronic Technician (Cat ET). A factory password is required to change the value. A factory password can be obtained after inputting your Corporate Web Security (CWS) identification.

Have questions with 101603-7150?

Group cross 101603-7150 ZEXEL

Isuzu

101603-7150

9 400 615 163

INJECTION-PUMP ASSEMBLY

6SA1-T

6SA1-T

Isuzu

101603-7150

9 400 615 163

1156025390

INJECTION-PUMP ASSEMBLY

6SA1-T

6SA1-T