Information injection-pump assembly

ZEXEL

101603-6170

1016036170

MITSUBISHI

ME035584

me035584

Rating:

Cross reference number

ZEXEL

101603-6170

1016036170

MITSUBISHI

ME035584

me035584

Zexel num

Bosch num

Firm num

Name

101603-6170

ME035584 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D15 * K

6D15 * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5520

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

11

Pump speed

r/min

850

850

850

Each cylinder's injection qty

mm3/st.

60

58.1

61.9

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

10+-0.5

Pump speed

r/min

275

275

275

Each cylinder's injection qty

mm3/st.

10

8.9

11.1

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11)

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

60

59

61

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.4

Pump speed

r/min

1450

1450

1450

Average injection quantity

mm3/st.

76.5

72.5

80.5

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

E

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

70

30

110

Fixing the lever

*

Remarks

After startup boost setting

After startup boost setting

Timer adjustment

Pump speed

r/min

1250--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1200

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1350

Advance angle

deg.

2.4

1.9

2.9

Timer adjustment_04

Pump speed

r/min

1500

Advance angle

deg.

5

4.5

5.5

Remarks

Finish

Finish

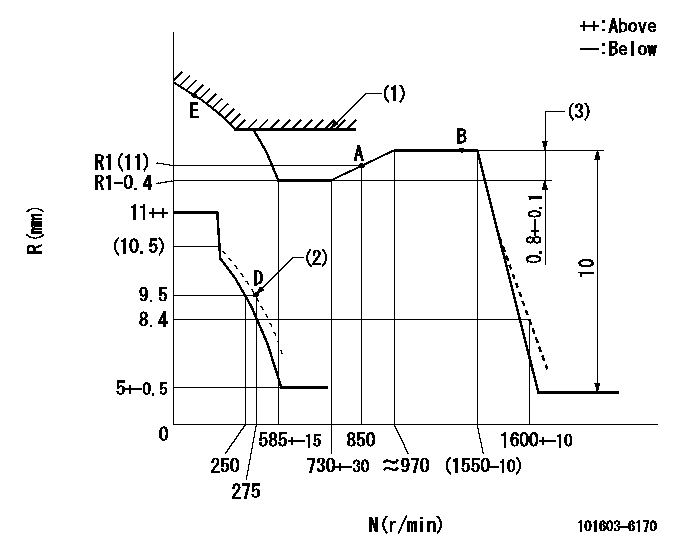

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Excess fuel setting for starting: SXL

(2)Damper spring setting

(3)Rack difference between N = N1 and N = N2

----------

SXL=R1(11)+2+1.8mm N1=1450r/min N2=600r/min

----------

----------

SXL=R1(11)+2+1.8mm N1=1450r/min N2=600r/min

----------

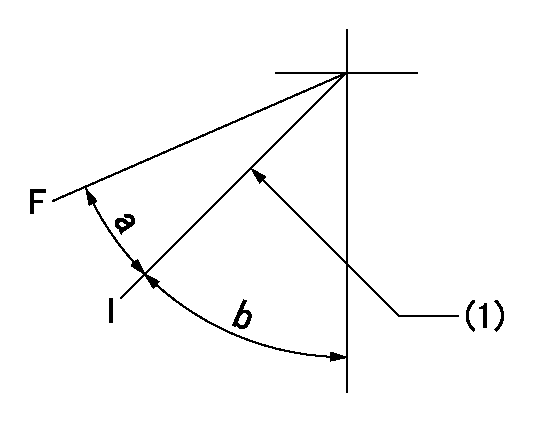

Speed control lever angle

F:Full speed

----------

----------

a=13deg+-5deg

----------

----------

a=13deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=20.5deg+-3deg b=30deg+-5deg

----------

----------

a=20.5deg+-3deg b=30deg+-5deg

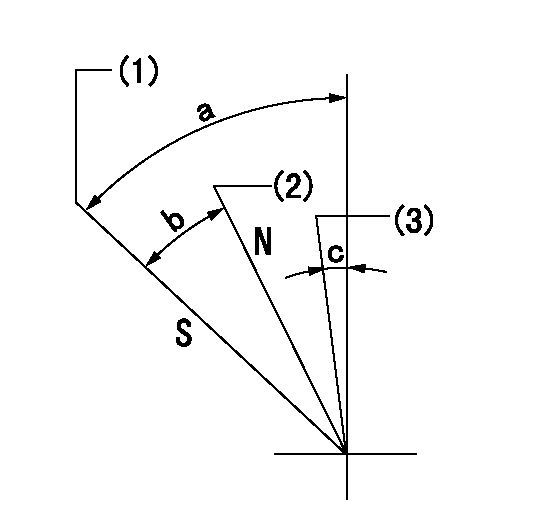

Stop lever angle

N:Engine manufacturer's normal use

S:Stop the pump.

(1)Rack position = aa

(2)Rack position bb

(3)Free (at shipping)

----------

aa=7-0.5mm bb=13.5mm

----------

a=55.5deg+7deg-5deg b=21.5deg+-5deg c=(1deg)

----------

aa=7-0.5mm bb=13.5mm

----------

a=55.5deg+7deg-5deg b=21.5deg+-5deg c=(1deg)

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=400+-5r/min Ra=9.2mm

----------

----------

N1=400+-5r/min Ra=9.2mm

----------

Timing setting

(1)Pump vertical direction

(2)Position of timer's tooth at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=12deg

----------

a=(1deg)

----------

aa=12deg

----------

a=(1deg)

Information:

Introduction

This Special Instruction provides information in order to prolong the life of the cutting bits on the PM-465 rotor. An additional spray nozzle was added to the left side of the chamber.Rework Procedure

Table 1

Required Parts

Quantity Part Number Description

1 211-8607 Tube

1 211-8604 Plate

1 1G-6699 Adapter

1 1G-8270 Nozzle Body

2 5D-1026 Hose Clamp

1000 mm (39 inch) 5P-1690 Hose

1 081-2963 Cap

1 081-2965 Seal

1 115-9969 Male Connector

1 115-9970 Male Connector

1 212-0911 Nozzle

Illustration 1 g00853436

(A) 573 mm (22.56 inches) (B) 102.5 mm (4 inches) (C) 150 mm (5.91 inches)

Remove 142-7461 Plate (1) from the chamber.

Relocate the 142-7461 Plate (1) .

The new location of the 142-7461 Plate (1) should measure 150 mm (5.91 inches) (C) from the top of the chamber. The center of the 142-7461 Plate should remain at 573 mm (22.56 inches) (A) .

Cut a slot in the left side of the chamber that is 40 mm (1.57 inch) by 85 mm (3.35 inch). The center of the slot should measure 102.5 mm (4 inches) from the top (B) of the chamber and 573 mm (22.56 inches) from the front (A) of the chamber. Refer to Illustration 1.

Illustration 2 g00853889

Weld the 211-8604 Plate (2) in the slot. The plate should be flush with the inside of the chamber. Face the open end of the plate downward in the slot.

Illustration 3 g00853468

Illustration 4 g00853890

(D) 20 mm (0.79 inch) (E) 8.5 mm (0.33 inch)

Weld a 211-8607 Tube (3) onto the side of the chamber. Position the bottom of the tube 20 mm (0.79 inch) (D) from the bottom of the slot and 8.5 mm (0.33 inch) (E) to the right of the slot. Refer to Illustration 4.

Illustration 5 g00853470

Remove hose assembly (4) from the nozzle (5) that is located near the left side of the chamber.

Replace connector (6) with 115-9970 Male Connector .

Illustration 6 g00863254

Use the following parts in order to assemble a new nozzle: 115-9969 Male Connector (7), 1G-6699 Adapter (8), 1G-8270 Nozzle Body (9), 212-0911 Nozzle (10), 081-2965 Seal (11) and 081-2963 Cap (12) .

Illustration 7 g00853509

Place the new nozzle assembly in tube (13) that is located on the side of the chamber.Note: The flat spray pattern of the nozzle should be parallel to the slot.

Connect the two nozzles with a 5P-1690 Hose . Use two 5D-1026 Hose Clamps in order to secure the hose to the nozzles.

This Special Instruction provides information in order to prolong the life of the cutting bits on the PM-465 rotor. An additional spray nozzle was added to the left side of the chamber.Rework Procedure

Table 1

Required Parts

Quantity Part Number Description

1 211-8607 Tube

1 211-8604 Plate

1 1G-6699 Adapter

1 1G-8270 Nozzle Body

2 5D-1026 Hose Clamp

1000 mm (39 inch) 5P-1690 Hose

1 081-2963 Cap

1 081-2965 Seal

1 115-9969 Male Connector

1 115-9970 Male Connector

1 212-0911 Nozzle

Illustration 1 g00853436

(A) 573 mm (22.56 inches) (B) 102.5 mm (4 inches) (C) 150 mm (5.91 inches)

Remove 142-7461 Plate (1) from the chamber.

Relocate the 142-7461 Plate (1) .

The new location of the 142-7461 Plate (1) should measure 150 mm (5.91 inches) (C) from the top of the chamber. The center of the 142-7461 Plate should remain at 573 mm (22.56 inches) (A) .

Cut a slot in the left side of the chamber that is 40 mm (1.57 inch) by 85 mm (3.35 inch). The center of the slot should measure 102.5 mm (4 inches) from the top (B) of the chamber and 573 mm (22.56 inches) from the front (A) of the chamber. Refer to Illustration 1.

Illustration 2 g00853889

Weld the 211-8604 Plate (2) in the slot. The plate should be flush with the inside of the chamber. Face the open end of the plate downward in the slot.

Illustration 3 g00853468

Illustration 4 g00853890

(D) 20 mm (0.79 inch) (E) 8.5 mm (0.33 inch)

Weld a 211-8607 Tube (3) onto the side of the chamber. Position the bottom of the tube 20 mm (0.79 inch) (D) from the bottom of the slot and 8.5 mm (0.33 inch) (E) to the right of the slot. Refer to Illustration 4.

Illustration 5 g00853470

Remove hose assembly (4) from the nozzle (5) that is located near the left side of the chamber.

Replace connector (6) with 115-9970 Male Connector .

Illustration 6 g00863254

Use the following parts in order to assemble a new nozzle: 115-9969 Male Connector (7), 1G-6699 Adapter (8), 1G-8270 Nozzle Body (9), 212-0911 Nozzle (10), 081-2965 Seal (11) and 081-2963 Cap (12) .

Illustration 7 g00853509

Place the new nozzle assembly in tube (13) that is located on the side of the chamber.Note: The flat spray pattern of the nozzle should be parallel to the slot.

Connect the two nozzles with a 5P-1690 Hose . Use two 5D-1026 Hose Clamps in order to secure the hose to the nozzles.

Have questions with 101603-6170?

Group cross 101603-6170 ZEXEL

Mitsubishi

101603-6170

ME035584

INJECTION-PUMP ASSEMBLY

6D15

6D15