Information injection-pump assembly

BOSCH

9 400 615 156

9400615156

ZEXEL

101603-7032

1016037032

Rating:

Service parts 101603-7032 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

1-15300-142-1

12.

Open Pre:MPa(Kqf/cm2)

18.1{185}

15.

NOZZLE SET

Include in #1:

101603-7032

as INJECTION-PUMP ASSEMBLY

Include in #2:

104741-1535

as _

Cross reference number

BOSCH

9 400 615 156

9400615156

ZEXEL

101603-7032

1016037032

Zexel num

Bosch num

Firm num

Name

101603-7032

9 400 615 156

INJECTION-PUMP ASSEMBLY

6BG1 * 14BE PE6A PE

6BG1 * 14BE PE6A PE

101603-7032

9 400 615 156

1156024832 ISUZU

INJECTION-PUMP ASSEMBLY

6BG1 * 14BE PE6A PE

6BG1 * 14BE PE6A PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-4920

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.6

3.55

3.65

Rack position

After adjusting injection quantity. R=A

After adjusting injection quantity. R=A

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

10.6

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

54.2

52.6

55.8

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

290

290

290

Average injection quantity

mm3/st.

8.4

7.1

9.7

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(10.6)

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

54.2

53.2

55.2

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1(10.6)

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

66.8

63.6

70

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

I

Rack position

-

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

87

87

119

Fixing the lever

*

Timer adjustment

Pump speed

r/min

1390--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1340

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1530

Advance angle

deg.

3.5

3

4

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

----------

T1=C78

----------

----------

T1=C78

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=35mm

----------

a=42deg+-5deg b=35deg+-3deg

----------

aa=35mm

----------

a=42deg+-5deg b=35deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Stopper bolt setting

----------

----------

a=25deg+-5deg b=40deg+-5deg

----------

----------

a=25deg+-5deg b=40deg+-5deg

0000001501 I/P WITH LOAD PLUNGER ADJ

Plunger assembly number: PL (stamping: ST)

1. Adjustment procedures

(1)Insert the pre-stroke adjusting shims L1 for each cylinder.

(2)Adjust injection quantity.(max. var. bet. cyl. idling a1, full a2)

(3)At basic point A, adjust so that the pre-stroke is L2.

(4)Reconfirm the injection quantity.

----------

PL=131154-2520 ST=A267 L1=1mm L2=3.6+-0.05mm a1=+-14% a2=+-2.5%

----------

----------

PL=131154-2520 ST=A267 L1=1mm L2=3.6+-0.05mm a1=+-14% a2=+-2.5%

----------

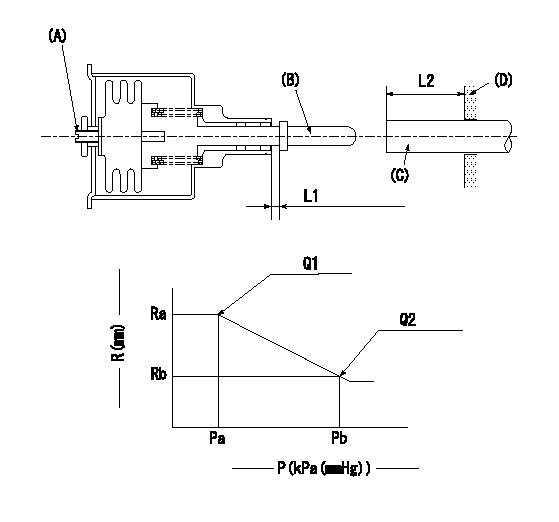

0000001601 ACS

(A) Set screw

(B) Push rod 1

(C) Push rod 2

(D) Cover

1. Aneroid compensator unit adjustment

(1)Select the push rod 2 to obtain L2.

(2)Screw in (A) to obtain L1.

2. Adjustment when mounting the governor.

(1)Set the speed of the pump to N1 r/min and fix the control lever at the full set position.

(2)Screw in the aneroid compensator to obtain the performance shown in the graph above.

(3)As there is hysterisis, measure when the absolute pressure drops.

(4)Hysterisis must not exceed rack position = h1.

----------

N1=900r/min L1=(1.5)mm L2=11+-0.5mm h1=0.15mm

----------

Ra=R1(10.6)mm Rb=R1-0.5mm Pa=84.5+-2.7kPa(634+-20mmHg) Pb=70.1+-0.7kPa(526+-5mmHg) Q1=54.2+-1cm3/1000st Q2=(39.8)+-1.6cm3/1000st

----------

N1=900r/min L1=(1.5)mm L2=11+-0.5mm h1=0.15mm

----------

Ra=R1(10.6)mm Rb=R1-0.5mm Pa=84.5+-2.7kPa(634+-20mmHg) Pb=70.1+-0.7kPa(526+-5mmHg) Q1=54.2+-1cm3/1000st Q2=(39.8)+-1.6cm3/1000st

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=12deg

----------

a=(60deg)

----------

aa=12deg

----------

a=(60deg)

Information:

REM02-13

Reman

May 2002 RELOCATION OF SERVICE CENTER FOR 3600 FUEL INJECTORS Announcement Caterpillar is pleased to announce the relocation of the 3600 Fuel Injector Service Center from Booneville, MS to Caterpillar?s Fuel Injector Remanufacturing facility located in Nuevo Laredo, Mexico effective June 01, 2002. This Service Center provides a 3600 Fuel Injector ?Repair and Return? service, principally for dealers in North and South America. This move will in no way effect the excellent service Dealers have come to expect from this program. Injectors in transit to the Boonville, MS facility will be redirected to the Nuevo Laredo facility.Program Dealers can continue to send their 3600 injectors, tagged with Caterpillar? form number 00040279-00 directly to the new address listed below. New forms are being printed with a corrected ship to address. In the interim, Dealers should continue to use the old form. The Dealer will continue to be responsible for freight and insurance to and from the Service Center. The Center will, as in the past, service the injectors and return them, along with an individual certificate of conformity, to wherever the dealer requires. A database with key information on each injector will continue be maintained at the Service Center.The injectors will receive an initial inspection within five days of receipt. Normal turnaround time for the repaired injectors will be 20 ? 30 days. However, should the injectors be required urgently, this can be specified as a special instruction on the shipping tag and accommodated with a premium charge. Special return shipping instructions, such as airfreight, should also be communicated on the shipping tag. If not specified, the repaired injectors will be returned via standard surface freight to the dealer?s main office address.Shipping Location

Caterpillar Inc.

C/O Tecmosa/Dicex International

1101 Black Diamond

International Commerce Center

Laredo, TX 78045

Attn: 3600 Injector Service Center

The new Service Center Customer Service telephone number is: 1877-536-5460.

Features And BenefitsThe service provided will be a ?repair and return? service of the customer?s serialized injector, as opposed to a Reman exchange for a customer?s core. The customer will get his own injector back. It will have been completely disassembled with each component inspected, and after re-assembly, 100% tested against new specifications. A technical report will be completed and returned with each injector to help the dealer analyze any fuel system related problems, which if corrected could possibly help extend the life of the injectors.This service does not replace the remanufactured injector program. It complements it as another repair option offered at a price comparable to the competition. The dealer may choose to have the injectors cleaned or repaired. Or, depending on the need, a remanufactured injector can still be purchased. In this case the Service Center will notify the dealer and transfer the core to Reman, establishing a core credit for the dealer. This Service Center will provide one more way to lower the customer?s owning and operating expenses.Price A flat labor charge of $200 US plus any new components replaced will be

Have questions with 101603-7032?

Group cross 101603-7032 ZEXEL

Isuzu

Isuzu

101603-7032

9 400 615 156

INJECTION-PUMP ASSEMBLY

6BG1

6BG1

Isuzu

101603-7032

9 400 615 156

1156024832

INJECTION-PUMP ASSEMBLY

6BG1

6BG1