Information injection-pump assembly

BOSCH

9 400 615 141

9400615141

ZEXEL

101603-6690

1016036690

MITSUBISHI

ME059795

me059795

Rating:

Service parts 101603-6690 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

21.6(220)

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 615 141

9400615141

ZEXEL

101603-6690

1016036690

MITSUBISHI

ME059795

me059795

Zexel num

Bosch num

Firm num

Name

101603-6690

9 400 615 141

ME059795 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D22 K 14BF INJECTION PUMP ASSY PE6AD PE

6D22 K 14BF INJECTION PUMP ASSY PE6AD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5120

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.5

4.45

4.55

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

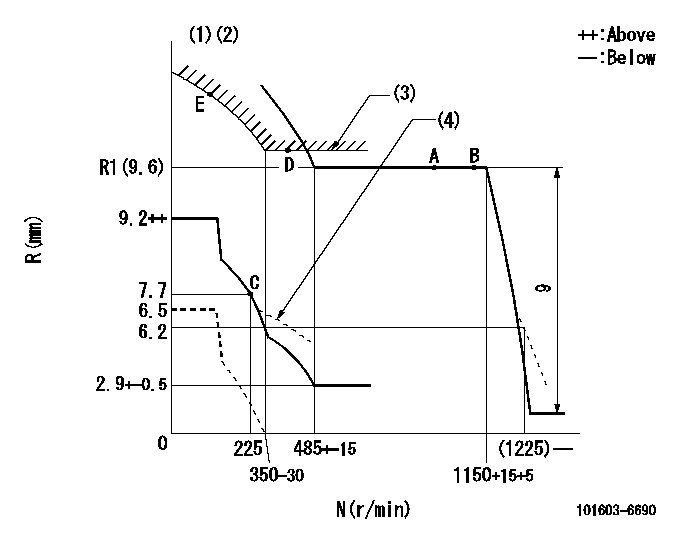

Injection quantity adjustment

Adjusting point

-

Rack position

9.6

Pump speed

r/min

700

700

700

Each cylinder's injection qty

mm3/st.

112

108.6

115.4

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

7.7+-0.5

Pump speed

r/min

225

225

225

Each cylinder's injection qty

mm3/st.

18.5

15.7

21.3

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(9.6)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

112

111

113

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1(9.6)

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

112

109.5

114.5

Difference in delivery

mm3/st.

9

9

9

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

E

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

170

130

210

Fixing the lever

*

Remarks

After startup boost setting

After startup boost setting

Timer adjustment

Pump speed

r/min

850--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

800

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

900

Advance angle

deg.

0.9

0.4

1.4

Timer adjustment_04

Pump speed

r/min

1150

Advance angle

deg.

3

2.5

3.5

Timer adjustment_05

Pump speed

r/min

-

Advance angle

deg.

4

3

5

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)Excess fuel setting for starting: SXL

(4)Damper spring setting: DL

----------

RT=1 TH=2.9mm SXL=11.6+-0.1mm DL=6.7-0.2mm

----------

----------

RT=1 TH=2.9mm SXL=11.6+-0.1mm DL=6.7-0.2mm

----------

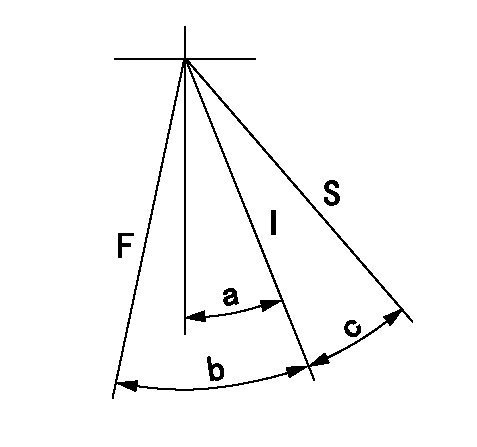

Speed control lever angle

F:Full speed

----------

----------

a=4deg+-5deg

----------

----------

a=4deg+-5deg

0000000901

F:Full load

I:Idle

S:Stop

----------

----------

a=21deg+-5deg b=24.5deg+-3deg c=13deg+-3deg

----------

----------

a=21deg+-5deg b=24.5deg+-3deg c=13deg+-3deg

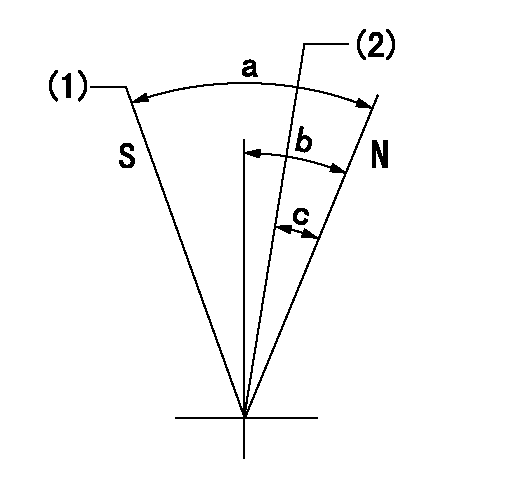

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

(2)Rack position bb

----------

aa=2.5mm bb=21mm

----------

a=71deg+-5deg b=12deg+-5deg c=(9.5deg)

----------

aa=2.5mm bb=21mm

----------

a=71deg+-5deg b=12deg+-5deg c=(9.5deg)

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=325+-5r/min Ra=7mm

----------

----------

N1=325+-5r/min Ra=7mm

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(7deg)

----------

----------

a=(7deg)

Information:

CLEANING ELEMENT WITH AIRCLEANING WITH WATER: Using clean water, at a pressure not to exceed 40 PSI, proceed as follows:Direct water at an angle against the inside (engine side) of the element to loosen any imbedded dirt. Best results can be obtained by using a water hose without a nozzle and moving it so that water is directed at an angle along the complete length of each pleat. Wash off loose dirt by directing water against the outside of the element. Repeat this procedure until the element is clean. Make certain that no dirt is on the engine side of the element, and thoroughly dry the element before installing it.

CLEANING ELEMENT WITH WATERCLEANING WITH DETERGENT: Some oily and/or sooty deposits can be removed by washing the element in a solution of warm water and a good household non-sudsing detergent. Rinse with clean water and thoroughly dry the element before installing it.

WASHING ELEMENT WITH DETERGENTINSPECTING ELEMENT:1. Hold a lighted electric bulb inside the dried element and carefully inspect the element for tiny, pinpoints of light. Any light showing indicates a pleat has ruptured and will tear with further use. Discard the element.2. Wrap usable elements in sealed plastic bags.3. Store the wrapped element in a dry, clean place.

INSPECTING ELEMENTWhen equipped with oil bath type air cleaners, accumulation of dirt and/or oil in the air cleaner outlet pipe is an indication the air cleaner is not being serviced or functioning properly. Refer to manufacturer's recommendations for servicing.Valve Lash Setting

Check Valve Lash Setting With Engine Stopped:1. Remove the flywheel timing cover from the flywheel housing. Rotate the engine flywheel in direction of engine rotation, so the flywheel timing pointer is at the TC 1-6 cyl. mark on the flywheel. Remove the bolt from the flywheel timing hole and insert timing bolt (long bolt which fastens cover to flywheel). 2. Remove the valve cover and observe the positions of the No. 1 and No. 6 cylinder valves and the camshaft lobes to determine which cylinder is sealed for compression.3. Turn adjusting screw counterclockwise 2 clicks or more to provide clearance between rocker assembly and valve.4. Turn adjusting screw clockwise to obtain zero lash. There should be no free rocker movement or adjusting screw button lateral movement.

VALVE ADJUSTMENT The adjusting screw button can still be rotated by finger pressure even when it is in contact with valve stem and clearance is zero. Turning the adjusting screw clockwise beyond this point will force the valve off its seat, and final lash setting will be incorrect.

VALVE CLEARANCE SETTINGS5. Turn adjustment screw counterclockwise ten clicks (.020 in.; 0,50 mm) for exhaust valves and four clicks (.008 in.; 0,20 mm) for inlet valves. One click is equal to .002 in. (0,050 mm). All exhaust and inlet valve clearance can be adjusted by positioning the flywheel only twice. After adjusting half of the valves, rotate the engine 360° in direction of normal rotation and adjust the remaining half. If No. 1 cylinder is in compression, adjust the inlet

Have questions with 101603-6690?

Group cross 101603-6690 ZEXEL

Mitsubishi

101603-6690

9 400 615 141

ME059795

INJECTION-PUMP ASSEMBLY

6D22

6D22