Information injection-pump assembly

BOSCH

9 400 615 062

9400615062

ZEXEL

101603-2740

1016032740

HINO

220206020A

220206020a

Rating:

Service parts 101603-2740 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

23600-1593A

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 615 062

9400615062

ZEXEL

101603-2740

1016032740

HINO

220206020A

220206020a

Zexel num

Bosch num

Firm num

Name

101603-2740

9 400 615 062

220206020A HINO

INJECTION-PUMP ASSEMBLY

W06D K 14BE INJECTION PUMP ASSY PE6A PE

W06D K 14BE INJECTION PUMP ASSY PE6A PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5720

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.1

3.05

3.15

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

8.2

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

33.7

31.7

35.7

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

7.4+-0.5

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

8

6.5

9.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

60

70

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

1100--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1050

Advance angle

deg.

0.3

Timer adjustment_03

Pump speed

r/min

1400

Advance angle

deg.

1.8

1.5

2.1

Timer adjustment_04

Pump speed

r/min

-

Advance angle

deg.

4.5

4.5

4.5

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

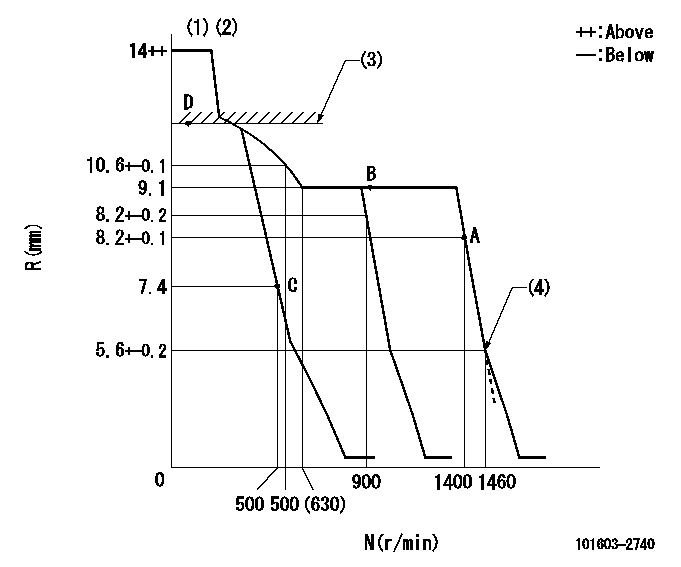

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Idle sub spring setting: L1.

----------

K=12 L1=5.6-0.5mm

----------

----------

K=12 L1=5.6-0.5mm

----------

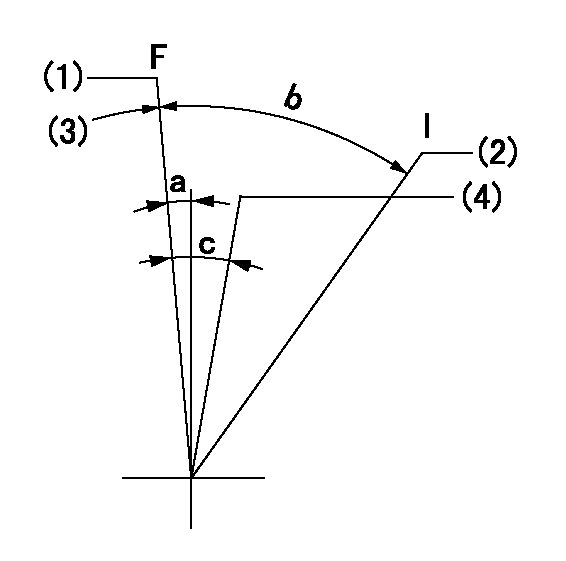

Speed control lever angle

F:Full speed

I:Idle

(1)Set the pump speed at aa

(2)Stopper bolt setting

(3)Stopper bolt setting

(4)When pump speed set at bb

----------

aa=1400r/min bb=900r/min

----------

a=10deg+-5deg b=22deg+-5deg c=12deg+-5deg

----------

aa=1400r/min bb=900r/min

----------

a=10deg+-5deg b=22deg+-5deg c=12deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

(2)Rack position aa or less, pump speed bb

----------

aa=6.9mm bb=0r/min

----------

a=27deg+-5deg b=53deg+-5deg

----------

aa=6.9mm bb=0r/min

----------

a=27deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

Typical Example1. Remove bolts (1) and cover (2). Remove bolts (3) and cover (4).

Typical Example2. Remove bolts (5) and adapter (6). Be sure that gear stays in place. Remove bolts (7) and cover (8). Keep gear in place.

Typical Example3. Remove gears (9) and crankshaft gear (10). Remove bolts (11) and idler gear (12) with retainer. Remove bolts (13) and idler gear (14) with retainer.

Typical Example4. Secure strap and a hoist to housing (15). Remove hose assembly (16) and small bolts (17) and large bolts (18). 5. Remove bolts (19) that connect housing to oil pan (20). Remove housing from cylinder block. The weight of housing is approximately 105 kg (230 lb). 6. Check O-ring seal (21) and bearing (22) on adapter and replace if necessary. 7. Check bearing (23) and O-ring seal (24) on cover and replace if necessary. 8. Remove retainer (25) from gear (9) and check bearings (26) and replace if necessary. The following steps are for the installation of the flywheel housing.9. Thoroughly clean the contact surfaces of the cylinder block and flywheel housing. Install a new gasket between the flywheel housing and the cylinder clock.10. Secure strap and a hoist to the flywheel housing, put flywheel housing in position on the cylinder block. 11. Install the bolts that hold the flywheel housing to the cylinder block. Tighten bolts 1 thru 22 in number sequence to a torque of 40 10 N m (30 7 lb ft). Tighten bolts 1 thru 9 in number sequence again to a torque of 135 20 N m (100 15 lb ft). Tighten bolts 10 thru 22 in number sequence again to a torque of 55 10 N m (40 7 lb ft).12. Install bolts that connect housing to oil pan.13. Cut flywheel housing gasket off even with the cylinder block surface. Remove excess sealant.End By:a. install crankshaft rear seal and wear sleeveb. install starting motor

Have questions with 101603-2740?

Group cross 101603-2740 ZEXEL

Hino

101603-2740

9 400 615 062

220206020A

INJECTION-PUMP ASSEMBLY

W06D

W06D