Information injection-pump assembly

ZEXEL

101603-4812

1016034812

ISUZU

1156022153

1156022153

Rating:

Cross reference number

ZEXEL

101603-4812

1016034812

ISUZU

1156022153

1156022153

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

13.6

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

87

85.4

88.6

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

275

275

275

Average injection quantity

mm3/st.

8

6.7

9.3

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(13.6)

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

87

86

88

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.45

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

102.4

99.2

105.6

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

I

Rack position

-

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

95

95

103

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

1325--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1275

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1400

Advance angle

deg.

0.5

0

1

Remarks

Finish

Finish

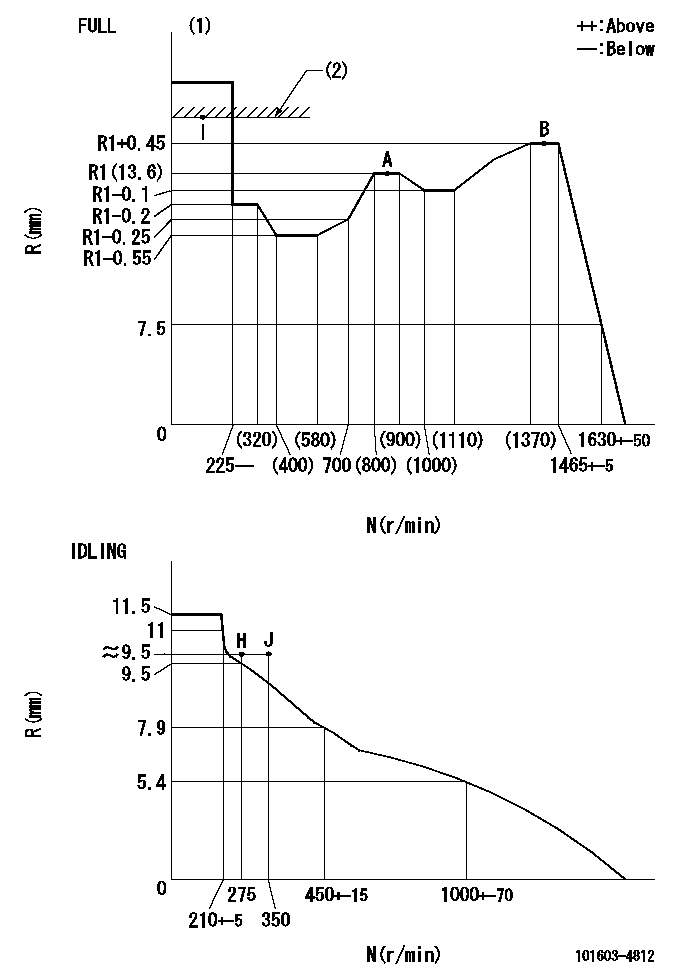

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)RACK LIMIT

----------

T1=C96

----------

----------

T1=C96

----------

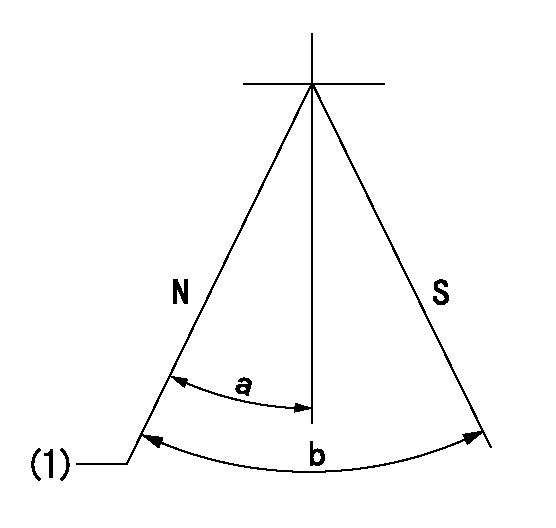

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt setting

----------

aa=35mm

----------

a=43deg+-5deg b=40deg+-3deg

----------

aa=35mm

----------

a=43deg+-5deg b=40deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Stopper bolt setting

----------

----------

a=25deg+-5deg b=40deg+-5deg

----------

----------

a=25deg+-5deg b=40deg+-5deg

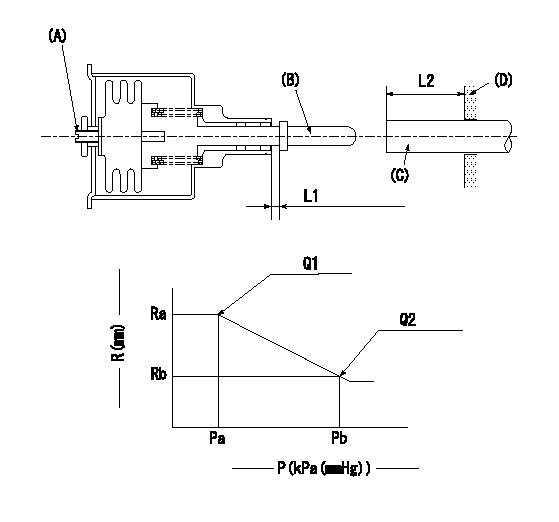

0000001501 ACS

(A) Set screw

(B) Push rod 1

(C) Push rod 2

(D) Cover

1. Aneroid compensator unit adjustment

(1)Select the push rod 2 to obtain L2.

(2)Screw in (A) to obtain L1.

2. Adjustment when mounting the governor.

(1)Set the speed of the pump to N1 r/min and fix the control lever at the full set position.

(2)Screw in the aneroid compensator to obtain the performance shown in the graph above.

(3)As there is hysterisis, measure when the absolute pressure drops.

(4)Hysterisis must not exceed rack position = h1.

----------

N1=1400r/min L1=(1.5)mm L2=11+-0.5mm h1=0.15mm

----------

Ra=R2(R1+0.45)mm Rb=R2-0.45mm Pa=92.6+-2.7kPa(695+-20mmHg) Pb=70.1+-0.7kPa(526+-5mmHg) Q1=(102.4)+-1.6cm3/1000st Q2=(94.3)+-1.6cm3/1000st

----------

N1=1400r/min L1=(1.5)mm L2=11+-0.5mm h1=0.15mm

----------

Ra=R2(R1+0.45)mm Rb=R2-0.45mm Pa=92.6+-2.7kPa(695+-20mmHg) Pb=70.1+-0.7kPa(526+-5mmHg) Q1=(102.4)+-1.6cm3/1000st Q2=(94.3)+-1.6cm3/1000st

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=14deg

----------

a=(60deg)

----------

aa=14deg

----------

a=(60deg)

Information:

Close the gauge protector valve ( 0 to 40,000 kPa (0 to 5,800 psi) gauge).

Visually inspect the pattern of the fuel nozzle for a uniform spray.Note: For this test, each full stroke of the pump should be performed in less than one second.

Rapidly increase the pressure on the fuel nozzle until fluid sprays from the tip of the fuel nozzle.

Test fluid should spray from the tip of the nozzle in a pattern that is uniform. Refer to Illustration 2.

Check the individual spray orifices for partial plugging.

Use a moderate pump stroke to open the valve of the fuel nozzle.

During the pump stroke, view the individual spray orifices for partial plugging.The test fluid should spray uniformly from all the orifices.If an orifice is plugged or the pattern is distorted, clean the fuel nozzle orifices and repeat this test. Refer to Special Instruction, SEHS8627, "Use of 8S-2245 Nozzle Cleaning Tool Group" for instructions on tool usage and cleaning procedures.Test the Fuel Nozzle for Seal Leakage

Note: Testing for seal leakage is not a requirement for the 104-9450 Fuel Nozzle, 104-9452 Fuel Nozzle, 104-9453 Fuel Nozzle, or the 104-9454 Fuel Nozzle. Do not perform this test on these fuel nozzles.

Illustration 3 g00453789

Typical example of a 7000 Series fuel nozzle

Remove the cloth from the top of the nozzle.

Prior to performing this test, install a new seal washer on purging screw (A) and reinstall the purging screw into the fuel nozzle.

Illustration 4 g00453809

Tighten purging screw (D) or purging screw (E) to a torque of 2.2 0.8 N m (20 7 lb in). Note: Use a 6V-4980 Torque Screwdriver Tool Group to torque the purging screw.

Apply a test pressure of 13,800 kPa (2,000 psi) to the fuel nozzle.Note: Due to the large amount of test fluid that is delivered to the fuel nozzle, hydraulic lock may prevent the nozzle from opening during this test. If a hydraulic lock occurs, slowly loosen the adapter fitting to relieve the pressure on the fuel nozzle valve assembly.If there is leakage at the purging screw, install a new 8C-3234 Screw and a 114-3364 Washer as replacement parts. Retest the fuel nozzle for leaks.Do not use the nozzle if there is leakage that cannot be repaired at purging screw (A), upper seal joint (B), or lower seal joint (C).Returning Fuel Nozzles to Service

Illustration 5 g00453817Prior to returning fuel nozzles to service, install a new seal washer (3) and install a new carbon dam (4) on the fuel nozzle (1).Use 6V-4979 Carbon Seal Installation Tool (2) to install a new carbon dam (4).Table 5 contains part numbers for the replacement of the fuel nozzle seal washers.

Table 5

Seal Washers

Fuel Nozzle Washer (Color) Washer Thickness

8N-7004 4W-3914 (Gray) 1.27 mm (0.050 inch)

4W-7012

4W-7013

4W-7014

4W-7015 4W-6060 (Blue) 3.18 mm (0.125 inch)

4W-7018

4W-7019

4W-7020

4W-7021

4W-7022

7W-7045

100-7552

100-7562

100-7563

104-3377

167-7489

170-5181

170-5183 7W-4482 (Green) 3.18 mm (0.125 inch)

133-3896 7W-4483 (Red) 2.54 mm (0.100 inch)

4W-7011

4W-7016

7W-7024 7W-4485 (Copper) 1.27 mm (0.050 inch)

8N-7003

7W-7038

8N-7005

100-7559

100-7561

100-7564

104-9450

104-9452

104-9453

104-9454

131-3190

154-3198

170-5187 7W-4486 (Violet) 1.84 mm (0.072 inch)

4W-7017

7W-7026

7W-7030

7W-7031

7W-7032

7W-7033

7W-7035

7W-7037

7W-7040

7W-7041

7W-7042

7W-7043

7W-7044

8N-7007

100-7550

100-7551

100-7556

100-7557

100-7558

100-7560

100-7565

100-7567

100-7600

121-4353

127-9792

127-9793

129-1351

130-1804

130-1806

130-5187

130-5190

131-0811

131-0812

131-1242

131-1243

131-7937

134-0944

171-4093 7W-4487 (Black) 1.27 mm (0.050 inch)

7W-7023