Information injection-pump assembly

BOSCH

9 400 615 120

9400615120

ZEXEL

101603-6311

1016036311

MITSUBISHI

ME035599

me035599

Rating:

Service parts 101603-6311 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

ME035749

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 615 120

9400615120

ZEXEL

101603-6311

1016036311

MITSUBISHI

ME035599

me035599

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5520

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3

2.95

3.05

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

12.1

Pump speed

r/min

800

800

800

Each cylinder's injection qty

mm3/st.

88

85.4

90.6

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

275

275

275

Each cylinder's injection qty

mm3/st.

10.5

9

12

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(12.1)

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

88

87

89

Basic

*

Fixing the lever

*

Boost pressure

kPa

49.3

49.3

Boost pressure

mmHg

370

370

Injection quantity adjustment_04

Adjusting point

C

Rack position

(R1-0.8)

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

67

65

69

Fixing the lever

*

Boost pressure

kPa

18.7

18.7

18.7

Boost pressure

mmHg

140

140

140

Injection quantity adjustment_05

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

110

90

130

Fixing the lever

*

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

700

700

700

Rack position

R1-1.1

Boost pressure

kPa

13.3

13.3

13.3

Boost pressure

mmHg

100

100

100

Boost compensator adjustment_02

Pump speed

r/min

700

700

700

Rack position

(R1-0.8)

Boost pressure

kPa

18.7

17.4

20

Boost pressure

mmHg

140

130

150

Boost compensator adjustment_03

Pump speed

r/min

700

700

700

Rack position

R1(12.1)

Boost pressure

kPa

36

29.3

42.7

Boost pressure

mmHg

270

220

320

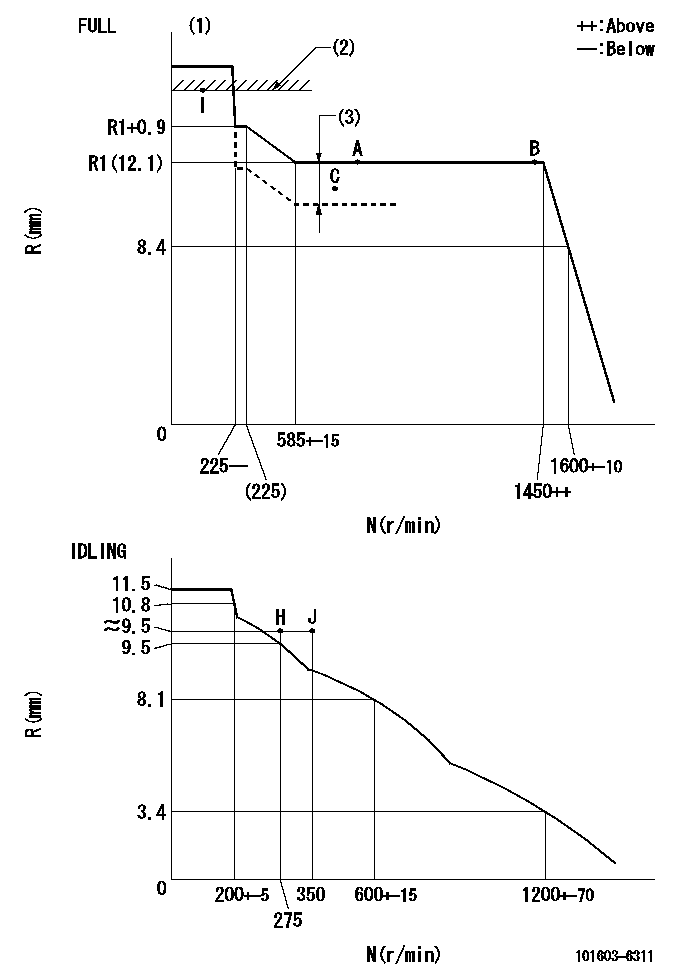

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)RACK LIMIT

(3)Boost compensator stroke: BCL

----------

T1=B44 BCL=1.1+-0.1mm

----------

----------

T1=B44 BCL=1.1+-0.1mm

----------

Timer adjustment

(1)Adjusting range

(2)Step response time

(N): Speed of the pump

(L): Load

(theta) Advance angle

(Srd1) Step response time 1

(Srd2) Step response time 2

1. Adjusting conditions for the variable timer

(1)Adjust the clearance between the pickup and the protrusion to L.

----------

L=1.5+-0.2mm N2=800r/min C3=(8deg) t1=2--sec. t2=2--sec.

----------

N1=1400r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=0.5--deg C2=8+-0.3deg R01=0/4load R02=4/4load

----------

L=1.5+-0.2mm N2=800r/min C3=(8deg) t1=2--sec. t2=2--sec.

----------

N1=1400r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=0.5--deg C2=8+-0.3deg R01=0/4load R02=4/4load

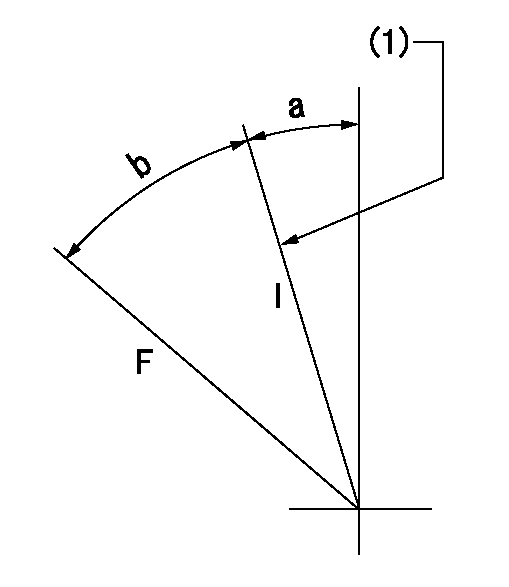

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H'

----------

----------

a=18.5deg+-5deg b=(41deg)+-3deg

----------

----------

a=18.5deg+-5deg b=(41deg)+-3deg

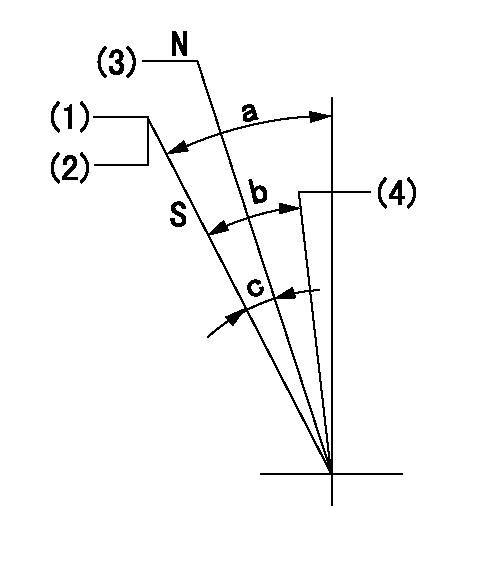

Stop lever angle

N:Engine manufacturer's normal use

S:Stop the pump.

(1)Set the stopper bolt at speed = rated point and rack position = aa (non-injection rack position). Confirm non-injection.

(2)After setting the stopper bolt , confirm non-injection at pump speed bb. Rack position = cc (non-injection rack position).

(3)Rack position = approximately dd

(4)Free (at shipping)

----------

aa=(7.5)mm bb=275r/min cc=(9)mm dd=17.4mm

----------

a=38.5deg+-5deg b=(27deg) c=17deg+-5deg

----------

aa=(7.5)mm bb=275r/min cc=(9)mm dd=17.4mm

----------

a=38.5deg+-5deg b=(27deg) c=17deg+-5deg

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=400+-5r/min Ra=9.2mm

----------

----------

N1=400+-5r/min Ra=9.2mm

----------

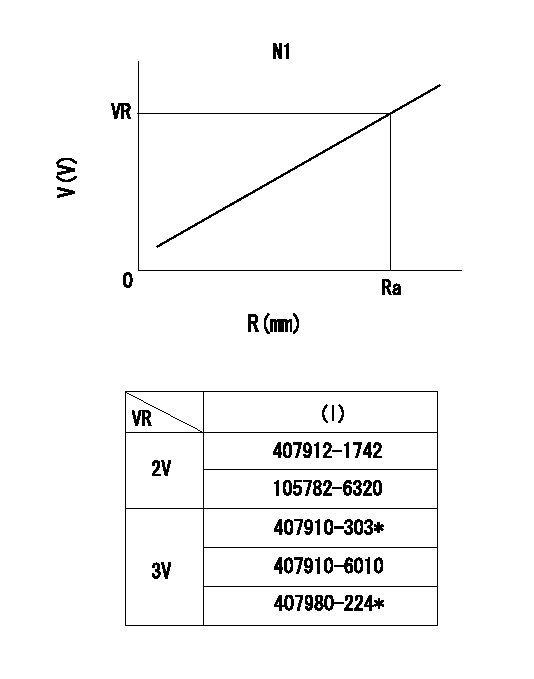

0000001601 RACK SENSOR

R:Rack position (mm)

V:Voltage (V)

After installing the rack sensor, confirm the output value (VR).

----------

N1=- Ra=R1(12.1)mm VR=1.99+-0.01V

----------

----------

N1=- Ra=R1(12.1)mm VR=1.99+-0.01V

----------

Timing setting

(1)Pump vertical direction

(2)Position of timer's tooth at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=14deg

----------

a=(0deg)

----------

aa=14deg

----------

a=(0deg)

Information:

Illustration 17 g03389921

Illustration 18 g03389931

Read the warning and select "Accept" to continue.

Illustration 19 g03389947

Once the reset is completed, a log of the reset is captured and visible as a new row of information in the Diesel Oxidation Catalyst Replacement screen. Selective Catalytic Reduction (SCR) Maintenance on Tier 4 Final Products

Note: Refer to Table 5 for the existing SCR catalyst part number being serviced along with the corresponding new service kit, and the clamp part number required for reassembly.

Table 5

SCR Part Number Service Kit Part Number Required Clamp Part Number

447-8145 N/A 346-0335

447-8143 N/A 346-0335

447-8141 N/A 346-0335

447-8149 N/A 346-0335

447-8147 N/A 346-0335

447-8163 N/A 346-0335

447-8151 N/A 346-0335

375-0989 N/A 346-0335

447-8165 N/A 346-0335

447-8153 N/A 346-0335

447-8161 N/A 346-0335

447-8159 N/A 346-0335

447-8157 N/A 346-0335

447-8169 N/A 346-0335

447-8173 N/A 346-0335

447-8171 N/A 346-0335

447-8167 N/A 346-0335

447-8175 N/A 346-0335 The Aftertreatment SCR Catalyst Replacement procedure must be performed when the SCR Catalyst has been replaced. This is necessary to ensure that the engine meets emissions requirements. Follow the procedure below to reset the SCR Catalyst model in the aftertreatment software.

Connect to Cat® ET.

Illustration 20 g03390636

Connect to "Engine #1 Aftertreatment Controller".

Illustration 21 g03740190

Select "Service" from the top menu and select "Service Procedures".

Illustration 22 g03740205

Select "Aftertreatment #1 SCR Catalyst Replacement" and select "Start".

Illustration 23 g03740210

Select "Reset".

Illustration 24 g03740216

You must read the warning and select "Accept" to continue.

Enter the factory passwords to continue.

Illustration 25 g03740230

Once the reset is completed, a log of the reset is captured and visible as a new row of information in the "Aftertreatment #1 SCR Catalyst Replacement" screen.