Information injection-pump assembly

BOSCH

9 400 611 993

9400611993

ZEXEL

101603-2632

1016032632

HINO

220205510B

220205510b

Rating:

Service parts 101603-2632 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

23600-2710A

12.

Open Pre:MPa(Kqf/cm2)

17.7{180}

15.

NOZZLE SET

Include in #1:

101603-2632

as INJECTION-PUMP ASSEMBLY

Include in #2:

104740-1430

as _

Cross reference number

BOSCH

9 400 611 993

9400611993

ZEXEL

101603-2632

1016032632

HINO

220205510B

220205510b

Zexel num

Bosch num

Firm num

Name

101603-2632

9 400 611 993

220205510B HINO

INJECTION-PUMP ASSEMBLY

H07C-TE K 14BF INJECTION PUMP ASSY PE6AD PE

H07C-TE K 14BF INJECTION PUMP ASSY PE6AD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-0920

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

4.8

4.77

4.83

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

A

Rack position

11.8

Pump speed

r/min

1300

1300

1300

Average injection quantity

mm3/st.

121.5

119.5

123.5

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

37.3

37.3

Boost pressure

mmHg

280

280

Injection quantity adjustment_02

Adjusting point

-

Rack position

6.2+-0.5

Pump speed

r/min

550

550

550

Average injection quantity

mm3/st.

10

9

11

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Boost compensator adjustment

Pump speed

r/min

800

800

800

Rack position

R1-0.7

Boost pressure

kPa

10.7

10.7

12

Boost pressure

mmHg

80

80

90

Boost compensator adjustment_02

Pump speed

r/min

800

800

800

Rack position

R1(11.8)

Boost pressure

kPa

24

24

24

Boost pressure

mmHg

180

180

180

Timer adjustment

Pump speed

r/min

1100--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1050

Advance angle

deg.

0.3

Timer adjustment_03

Pump speed

r/min

1300

Advance angle

deg.

1.5

1.2

1.8

Remarks

Finish

Finish

Test data Ex:

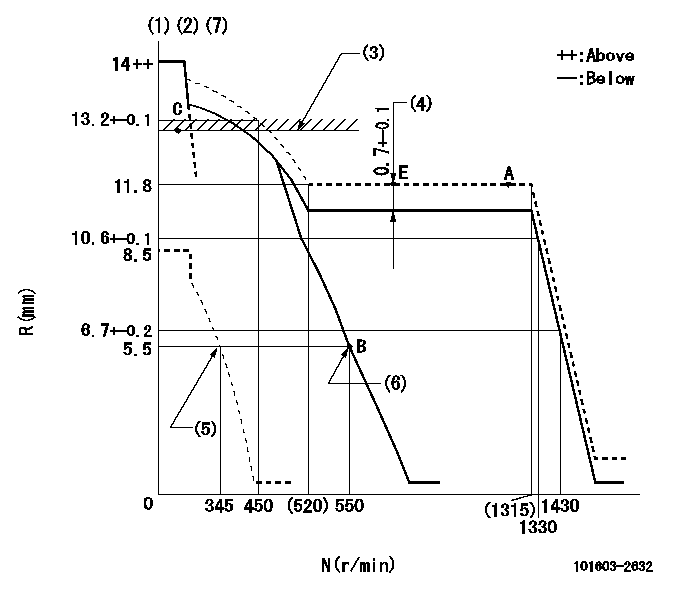

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)SMA RACK LIMIT; RAL (boost pressure exceeds P1 at N = N1)

(4)Boost compensator stroke

(5)Set idle sub-spring

(6)Main spring setting

(7)Perform governor adjustment at an ambient temperature of at least 15 deg C (rack limit spring is shape memory alloy).

----------

K=13 RAL=13.1+-0.1mm N1=350r/min P1=37.3kPa(280mmHg)

----------

----------

K=13 RAL=13.1+-0.1mm N1=350r/min P1=37.3kPa(280mmHg)

----------

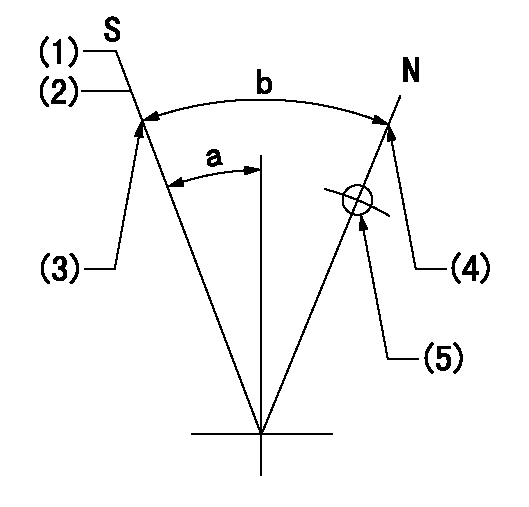

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=16deg+-5deg b=24deg+-5deg

----------

----------

a=16deg+-5deg b=24deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Pump speed aa and rack position bb (to be sealed at delivery)

(2)Normal stop

(3)Stopper bolt setting

(4)Stopper bolt setting

(5)Use the hole above R = cc

----------

aa=0r/min bb=1-0.5mm cc=25mm

----------

a=13deg+-5deg b=50deg+-5deg

----------

aa=0r/min bb=1-0.5mm cc=25mm

----------

a=13deg+-5deg b=50deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(50deg)

----------

----------

a=(50deg)

Information:

Start By:a. remove rocker shaft assembliesb. remove turbochargers1. Remove the valve cover bases from the cylinder head. 2. Remove sensor (7) from cylinder head (8). If necessary, remove the O-ring seal from sensor (7).3. Remove bolt and locknut (5).4. Disconnect connector (6).5. Remove bolt (4) and sensor (3). If necessary, remove the O-ring seal from sensor (3).6. Remove three bolts (2) and water lines group (1). 7. Remove bolt (9) from timing advance housing.8. Remove bolt (10) and support (11). 9. Remove the bolt and support (12). Remove the remaining ten bolts and the supports along the intake side of the cylinder head.10. Disconnect hose clamp (13) from the exhaust manifold. 11. Attach Tool (A) and fasten a hoist.12. Remove bolts (14) and remove the cylinder head. The weight of the cylinder head is approximately 172 kg (380 lb).13. Remove the head gasket and the water seals.

Do not put the cylinder head down on a flat surface. Direct injection nozzles extend out from the bottom surface of the cylinder head and will be damaged by the weight of the head.

Install Cylinder Head

1. Thoroughly clean the bottom surface of the cylinder head. Install a new head gasket and water seals. Do not use any adhesives. A new spacer plate gasket must be used when the cylinder head is installed. See the topic "Remove & Install Spacer Plate" in this module. 2. Attach Tool (D) and fasten a hoist.3. Install the cylinder head to the block. The weight of the cylinder head is approximately 172 kg (380 lb).

(1) Large bolts (3/4 inch). Put 6V-4876 Molycoat Paste Lubricant on bolt threads and between washer and underside of bolt heads. (2) Small bolts (3/8 inch). See Step 4h.4. Use the tightening sequence below to tighten the bolts that hold the cylinder head in position. a. Tighten bolts 1 through 14 in number sequence to 270 25 N m (200 20 lb ft).b. Tighten bolts 1 through 14 in number sequence to 470 20 N m (345 15 lb ft).c. Tighten bolts 1 through 14 in number sequence to 470 20 N m (345 15 lb ft).d. Install the rocker arm shafts for the engine valves and the remaining (3/4 in) bolts.e. Tighten bolts 15 through 26 in number sequence to 270 25 N m (200 20 lb ft).f. Tighten bolts 15 through 26 in number sequence to 450 20 N m (330 15 lb ft).g. Tighten bolts 15 through 26 in number sequence to 450 20 N m (330 15 lb ft).h. Tighten the thirteen small bolts (2) to a torque of 45 7 N m (33 5 lb ft). 5. Install support (12).6. Connect hose clamp (13) to exhaust manifold. 7. Install bolt (10) and support (11). Install the remaining ten bolts and the supports along the intake side of the cylinder head. Torque all twelve bolts (10) to 43 7 N m (32 5

Do not put the cylinder head down on a flat surface. Direct injection nozzles extend out from the bottom surface of the cylinder head and will be damaged by the weight of the head.

Install Cylinder Head

1. Thoroughly clean the bottom surface of the cylinder head. Install a new head gasket and water seals. Do not use any adhesives. A new spacer plate gasket must be used when the cylinder head is installed. See the topic "Remove & Install Spacer Plate" in this module. 2. Attach Tool (D) and fasten a hoist.3. Install the cylinder head to the block. The weight of the cylinder head is approximately 172 kg (380 lb).

(1) Large bolts (3/4 inch). Put 6V-4876 Molycoat Paste Lubricant on bolt threads and between washer and underside of bolt heads. (2) Small bolts (3/8 inch). See Step 4h.4. Use the tightening sequence below to tighten the bolts that hold the cylinder head in position. a. Tighten bolts 1 through 14 in number sequence to 270 25 N m (200 20 lb ft).b. Tighten bolts 1 through 14 in number sequence to 470 20 N m (345 15 lb ft).c. Tighten bolts 1 through 14 in number sequence to 470 20 N m (345 15 lb ft).d. Install the rocker arm shafts for the engine valves and the remaining (3/4 in) bolts.e. Tighten bolts 15 through 26 in number sequence to 270 25 N m (200 20 lb ft).f. Tighten bolts 15 through 26 in number sequence to 450 20 N m (330 15 lb ft).g. Tighten bolts 15 through 26 in number sequence to 450 20 N m (330 15 lb ft).h. Tighten the thirteen small bolts (2) to a torque of 45 7 N m (33 5 lb ft). 5. Install support (12).6. Connect hose clamp (13) to exhaust manifold. 7. Install bolt (10) and support (11). Install the remaining ten bolts and the supports along the intake side of the cylinder head. Torque all twelve bolts (10) to 43 7 N m (32 5

Have questions with 101603-2632?

Group cross 101603-2632 ZEXEL

Hino

Hino

101603-2632

9 400 611 993

220205510B

INJECTION-PUMP ASSEMBLY

H07C-TE

H07C-TE