Information injection-pump assembly

BOSCH

9 400 615 078

9400615078

ZEXEL

101603-4321

1016034321

ISUZU

1156019064

1156019064

Rating:

Service parts 101603-4321 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

1-15300-104-2

12.

Open Pre:MPa(Kqf/cm2)

18.1{185}

15.

NOZZLE SET

Include in #1:

101603-4321

as INJECTION-PUMP ASSEMBLY

Include in #2:

104749-6650

as _

Cross reference number

BOSCH

9 400 615 078

9400615078

ZEXEL

101603-4321

1016034321

ISUZU

1156019064

1156019064

Zexel num

Bosch num

Firm num

Name

101603-4321

9 400 615 078

1156019064 ISUZU

INJECTION-PUMP ASSEMBLY

6BG1 K 14BE INJECTION PUMP ASSY PE6A PE

6BG1 K 14BE INJECTION PUMP ASSY PE6A PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

11.4

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

70.7

69.1

72.3

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

9.6+-0.5

Pump speed

r/min

260

260

260

Average injection quantity

mm3/st.

9.4

8.1

10.7

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.4)

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

70.7

69.7

71.7

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

(R1-0.4)

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

76

74.4

77.6

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

I

Rack position

-

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

86

86

96

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

550--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

500

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1500

Advance angle

deg.

4

3.5

4.5

Remarks

Finish

Finish

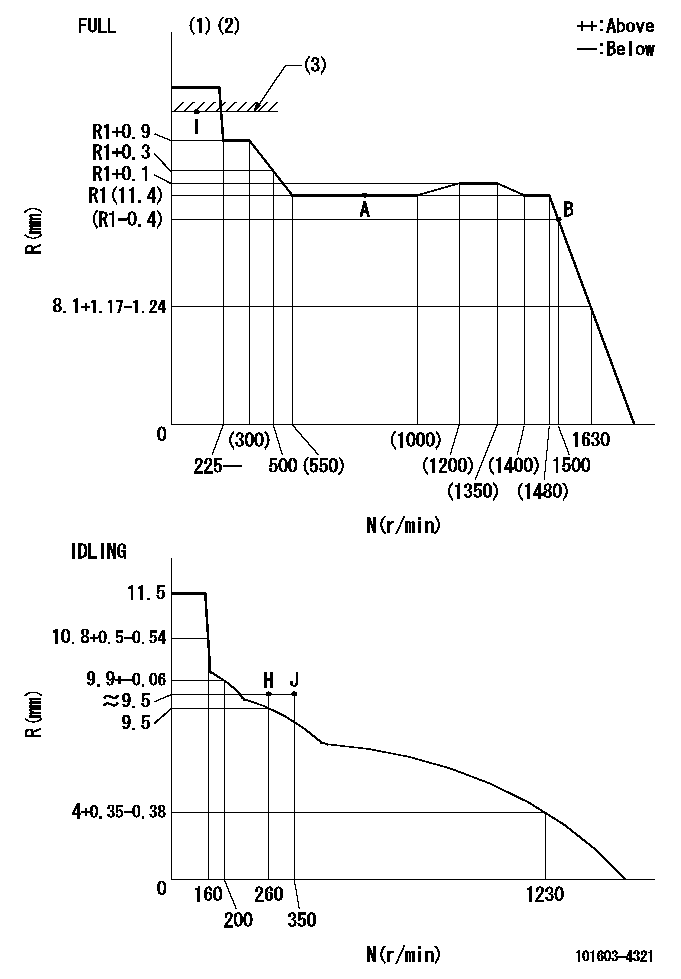

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

----------

T1=E60

----------

----------

T1=E60

----------

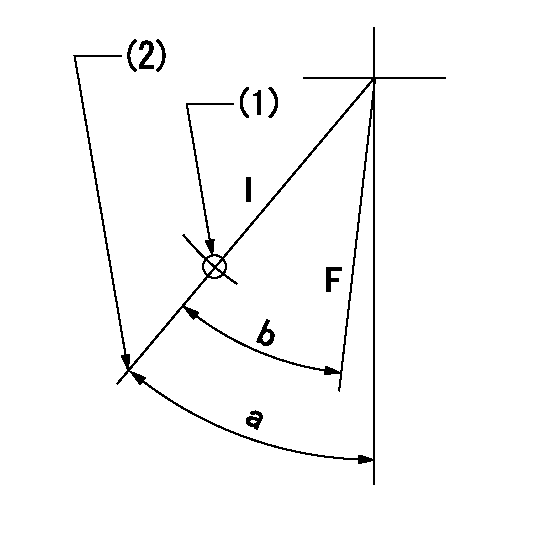

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=35mm

----------

a=42deg+-5deg b=35deg+-3deg

----------

aa=35mm

----------

a=42deg+-5deg b=35deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=25deg+-5deg b=40deg+-5deg

----------

----------

a=25deg+-5deg b=40deg+-5deg

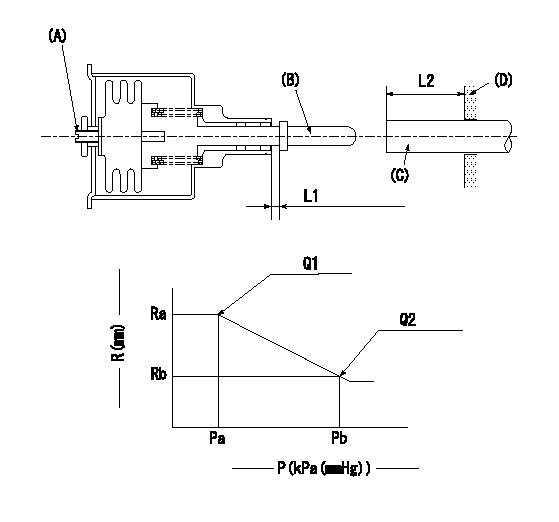

0000001501 ACS

(A) Set screw

(B) Push rod 1

(C) Push rod 2

(D) Cover

1. Aneroid compensator unit adjustment

(1)Select the push rod 2 to obtain L2.

(2)Screw in (A) to obtain L1.

2. Adjustment when mounting the governor.

(1)Set the speed of the pump to N1 r/min and fix the control lever at the full set position.

(2)Screw in the aneroid compensator to obtain the performance shown in the graph above.

(3)As there is hysterisis, measure when the absolute pressure drops.

(4)Hysterisis must not exceed rack position = h1.

----------

N1=900r/min L1=(1.5)mm L2=11+-0.5mm h1=0.15mm

----------

Ra=R1(11.4)mm Rb=R1-0.7mm Pa=89.8+-2.7kPa(674+-20mmHg) Pb=70.1+-0.7kPa(526+-5mmHg) Q1=70.7+-1cm3/1000st Q2=(59.1)cm3/1000st

----------

N1=900r/min L1=(1.5)mm L2=11+-0.5mm h1=0.15mm

----------

Ra=R1(11.4)mm Rb=R1-0.7mm Pa=89.8+-2.7kPa(674+-20mmHg) Pb=70.1+-0.7kPa(526+-5mmHg) Q1=70.7+-1cm3/1000st Q2=(59.1)cm3/1000st

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=14deg

----------

a=(60deg)

----------

aa=14deg

----------

a=(60deg)

Information:

(1) Remove the plug in the dash and install 3T306 Starting Aid Switch (1). Connect two purple wires (2), from the wiring harness, to switch (1).(2) On machines with a bulldozer, remove two nuts (3), washers and bolts. Remove two bolts (4) and washers. Remove bracket (5) from bracket (6). (3) Put 7G6359 Box Assembly (7) in position and install two 5F4899 Bolts (8) and 5M2894 Washers. Install two S1594 Bolts (9), 5P1075 Washers and 1D4717 Nuts to hold box assembly (7) to bracket (6). Install 4M7470 Grommet in hole (A).(4) Put the wires of 6N7674 Valve Assembly (10) through hole (A) and install valve assembly (10) on box assembly (7) with two S1617 Bolts (11), 5P4116 Washers and 1D4716 Nuts. Install 7N2059 Clamp Assembly (12) with two S1617 Bolts, 5P4116 Washers and 1D4716 Nuts. Install 63801 Washer (13) on 6D1746 Bolt (14). Put bolt (14) in position in cover (15) and install L1365 Washer (16) on bolt (14). Install 3B4610 Cotter Pin (17) in bolt (14). (5) Remove the plug from the manifold and install 6N9995 Atomizer Assembly (18) as shown. The orifices of the atomizer must be toward each end of the manifold. Install 5P7907 Connector (19) in valve assembly (10). Connect 9G941 Tube (20) to atomizer assembly (18). Use 5P6314 Sleeve (21) and 5P6313 Nut (22) to connect tube (20) to connector (19). Remove the plug from the bypass elbow of the water lines group and install 6N5899 Switch (23). Connect 9G6560 Wire Assembly (24) to switch (23) and to valve assembly (10). Connect 9G6561 Wire Assembly (25) to valve assembly (10) and to the purple wire, from the starting aid switch, at the rear of the engine. Use former clips (26) to hold wire assemblies (24) and (25) in position.(6) Remove cap (27) from valve assembly (10) and install a 7N296 Cylinder Assembly. (7) For machines without bulldozer lines, remove the two bolts from the cylinder head and put 7G6359 Box Assembly (7) in position. Install two 5F4899 Bolts (8) and 5M2894 Washers. Remove the bolt from the exhaust manifold and put 3T1685 Bracket (27) in position. Install L2070 Bolt (28), 5M2894 Washer and 1D4717 Nut. Install two S1594 Bolts (9), 5P1075 Washers and 1D4717 Nuts. Install the 4M7470 Grommet in hole (A), see Step 3. Follow Steps 1, 4, 5 and 6 for installation of the group.

Have questions with 101603-4321?

Group cross 101603-4321 ZEXEL

Isuzu

Isuzu

101603-4321

9 400 615 078

1156019064

INJECTION-PUMP ASSEMBLY

6BG1

6BG1