Information injection-pump assembly

ZEXEL

101603-4701

1016034701

ISUZU

1156021811

1156021811

Rating:

Cross reference number

ZEXEL

101603-4701

1016034701

ISUZU

1156021811

1156021811

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-4920

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.7

3.65

3.75

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

12.5

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

107.2

105.6

108.8

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

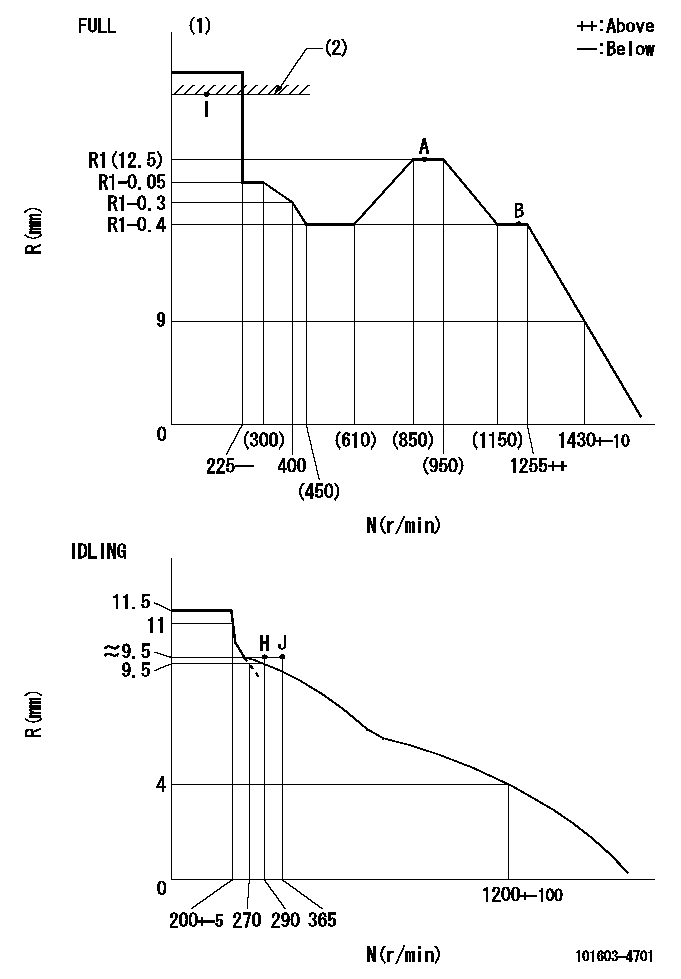

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

290

290

290

Average injection quantity

mm3/st.

9.9

7.9

11.9

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(12.5)

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

107.2

106.2

108.2

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1-0.4

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

100.6

97.4

103.8

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

98.5

98.5

108.5

Fixing the lever

*

Timer adjustment

Pump speed

r/min

950--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

900

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1250

Advance angle

deg.

2

1.5

2.5

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)RACK LIMIT

----------

T1=C68

----------

----------

T1=C68

----------

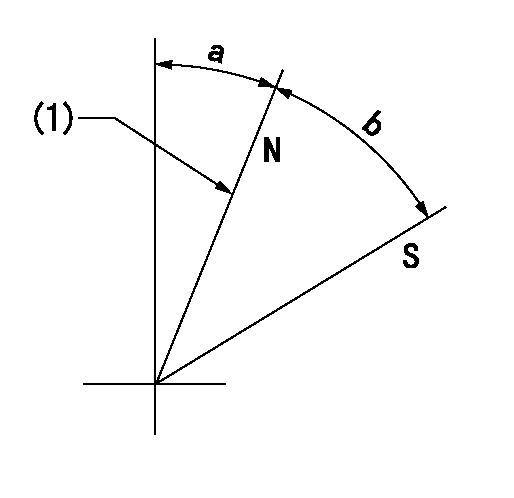

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H'

----------

----------

a=18deg+-5deg b=30deg+-3deg

----------

----------

a=18deg+-5deg b=30deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Stopper bolt setting

----------

----------

a=25deg+-5deg b=40deg+-5deg

----------

----------

a=25deg+-5deg b=40deg+-5deg

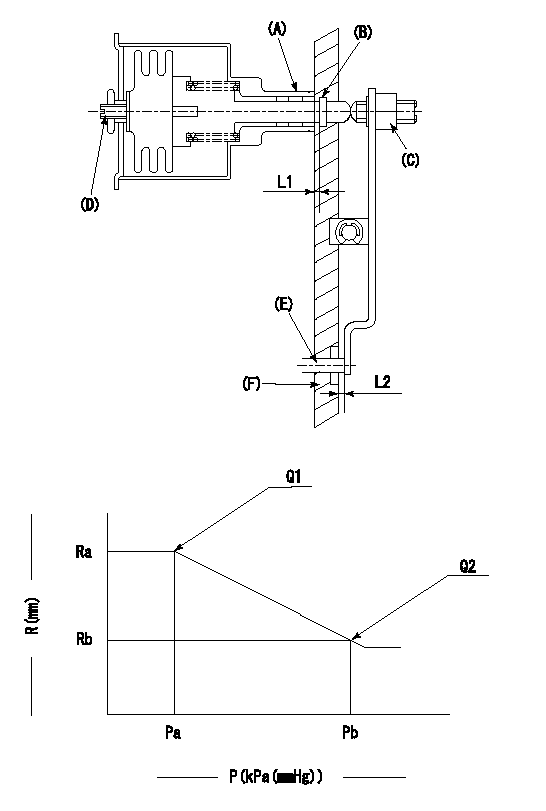

0000001501 ACS

(A) Housing

(B) Snap ring

(C) adjusting screw

(D) Set screw

(E): Push rod

(F) Spacer

1. Adjustment of the aneroid compensator

(1)Adjust with the (D) set screw so that the clearance between the (A) housing and (B) snap ring is L1.

(2)Select the push rod (E) so that the distance from the end surface of the (F) spacer becomes L2.

(3)(C) Turn the screw to adjust the beginning of aneroid compensator operation.

2. Adjustment when mounting the governor.

(1)Set the speed of the pump to N1 r/min and fix the control lever at the full set position.

(2)Adjust using screw C to obtain the performance shown in the graph above.

(3)After final adjustment, confirm that the gap between housing (A) and snapring (B) is L3.

----------

N1=900r/min L1=1.4~1.7mm L2=0.5+-0.5mm L3=(0.1~0.5)mm

----------

Ra=R1(12.5)mm Rb=(R1-0.2)mm Pa=77.3+-2.7kPa(580+-20mmHg) Pb=65.3+-0.7kPa(490+-5mmHg) Q1=107.2+-1cm3/1000st Q2=101.9+-1.6cm3/1000st

----------

N1=900r/min L1=1.4~1.7mm L2=0.5+-0.5mm L3=(0.1~0.5)mm

----------

Ra=R1(12.5)mm Rb=(R1-0.2)mm Pa=77.3+-2.7kPa(580+-20mmHg) Pb=65.3+-0.7kPa(490+-5mmHg) Q1=107.2+-1cm3/1000st Q2=101.9+-1.6cm3/1000st

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=11deg

----------

a=(40deg)

----------

aa=11deg

----------

a=(40deg)

Information:

TECHNICAL INFORMATION BULLETIN March 05, 2003

Articulated Truck

Cold Planer

Landfill Compactor

Excavator

Motor Grader

Off-Highway Truck/Tractor

Quarry Truck

Track-Type Tractor

Underground Articulated Truck

Wheel Loader

Wheel Tractor

Wheel Tractor-Scraper D30C (05A)

PM-565 (3TK)

PM-565B (8GS)

836 (7FR)

5110B (AAA)

24H (7KK)

69D (9SS, 9XS)

73D (1GW)

769D (BBB, 5SS, 5TR)

773D (7ER, 7CS)

771D (BCA, 6JR, 6YS)

775D (6KR, 8AS)

D10R (3KR)

D9R (ABK, ACL, 7TL, 8BL)

AD40 II (1YZ)

AD45 (BKZ)

AE40 II (BLW, 1ZZ)

988F II (2ZR)

990 II (4FR)

834B (7BR)

844 (2KZ)

631E II (1AB1446-Up, 1NB)

631E (1AB1-1445)

631G (AWK)

633E II (2PS)

637E II (1FB532-Up)

637E (1FB1-531)

637G (AXT)

651E (4YR)

657E (5YR, 6PR, 6TR, 7KR)

Component Code: 1901SUBJECT: Flashing New Software When Electronic Control Module (ECM) or Injectors Are Replaced

PROBLEM:

There have been dealer reports of engine ECMs locking up when new software is being installed. Dealer staff may see a message on the service tool such as: "The ECM is not responding to the service tool. Error code 864256". The flashing will typically hang up after 88% complete. When you reconnect, ET will not be able to communicate. Messages you typically get: "The communication adapter was unable to connect to the ATA data link. Error # 441. The requested protocol is not compatible with an existing datalink." You may also see: "The software file and the ECM are not compatible. Process aborted ? Error Code: 147456."

The two new software part numbers are:

222-XXXX (needed when a 172-0802 ECM is replaced by a 156-7156 ECM)

214-YYYY (needed when new-style injectors are installed)

SOLUTION:

If you are considering performing Product Support Program PS50424 on one of the above-listed machines, you may want to delay the program until new software is released. New software will be released in the near future to resolve this issue. Once the flashfiles are in SIS Web, a follow-up TIB will announce the new software?s availability.

On machine engines that have an older ECM that fails (145-7808 or 172-0802), the current 156-7172 production ECM will be needed for parts service. This will require using one of the 222-XXXX flashfiles. To minimize the possibility of locking-up the ECM, the dealer service staff can do one of the following:

Flash the ECM before traveling to the job site. This will require a By-Pass harness.

Flash the ECM on the engine. A By-Pass harness is recommended. If a By-Pass harness is used, disconnect the machine wiring harness before flashing the engine ECM. Dealers report that this method reduces the number of lock-ups.

If the dealer does not have a By-Pass harness, one will have to be purchased or assembled. If a new 129-2018 Wiring Harness Assembly (By-Pass) is purchased, modifications are necessary. Instructions on how to modify a By-Pass harness (Method 1: Modify a By-Pass Harness) and assemble a By-Pass harness (Method 2: Assemble a By-Pass Harness) appear later in this TIB.

Note: When flashing engine ECMs, always download the file from SIS Web to the computer?s hard drive. The service person should then upload (flash) to the ECM from the computer?s hard drive. For a listing of all models affected and the current software, refer to REHS1385-02, "Introduction of New 3408E and 3412E Hydraulic Electronic Unit Injectors".

Method 1: Modify a By-Pass Harness

When flashing an on-engine ECM with the current files, Caterpillar recommends the use