Information injection-pump assembly

BOSCH

9 400 615 113

9400615113

ZEXEL

101603-6150

1016036150

MITSUBISHI

ME032909

me032909

Rating:

Service parts 101603-6150 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

10.

NOZZLE AND HOLDER ASSY

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

13.

NOZZLE-HOLDER

14.

NOZZLE

15.

NOZZLE SET

Include in #1:

101603-6150

as INJECTION-PUMP ASSEMBLY

Include in #2:

104748-1713

as _

Cross reference number

BOSCH

9 400 615 113

9400615113

ZEXEL

101603-6150

1016036150

MITSUBISHI

ME032909

me032909

Zexel num

Bosch num

Firm num

Name

101603-6150

9 400 615 113

ME032909 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D15 K 14BE INJECTION PUMP ASSY PE6A PE

6D15 K 14BE INJECTION PUMP ASSY PE6A PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-3720

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.3

3.25

3.35

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

11.5

Pump speed

r/min

850

850

850

Each cylinder's injection qty

mm3/st.

61.5

59.7

63.3

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

9.7+-0.5

Pump speed

r/min

275

275

275

Each cylinder's injection qty

mm3/st.

10.5

9

12

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.5)

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

61.5

60.5

62.5

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1(11.5)

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

65.8

63.1

68.5

Difference in delivery

mm3/st.

5.4

5.4

5.4

Fixing the lever

*

Timer adjustment

Pump speed

r/min

850+-50

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1200

Advance angle

deg.

2.6

2.1

3.1

Timer adjustment_03

Pump speed

r/min

1500

Advance angle

deg.

5.5

5

6

Remarks

Finish

Finish

Test data Ex:

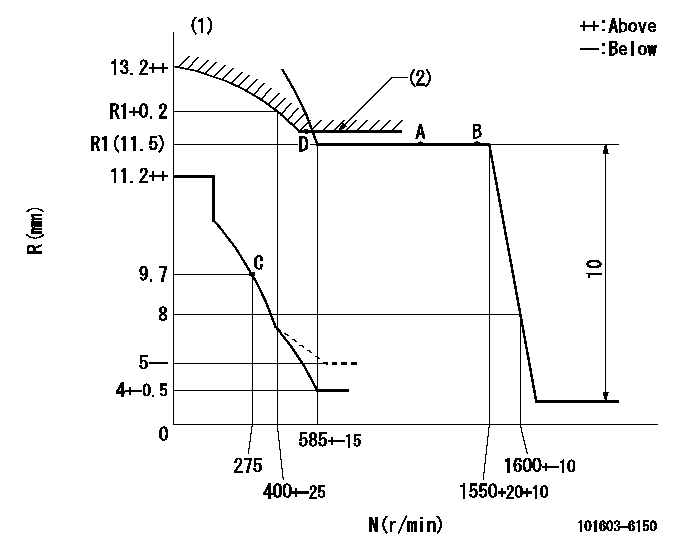

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Damper spring setting: DL

(2)Excess fuel setting for starting: SXL

----------

DL=6.5-0.2mm SXL=R1+0.2mm

----------

----------

DL=6.5-0.2mm SXL=R1+0.2mm

----------

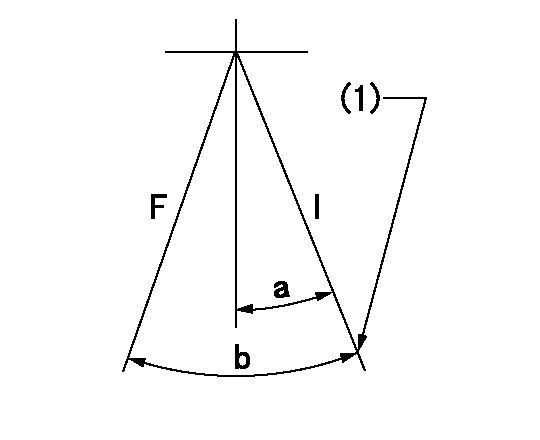

Speed control lever angle

F:Full speed

----------

----------

a=13deg+-5deg

----------

----------

a=13deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=9.5deg+-5deg b=27.5deg+-3deg

----------

----------

a=9.5deg+-5deg b=27.5deg+-3deg

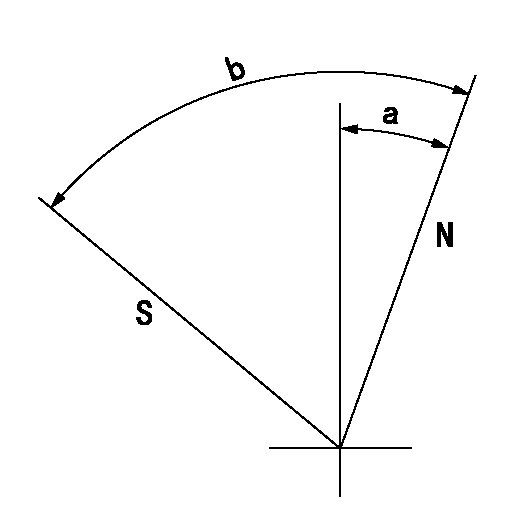

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=20deg+-5deg b=71deg+-5deg

----------

----------

a=20deg+-5deg b=71deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of timer's tooth at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=16deg

----------

a=(2deg)

----------

aa=16deg

----------

a=(2deg)

Information:

API Degrees - Temperature Correction Chart for Diesel Fuel

Record the corrected API gravity from this chart.Table of Horsepower Correction Factors

Table 2

Corrected API

Gravity at 60° F Precombustion

Chamber Engines Direct Injection Engines (Use the correct full load RPM)

1800 2000 2200 2400 2600 2800 3000 3200

32.0

32.5

33.0

33.5

34.0 .984

.987

.990

.992

.995 .986

.988

.990

.992

.995 .986

.988

.990

.992

.995 .986

.988

.990

.992

.995 .986

.988

.990

.992

.995 .986

.988

.990

.992

.995 .986

.988

.990

.992

.995 .986

.988

.990

.992

.995 .986

.988

.990

.992

.995

34.5

35.0

35.5

36.0

36.5 .997

1.000

1.003

1.005

1.008 .998

1.000

1.003

1.007

1.013 .998

1.000

1.003

1.007

1.010 .998

1.000

1.004

1.007

1.011 .998

1.000

1.004

1.007

1.011 .998

1.000

1.004

1.007

1.011 .998

1.000

1.004

1.008

1.012 .998

1.000

1.004

1.008

1.012 .998

1.000

1.004

1.008

1.012

37.0

37.5

38.0

38.5

39.0 1.011

1.014

1.017

1.020

1.023 1.014

1.018

1.022

1.025

1.029 1.014

1.018

1.022

1.026

1.030 1.014

1.018

1.022

1.026

1.030 1.015

1.019

1.022

1.026

1.030 1.015

1.019

1.023

1.027

1.031 1.016

1.020

1.024

1.028

1.032 1.016

1.020

1.024

1.028

1.033 1.016

1.021

1.025

1.029

1.034

39.5

40.0

40.5

41.0

41.5 1.027

1.030

1.034

1.038

1.043 1.034

1.038

1.043

1.048

1.053 1.034

1.038

1.043

1.048

1.054 1.034

1.039

1.044

1.049

1.055 1.035

1.040

1.045

1.050

1.056 1.036

1.040

1.045

1.051

1.056 1.036

1.041

1.046

1.051

1.057 1.037

1.042

1.047

1.053

1.059 1.039

1.045

1.047

1.057

1.064

42.0

42.5

43.0

43.5

44.0 1.047

1.053

1.060

1.067

1.076 1.059

1.066

1.073

1.082

1.095 1.060

1.067

1.074

1.084

1.096 1.061

1.068

1.076

1.085

1.098 1.062

1.069

1.077

1.086

1.099 1.063

1.070

1.078

1.087

1.100 1.064

1.071

1.079

1.088

1.102 1.066

1.072

1.081

1.091

1.105 1.072

1.080

1.089

1.099

1.115 Use the above chart to find the horsepower correction factor.Calculating the Corrected Horsepower

Determine the rated full load horsepower from the Rack Setting Information Book.

Divide the rated horsepower by the horsepower correction factor for fuel density; the result is the corrected horsepower.Example:1674 - Truck Engine Serial No. 94B2551Rated Horsepower: 270 HorsepowerCalculations:

Table 3

1. Measured API gravity: 40.4' API at 50' (round to 40' API)

2. Corrected API gravity (see chart): 41' API at 60'F

3. Hpr correction factor (see chart): 1.038

4. Corrected Hp = Rated Hpr = 270 = 260 Hp

Correction Factor 1.038 (or 3.75% hp loss) Correcting for Fuel Density When Testing Engines on a Dynamometer

When engines are tested on a dynamometer which measures actual flywheel or drive train output, the observed horsepower is dependent on the fuel used. If the fuel being used is not 35° API at 60°F, then any dynamometer readings must be corrected to determine the output if 35° API fuel had been used. The same horsepower correction factor is used, but the formula is different:Corrected Horsepower = Observed Horsepower x Horsepower Correction FactorExample:1674 Truck Engine, Serial No. 9482551Rated (full load Horsepower: 270 Horsepower)Observed (dynamometer) Horsepower: 260 HorsepowerCalculations:

Measured API gravity: 39.6° API at 50°F (round to 40° API)

Corrected API Gravity (see chart): 41° API at 60°F

Horsepower Correction Factor (see chart): 1.038

Corrected Horsepower = Observed Horsepower x Horsepower Correction Factor 260 horsepower x 1.038 = 270 horsepower(Although the dynamometer indicated low horsepower, if the proper fuel had been used, the engine would be operating at rated output. The factory tolerance on rated engine output is 3%.)REFERENCE: For more information on dynamometer testing diesel engines, see Special Instruction Form GEG01024 .Diesel Fuel API Gravity to IbsJU.S. gallon or kg/liter Conversion Chart

The following chart may be used to convert the fuel API gravity to Ibs./U.S. gallon or kg/liter. These weights are for reference and are to be used when evaluating engine performance. Measurement of fuel flow rates can be converted

Record the corrected API gravity from this chart.Table of Horsepower Correction Factors

Table 2

Corrected API

Gravity at 60° F Precombustion

Chamber Engines Direct Injection Engines (Use the correct full load RPM)

1800 2000 2200 2400 2600 2800 3000 3200

32.0

32.5

33.0

33.5

34.0 .984

.987

.990

.992

.995 .986

.988

.990

.992

.995 .986

.988

.990

.992

.995 .986

.988

.990

.992

.995 .986

.988

.990

.992

.995 .986

.988

.990

.992

.995 .986

.988

.990

.992

.995 .986

.988

.990

.992

.995 .986

.988

.990

.992

.995

34.5

35.0

35.5

36.0

36.5 .997

1.000

1.003

1.005

1.008 .998

1.000

1.003

1.007

1.013 .998

1.000

1.003

1.007

1.010 .998

1.000

1.004

1.007

1.011 .998

1.000

1.004

1.007

1.011 .998

1.000

1.004

1.007

1.011 .998

1.000

1.004

1.008

1.012 .998

1.000

1.004

1.008

1.012 .998

1.000

1.004

1.008

1.012

37.0

37.5

38.0

38.5

39.0 1.011

1.014

1.017

1.020

1.023 1.014

1.018

1.022

1.025

1.029 1.014

1.018

1.022

1.026

1.030 1.014

1.018

1.022

1.026

1.030 1.015

1.019

1.022

1.026

1.030 1.015

1.019

1.023

1.027

1.031 1.016

1.020

1.024

1.028

1.032 1.016

1.020

1.024

1.028

1.033 1.016

1.021

1.025

1.029

1.034

39.5

40.0

40.5

41.0

41.5 1.027

1.030

1.034

1.038

1.043 1.034

1.038

1.043

1.048

1.053 1.034

1.038

1.043

1.048

1.054 1.034

1.039

1.044

1.049

1.055 1.035

1.040

1.045

1.050

1.056 1.036

1.040

1.045

1.051

1.056 1.036

1.041

1.046

1.051

1.057 1.037

1.042

1.047

1.053

1.059 1.039

1.045

1.047

1.057

1.064

42.0

42.5

43.0

43.5

44.0 1.047

1.053

1.060

1.067

1.076 1.059

1.066

1.073

1.082

1.095 1.060

1.067

1.074

1.084

1.096 1.061

1.068

1.076

1.085

1.098 1.062

1.069

1.077

1.086

1.099 1.063

1.070

1.078

1.087

1.100 1.064

1.071

1.079

1.088

1.102 1.066

1.072

1.081

1.091

1.105 1.072

1.080

1.089

1.099

1.115 Use the above chart to find the horsepower correction factor.Calculating the Corrected Horsepower

Determine the rated full load horsepower from the Rack Setting Information Book.

Divide the rated horsepower by the horsepower correction factor for fuel density; the result is the corrected horsepower.Example:1674 - Truck Engine Serial No. 94B2551Rated Horsepower: 270 HorsepowerCalculations:

Table 3

1. Measured API gravity: 40.4' API at 50' (round to 40' API)

2. Corrected API gravity (see chart): 41' API at 60'F

3. Hpr correction factor (see chart): 1.038

4. Corrected Hp = Rated Hpr = 270 = 260 Hp

Correction Factor 1.038 (or 3.75% hp loss) Correcting for Fuel Density When Testing Engines on a Dynamometer

When engines are tested on a dynamometer which measures actual flywheel or drive train output, the observed horsepower is dependent on the fuel used. If the fuel being used is not 35° API at 60°F, then any dynamometer readings must be corrected to determine the output if 35° API fuel had been used. The same horsepower correction factor is used, but the formula is different:Corrected Horsepower = Observed Horsepower x Horsepower Correction FactorExample:1674 Truck Engine, Serial No. 9482551Rated (full load Horsepower: 270 Horsepower)Observed (dynamometer) Horsepower: 260 HorsepowerCalculations:

Measured API gravity: 39.6° API at 50°F (round to 40° API)

Corrected API Gravity (see chart): 41° API at 60°F

Horsepower Correction Factor (see chart): 1.038

Corrected Horsepower = Observed Horsepower x Horsepower Correction Factor 260 horsepower x 1.038 = 270 horsepower(Although the dynamometer indicated low horsepower, if the proper fuel had been used, the engine would be operating at rated output. The factory tolerance on rated engine output is 3%.)REFERENCE: For more information on dynamometer testing diesel engines, see Special Instruction Form GEG01024 .Diesel Fuel API Gravity to IbsJU.S. gallon or kg/liter Conversion Chart

The following chart may be used to convert the fuel API gravity to Ibs./U.S. gallon or kg/liter. These weights are for reference and are to be used when evaluating engine performance. Measurement of fuel flow rates can be converted

Have questions with 101603-6150?

Group cross 101603-6150 ZEXEL

Mitsubishi

101603-6150

9 400 615 113

ME032909

INJECTION-PUMP ASSEMBLY

6D15

6D15