Information injection-pump assembly

BOSCH

9 400 615 155

9400615155

ZEXEL

101603-7022

1016037022

ISUZU

1156024822

1156024822

Rating:

Service parts 101603-7022 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

1-15300-142-1

12.

Open Pre:MPa(Kqf/cm2)

18.1{185}

15.

NOZZLE SET

Include in #1:

101603-7022

as INJECTION-PUMP ASSEMBLY

Include in #2:

104741-1515

as _

Cross reference number

BOSCH

9 400 615 155

9400615155

ZEXEL

101603-7022

1016037022

ISUZU

1156024822

1156024822

Zexel num

Bosch num

Firm num

Name

101603-7022

9 400 615 155

1156024822 ISUZU

INJECTION-PUMP ASSEMBLY

6BG1 K 14BE INJECTION PUMP ASSY PE6A PE

6BG1 K 14BE INJECTION PUMP ASSY PE6A PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-4920

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.6

3.55

3.65

Rack position

After adjusting injection quantity. R=A

After adjusting injection quantity. R=A

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

10.6

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

54.2

52.6

55.8

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

290

290

290

Average injection quantity

mm3/st.

8.4

7.1

9.7

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(10.6)

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

54.2

53.2

55.2

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1(10.6)

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

66.8

63.6

70

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

I

Rack position

-

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

87

87

119

Fixing the lever

*

Timer adjustment

Pump speed

r/min

1390--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1340

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1530

Advance angle

deg.

3.5

3

4

Remarks

Finish

Finish

Test data Ex:

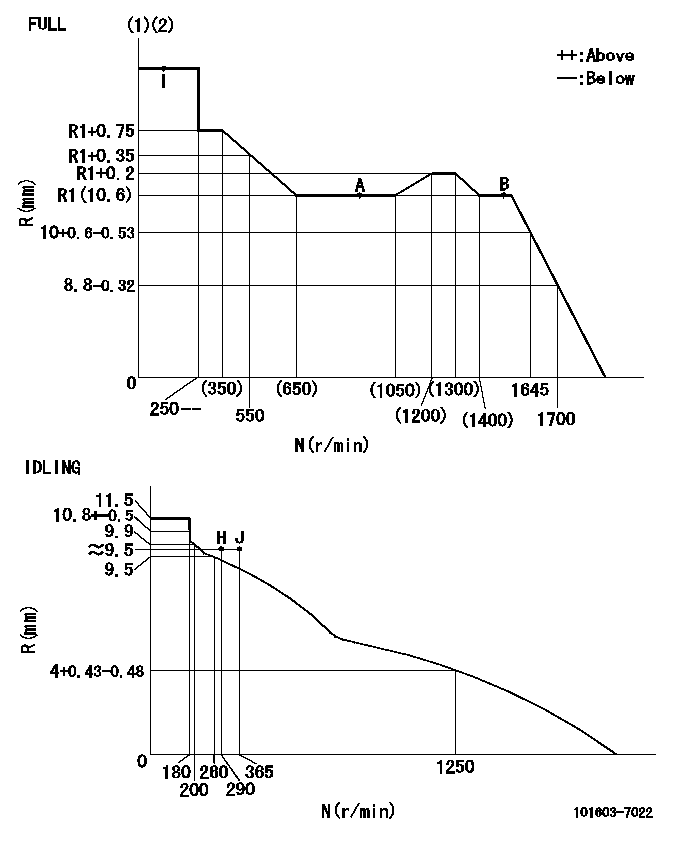

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

----------

T1=C78

----------

----------

T1=C78

----------

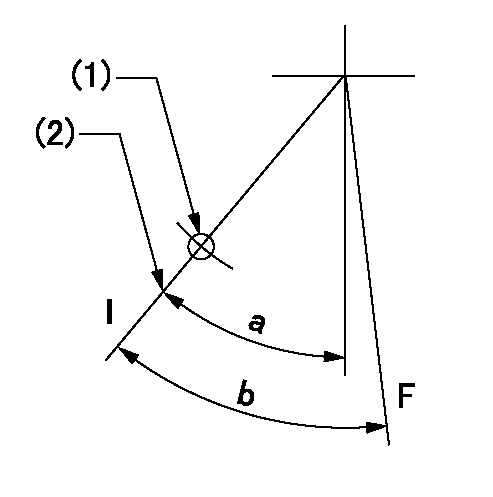

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=35mm

----------

a=34deg+-5deg b=35deg+-3deg

----------

aa=35mm

----------

a=34deg+-5deg b=35deg+-3deg

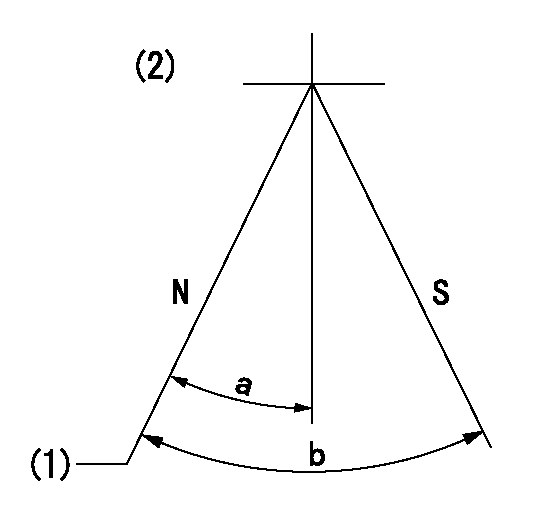

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Stopper bolt setting

(2)Upper lever angle

----------

----------

a=25deg+-5deg b=40deg+-5deg

----------

----------

a=25deg+-5deg b=40deg+-5deg

0000001501 I/P WITH LOAD PLUNGER ADJ

Plunger assembly number: PL (stamping: ST)

1. Adjustment procedures

(1)Insert the pre-stroke adjusting shims L1 for each cylinder.

(2)Adjust injection quantity.(max. var. bet. cyl. idling a1, full a2)

(3)At basic point A, adjust so that the pre-stroke is L2.

(4)Reconfirm the injection quantity.

----------

PL=131154-2520 ST=A267 L1=1mm L2=3.6+-0.05mm a1=+-14% a2=+-2.5%

----------

----------

PL=131154-2520 ST=A267 L1=1mm L2=3.6+-0.05mm a1=+-14% a2=+-2.5%

----------

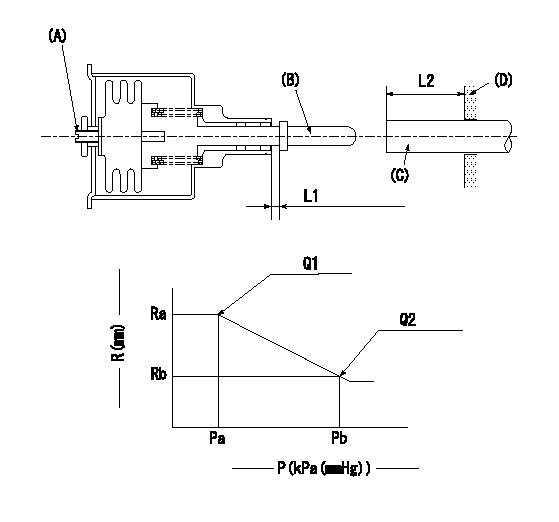

0000001601 ACS

(A) Set screw

(B) Push rod 1

(C) Push rod 2

(D) Cover

1. Aneroid compensator unit adjustment

(1)Select the push rod 2 to obtain L2.

(2)Screw in (A) to obtain L1.

2. Adjustment when mounting the governor.

(1)Set the speed of the pump to N1 r/min and fix the control lever at the full set position.

(2)Screw in the aneroid compensator to obtain the performance shown in the graph above.

(3)As there is hysterisis, measure when the absolute pressure drops.

(4)Hysterisis must not exceed rack position = h1.

----------

N1=900r/min L1=(1.5)mm L2=11+-0.5mm h1=0.15mm

----------

Ra=R1(10.6)mm Rb=R1-0.5mm Pa=84.5+-2.7kPa(634+-20mmHg) Pb=70.1+-0.7kPa(526+-5mmHg) Q1=54.2+-1cm3/1000st Q2=(39.8)+-1.6cm3/1000st

----------

N1=900r/min L1=(1.5)mm L2=11+-0.5mm h1=0.15mm

----------

Ra=R1(10.6)mm Rb=R1-0.5mm Pa=84.5+-2.7kPa(634+-20mmHg) Pb=70.1+-0.7kPa(526+-5mmHg) Q1=54.2+-1cm3/1000st Q2=(39.8)+-1.6cm3/1000st

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=12deg

----------

a=(60deg)

----------

aa=12deg

----------

a=(60deg)

Information:

Introduction

Injector height setting is extremely important during the engine assembly process. The recommended intervals that are specified in the Operation and Maintenance Manual must be followed.Problem

An issue has been identified with the correct injector height settings. Check the injector height. Bottoming of the fuel injector rocker arm may be caused by the injector height being to high or low. Bottoming of the fuel injector can create a crack at the nose of the fuel injector rocker arm through the first and second threads of the adjusting screw hole. Once the crack has started it can result in the breaking of the fuel injector rocker arm at the nose. Breaking of the fuel injector rocker arm will result in an immediate poor engine performance.Solution

Performing the recommended inspection of the fuel injector rocker arm at the specified intervals in the operation and maintenance manual is important. Inspect the height

Injector height setting is extremely important during the engine assembly process. The recommended intervals that are specified in the Operation and Maintenance Manual must be followed.Problem

An issue has been identified with the correct injector height settings. Check the injector height. Bottoming of the fuel injector rocker arm may be caused by the injector height being to high or low. Bottoming of the fuel injector can create a crack at the nose of the fuel injector rocker arm through the first and second threads of the adjusting screw hole. Once the crack has started it can result in the breaking of the fuel injector rocker arm at the nose. Breaking of the fuel injector rocker arm will result in an immediate poor engine performance.Solution

Performing the recommended inspection of the fuel injector rocker arm at the specified intervals in the operation and maintenance manual is important. Inspect the height

Have questions with 101603-7022?

Group cross 101603-7022 ZEXEL

Isuzu

Isuzu

101603-7022

9 400 615 155

1156024822

INJECTION-PUMP ASSEMBLY

6BG1

6BG1