Information injection-pump assembly

ZEXEL

101603-2240

1016032240

HINO

220204600A

220204600a

Rating:

Cross reference number

ZEXEL

101603-2240

1016032240

HINO

220204600A

220204600a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-0920

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

4.8

4.77

4.83

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

A

Rack position

10.4

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

94

92.5

95.5

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

24.7

24.7

Boost pressure

mmHg

185

185

Injection quantity adjustment_02

Adjusting point

-

Rack position

6+-0.5

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

10

9

11

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

130

130

140

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

R1-0.8

Boost pressure

kPa

4

2.7

5.3

Boost pressure

mmHg

30

20

40

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

R1(10.8)

Boost pressure

kPa

11.3

11.3

11.3

Boost pressure

mmHg

85

85

85

Timer adjustment

Pump speed

r/min

900--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

850

Advance angle

deg.

0.3

Timer adjustment_03

Pump speed

r/min

1050

Advance angle

deg.

1.5

1.2

1.8

Remarks

Finish

Finish

Test data Ex:

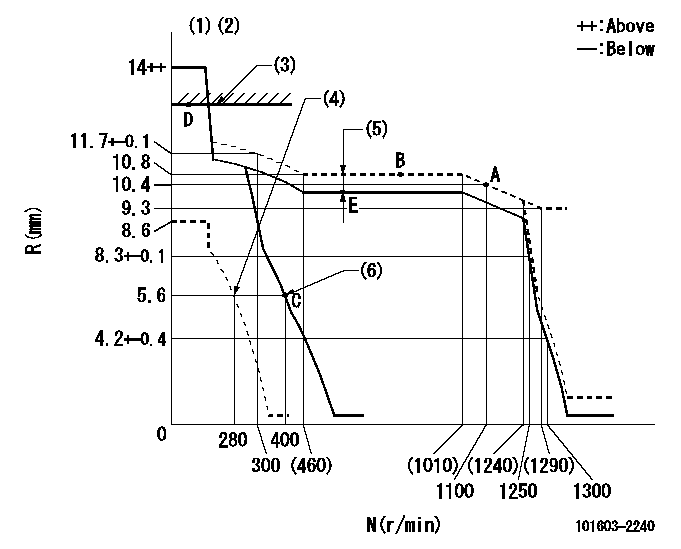

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Boost compensator stroke: BCL

(6)Main spring setting

----------

K=12 BCL=0.8+-0.1mm

----------

----------

K=12 BCL=0.8+-0.1mm

----------

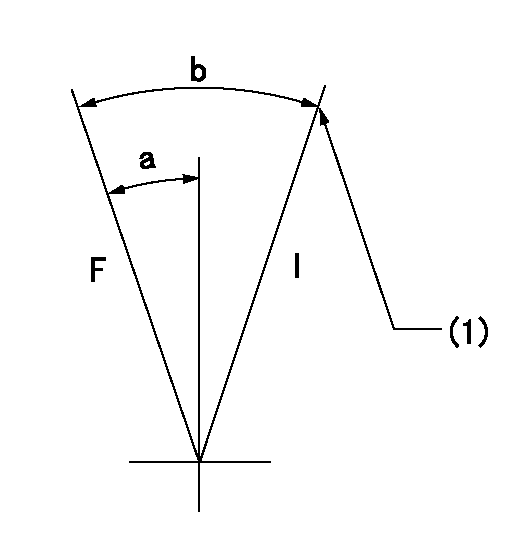

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=17deg+-5deg b=36deg+-5deg

----------

----------

a=17deg+-5deg b=36deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Pump speed aa and rack position bb (to be sealed at delivery)

----------

aa=0r/min bb=1-0.5mm

----------

a=21deg+-5deg b=(55deg)

----------

aa=0r/min bb=1-0.5mm

----------

a=21deg+-5deg b=(55deg)

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(50deg)

----------

----------

a=(50deg)

Information:

4.236 Engines

(1) Inside diameter of rod for small end bushing ... 38.8938 to 38.9192 mm (1.53125 to 1.53225 in)(2) Outside diameter of bushing for piston pin ... 38.989 to 39.027 mm (1.5350 to 1.5365 in) Inside diameter of bushing for piston pin (after reaming) ... 34.9441 to 34.9631 mm (1.37575 to 1.37650 in)Clearance between small end bushing and piston pin ... 0.0191 to 0.0432 mm (.00075 to .00170 in)(3) Distance between center of piston pin and center of crankshaft bearing ... 219.05 to 219.10 mm (8.624 to 8.626 in)(4) Outside diameter of connecting rod bearing ... 67.221 mm (2.6465 in) Inside diameter of connecting rod bearing (standard) ... 63.520 to 63.548 mm (2.5008 to 2.5019 in)Bearings available for reground (machined) journals of crankshaft with undersize ... 0.25, 0.51 and 0.76 mm (.010, .020 and .030 in)Shell thickness ... 1.836 to 1.844 mm (.0723 to .0726 in)(5) Inside diameter of rod for big end bearing ... 67.208 to 67.221 mm (2.6460 to 2.6465 in)(6) Torque for connecting rod nuts: Cadmium plated nuts (silver color) ... 100 N m (75 lb ft)Phosphated nuts (dull black color) ... 130 N m (95 lb ft)T4.236 Engines

(1) Inside diameter of rod for small end bushing ... 42.0688 to 42.0942 mm (1.65625 to 1.65725 in)(2) Outside diameter of bushing for piston pin ... 42.1577 to 42.1958 mm (1.65975 to 1.66125 in) Inside diameter of bushing for piston pin (after reaming) ... 38.1191 to 38.1381 mm (1.50075 to 1.50150 in)Clearance between small end bushing and piston pin ... 0.0191 to 0.0432 mm (.00075 to .00170 in)(3) Distance between center of piston pin and center of crankshaft bearing ... 219.05 to 219.10 mm (8.624 to 8.626 in)(4) Outside diameter of connecting rod bearing ... 67.221 mm (2.6465 in) Inside diameter of connecting rod bearing (standard) ... 63.520 to 63.548 mm (2.5008 to 2.5019 in)Bearings available for reground (machined) journals of crankshaft with undersize ... 0.25, 0.51 and 0.76 mm (.010, .020 and .030 in)Shell thickness ... 1.836 to 1.844 mm (.0723 to .0726 in)(5) Inside diameter of rod for big end bearing ... 67.208 to 67.221 mm (2.6460 to 2.6465 in)(6) Torque for connecting rod nuts: Cadmium plated nuts (silver color) ... 100 N m (75 lb ft)Phosphated nuts (dull black color) ... 130 N m (95 lb ft)

(1) Inside diameter of rod for small end bushing ... 38.8938 to 38.9192 mm (1.53125 to 1.53225 in)(2) Outside diameter of bushing for piston pin ... 38.989 to 39.027 mm (1.5350 to 1.5365 in) Inside diameter of bushing for piston pin (after reaming) ... 34.9441 to 34.9631 mm (1.37575 to 1.37650 in)Clearance between small end bushing and piston pin ... 0.0191 to 0.0432 mm (.00075 to .00170 in)(3) Distance between center of piston pin and center of crankshaft bearing ... 219.05 to 219.10 mm (8.624 to 8.626 in)(4) Outside diameter of connecting rod bearing ... 67.221 mm (2.6465 in) Inside diameter of connecting rod bearing (standard) ... 63.520 to 63.548 mm (2.5008 to 2.5019 in)Bearings available for reground (machined) journals of crankshaft with undersize ... 0.25, 0.51 and 0.76 mm (.010, .020 and .030 in)Shell thickness ... 1.836 to 1.844 mm (.0723 to .0726 in)(5) Inside diameter of rod for big end bearing ... 67.208 to 67.221 mm (2.6460 to 2.6465 in)(6) Torque for connecting rod nuts: Cadmium plated nuts (silver color) ... 100 N m (75 lb ft)Phosphated nuts (dull black color) ... 130 N m (95 lb ft)T4.236 Engines

(1) Inside diameter of rod for small end bushing ... 42.0688 to 42.0942 mm (1.65625 to 1.65725 in)(2) Outside diameter of bushing for piston pin ... 42.1577 to 42.1958 mm (1.65975 to 1.66125 in) Inside diameter of bushing for piston pin (after reaming) ... 38.1191 to 38.1381 mm (1.50075 to 1.50150 in)Clearance between small end bushing and piston pin ... 0.0191 to 0.0432 mm (.00075 to .00170 in)(3) Distance between center of piston pin and center of crankshaft bearing ... 219.05 to 219.10 mm (8.624 to 8.626 in)(4) Outside diameter of connecting rod bearing ... 67.221 mm (2.6465 in) Inside diameter of connecting rod bearing (standard) ... 63.520 to 63.548 mm (2.5008 to 2.5019 in)Bearings available for reground (machined) journals of crankshaft with undersize ... 0.25, 0.51 and 0.76 mm (.010, .020 and .030 in)Shell thickness ... 1.836 to 1.844 mm (.0723 to .0726 in)(5) Inside diameter of rod for big end bearing ... 67.208 to 67.221 mm (2.6460 to 2.6465 in)(6) Torque for connecting rod nuts: Cadmium plated nuts (silver color) ... 100 N m (75 lb ft)Phosphated nuts (dull black color) ... 130 N m (95 lb ft)