Information injection-pump assembly

ZEXEL

101603-6060

1016036060

Rating:

Cross reference number

ZEXEL

101603-6060

1016036060

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5520

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

11

Pump speed

r/min

850

850

850

Each cylinder's injection qty

mm3/st.

60

58.1

61.9

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

10+-0.5

Pump speed

r/min

275

275

275

Each cylinder's injection qty

mm3/st.

10

8.9

11.1

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11)

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

60

59

61

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.6

Pump speed

r/min

1450

1450

1450

Average injection quantity

mm3/st.

80.5

78.5

82.5

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1-0.4

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

42.5

40.5

44.5

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

80

75

85

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

1250--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1200

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1350

Advance angle

deg.

2.4

1.9

2.9

Timer adjustment_04

Pump speed

r/min

1500

Advance angle

deg.

5

4.5

5.5

Remarks

Finish

Finish

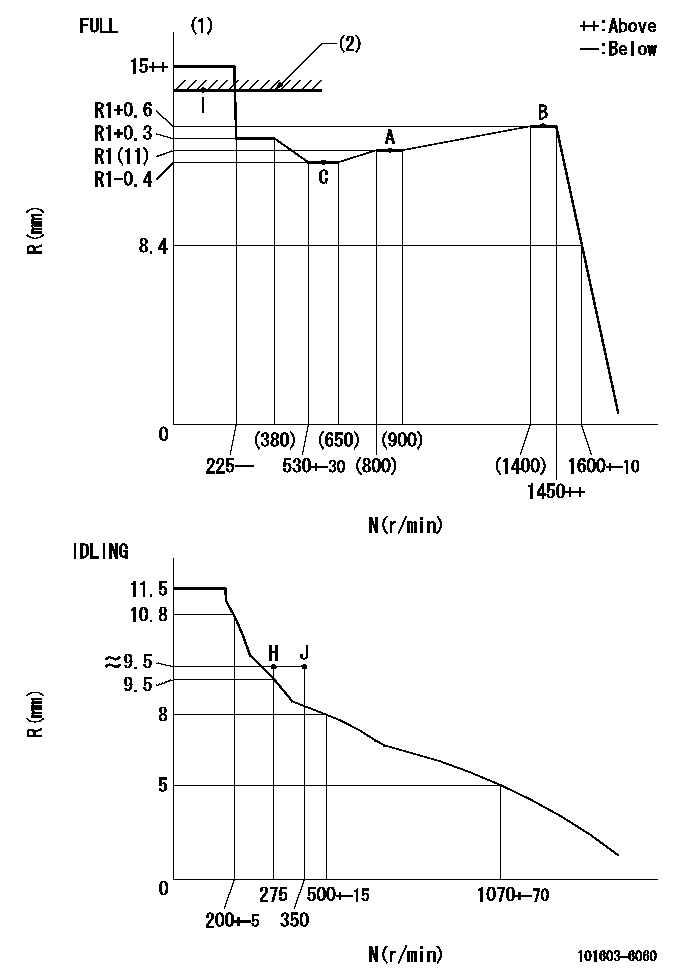

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)RACK LIMIT

----------

T1=A23

----------

----------

T1=A23

----------

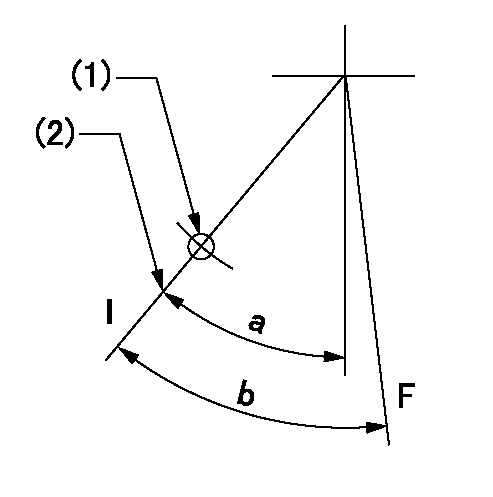

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=35mm

----------

a=33deg+-5deg b=35deg+-5deg

----------

aa=35mm

----------

a=33deg+-5deg b=35deg+-5deg

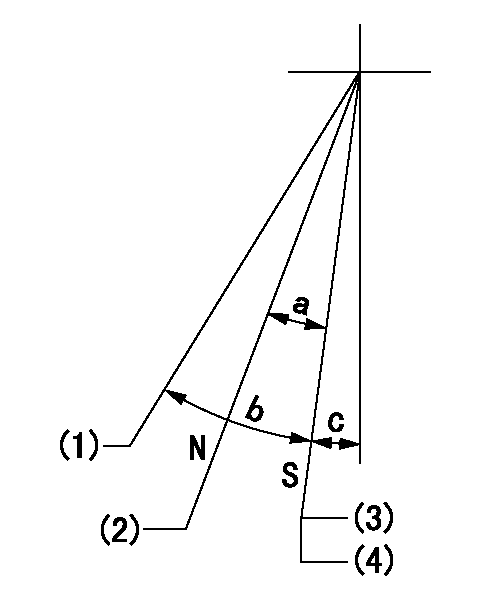

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Free (at shipping)

(2)Rack position = approximately aa.

(3)Set the stopper bolt at speed = rated point and rack position = bb. Confirm non-injection.

(4)After setting the stopper bolt, confirm non-injection at speed = cc.

----------

aa=17.4mm bb=(7)mm cc=275r/min

----------

a=17deg+-5deg b=(27deg) c=2deg+-5deg

----------

aa=17.4mm bb=(7)mm cc=275r/min

----------

a=17deg+-5deg b=(27deg) c=2deg+-5deg

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=400+-5r/min Ra=9.2mm

----------

----------

N1=400+-5r/min Ra=9.2mm

----------

Timing setting

(1)Pump vertical direction

(2)Position of timer's tooth at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=12deg

----------

a=(1deg)

----------

aa=12deg

----------

a=(1deg)

Information:

Introduction

Do not perform any procedure in this Special Instruction until you have read the information and you understand the information.There have been isolated occurrences of excessive fuel leakage past the electronic unit injectors on some engines.Accelerated wear on the delivery valve results in an increased leak rate. The high pressure pump cannot generate enough fuel flow or volume to compensate for the leakoff rates above the critical value 38 mL (1.3 oz) per 30 seconds of cranking for six cylinder engines at a speed of 150 rpm. The high pressure pump cannot generate enough fuel flow or volume to compensate for the leakoff rates above the critical value 25 mL (0.85 oz) per 30 seconds of cranking for four cylinder engines at a speed of 150 rpm.If the engine turns over but the engine does not start, refer to Troubleshooting, "Engine Cranks but Will Not Start".Test Procedure

Before begining any work on the fuel system, refer to Operation and Maintenance Manual, "General Hazard Information and High Pressure Fuel Lines" for safety information.Refer to Systems Operation, Testing and Adjusting, "Cleanliness of Fuel System Components" for detailed information on the standards of cleanliness that must be observed during ALL work on the fuel system.

Table 1

Required Tools

Tool Part Number Part Description Qty

A 334-3221 Fuel Leakoff Kit 1

Ensure that the engine is shut down.

Illustration 1 g02103090

Injector harness

Disconnect the injector harness (1) from the front of the engine.

Illustration 2 g02103093

Typical exampleNote: Direct any leaking fuel into a suitable container.

Remove the bolt (2) from the "fuel relief block" and save the bolt for reinstallation.

Illustration 3 g02103095

Fuel leakoff kit (A) Tooling (3) Clear plastic hose

Install tooling (A) to the "fuel relief block".

Slide the tooling through the banjo bolt in order to replace the bolt that was removed in the previous step.

Thread the tooling into the "fuel relief block" and slightly tighten the tooling.

Connect a plastic hose (3) onto the tooling. Place the opposite end of the plastic hose into a suitable container that is clean.

Crank the engine with the starting motor for 30 seconds.

Record the amount of fuel that has been collected. Conduct the test three times. Calculate the average of the three values.

For six cylinder engines, if more than 38 mL (1.3 oz) of fuel has been collected during the 30 second crank test, then there is high leakoff of the electronic unit injectors. For four cylinder engines, if more than 25 mL (0.85 oz) of fuel has been collected during the 30 second crank test, then there is high leakoff of the electronic unit injectors. If this is the case, replace the electronic unit injectors and the fuel injection lines. Return the original electronic unit injectors and the fuel injection lines to the parts return center.

For six cylinder

Do not perform any procedure in this Special Instruction until you have read the information and you understand the information.There have been isolated occurrences of excessive fuel leakage past the electronic unit injectors on some engines.Accelerated wear on the delivery valve results in an increased leak rate. The high pressure pump cannot generate enough fuel flow or volume to compensate for the leakoff rates above the critical value 38 mL (1.3 oz) per 30 seconds of cranking for six cylinder engines at a speed of 150 rpm. The high pressure pump cannot generate enough fuel flow or volume to compensate for the leakoff rates above the critical value 25 mL (0.85 oz) per 30 seconds of cranking for four cylinder engines at a speed of 150 rpm.If the engine turns over but the engine does not start, refer to Troubleshooting, "Engine Cranks but Will Not Start".Test Procedure

Before begining any work on the fuel system, refer to Operation and Maintenance Manual, "General Hazard Information and High Pressure Fuel Lines" for safety information.Refer to Systems Operation, Testing and Adjusting, "Cleanliness of Fuel System Components" for detailed information on the standards of cleanliness that must be observed during ALL work on the fuel system.

Table 1

Required Tools

Tool Part Number Part Description Qty

A 334-3221 Fuel Leakoff Kit 1

Ensure that the engine is shut down.

Illustration 1 g02103090

Injector harness

Disconnect the injector harness (1) from the front of the engine.

Illustration 2 g02103093

Typical exampleNote: Direct any leaking fuel into a suitable container.

Remove the bolt (2) from the "fuel relief block" and save the bolt for reinstallation.

Illustration 3 g02103095

Fuel leakoff kit (A) Tooling (3) Clear plastic hose

Install tooling (A) to the "fuel relief block".

Slide the tooling through the banjo bolt in order to replace the bolt that was removed in the previous step.

Thread the tooling into the "fuel relief block" and slightly tighten the tooling.

Connect a plastic hose (3) onto the tooling. Place the opposite end of the plastic hose into a suitable container that is clean.

Crank the engine with the starting motor for 30 seconds.

Record the amount of fuel that has been collected. Conduct the test three times. Calculate the average of the three values.

For six cylinder engines, if more than 38 mL (1.3 oz) of fuel has been collected during the 30 second crank test, then there is high leakoff of the electronic unit injectors. For four cylinder engines, if more than 25 mL (0.85 oz) of fuel has been collected during the 30 second crank test, then there is high leakoff of the electronic unit injectors. If this is the case, replace the electronic unit injectors and the fuel injection lines. Return the original electronic unit injectors and the fuel injection lines to the parts return center.

For six cylinder