Information injection-pump assembly

BOSCH

9 400 615 039

9400615039

ZEXEL

101603-2092

1016032092

HINO

220204400A

220204400a

Rating:

Service parts 101603-2092 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

236002710A

12.

Open Pre:MPa(Kqf/cm2)

17.7{180}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 615 039

9400615039

ZEXEL

101603-2092

1016032092

HINO

220204400A

220204400a

Zexel num

Bosch num

Firm num

Name

101603-2092

9 400 615 039

220204400A HINO

INJECTION-PUMP ASSEMBLY

H07C-T * K

H07C-T * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-0920

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

4.8

4.77

4.83

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

A

Rack position

11.9

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

124.5

123

126

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

33.3

33.3

Boost pressure

mmHg

250

250

Injection quantity adjustment_02

Adjusting point

-

Rack position

6.4+-0.5

Pump speed

r/min

450

450

450

Average injection quantity

mm3/st.

10

9

11

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

130

130

140

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

800

800

800

Rack position

R1-1.4

Boost pressure

kPa

4.7

2

7.4

Boost pressure

mmHg

35

15

55

Boost compensator adjustment_02

Pump speed

r/min

800

800

800

Rack position

R1(11.9)

Boost pressure

kPa

20

13.3

26.7

Boost pressure

mmHg

150

100

200

Timer adjustment

Pump speed

r/min

850--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

800

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1050

Advance angle

deg.

2

1.5

2.5

Remarks

Finish

Finish

Test data Ex:

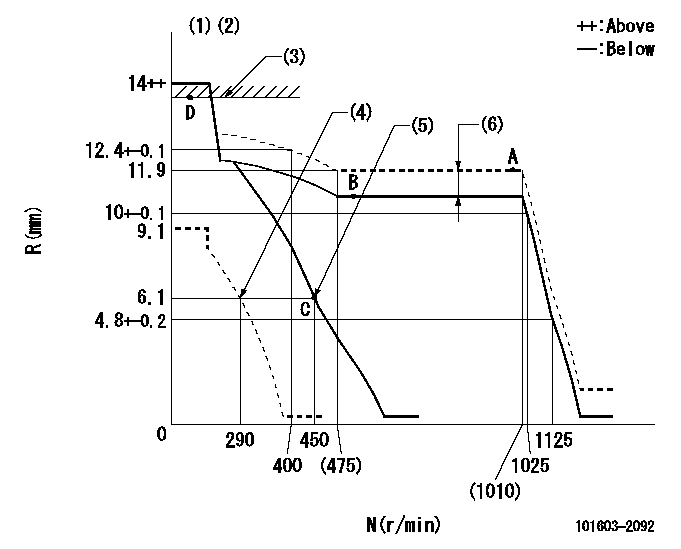

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Main spring setting

(6)Boost compensator stroke: BCL

----------

K=14 BCL=1.4+-0.1mm

----------

----------

K=14 BCL=1.4+-0.1mm

----------

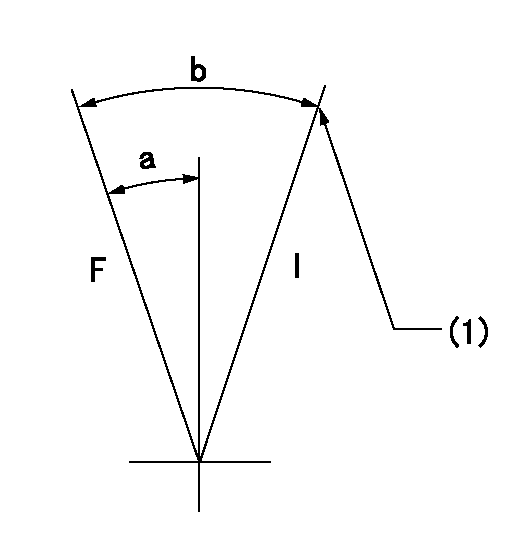

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=10deg+-5deg b=25deg+-5deg

----------

----------

a=10deg+-5deg b=25deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Pump speed aa and rack position bb (to be sealed at delivery)

(2)Normal

----------

aa=0r/min bb=1-0.5mm

----------

a=21deg+-5deg b=(55deg)

----------

aa=0r/min bb=1-0.5mm

----------

a=21deg+-5deg b=(55deg)

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(50deg)

----------

----------

a=(50deg)

Information:

Crankshaft Grinding Specifications

The dimensions and finish for grinding crankshafts are as follows:Diameter (A) for connecting rod bearing journals is;.010 in. (0.25 mm) Undersize ... 2.7396 .0006 in.(69.586 0.015 mm).020 in. (0.51 mm) Undersize ... 2.7296 .0006 in.(69.332 0.015 mm).050 in. (1.27 mm) Undersize ... 2.6996 .0006 in.(68.570 0.015 mm)Surface finish must be 10 micro inches (0.25 micrometers) or less.Radius (B) must be .100 .010 in. (2.54 0.25 mm).Surface finish must be 63 micro inches (1.6 micrometers) or less.The radius must blend smoothly with the newly machined journals.

DIMENSIONS FOR GRINDING

A. Diameter of connecting rod bearing journals. B. Radius on connecting rod bearing journals. C. Width to grind journals for the connecting rods. D. Diameter of main bearing journals. E. Radius on main bearing journals. F. Width to grind journals for the main bearings.Width (C) is 2.314 .003 in. (58.77 0.08 mm)Diameter (D) for main bearing journals is:.010 in. (0.25 mm) Undersize ... 3.4895 .0006 in.(88.633 0.015 mm).020 in. (0.51 mm) Undersize ... 3.4795 .0006 in.(88.379 0.015 mm).050 in. (1.27 mm) Undersize ... 3.4495 .0006 in.(87.617 0.015 mm)Surface finish must be 10 micro inches (0.25 micrometers) or less.Radius (E) must be .095 .010 in. (2.41 0.25 mm)Surface finish must be 63 micro inches (1.6 micrometers) or less.The radius must blend smoothly with the newly machined journals.Width (F) is 1.258 .002 in. (31.95 0.05 mm) for number 4 main bearing journal. Surface finish on the thrust faces of the number 4 main must be 18 micro inches (0.45 micrometers) or less.Width (F) is 1.268 + .020 - .010 in. (32.21 + 0.51 - 0.25 mm) for number 2, 3, and 5 main bearing journals.There is no width (F) for number 1 main bearing journal.When grinding a crankshaft, no material can be removed from the crankshaft webs or counterweights.Crankshaft Gear Removal

Remove the gear using an 8B7548 Push Puller, 8B7551 Bearing Pulling Attachment, 8B75621 Step Plate, and 8H684 Ratchet Box Wrench.

PULLING CRANKSHAFT GEARThe 1P820 Hydraulic Puller Group can also be used to pull gear from crankshaft. Tools required are 1P820 Hydraulic Puller Group, 8B7551 Bearing Pulling Attachment, 8B7549 Puller legs (two), 8B7561 Step Plate, 3H465 Plate (four), 1B4207 Nut (two), and 5P3100 Pump Group.

USING HYDRAULIC PULLERCrankshaft Gear Installation

1. Install the key in keyway of crankshaft. Remove all burrs from key and keyway inside of crankshaft gear.2. Heat gear to 500°F (260°C) maximum.3. Install gear on crankshaft with timing mark on gear facing front of crankshaft.Crankshaft Front Oil Seal Removal

Remove the crankshaft front pulley. Use the 1P3075 Puller Group to remove the crankshaft front oil seal.

REMOVING FRONT OIL SEAL (Typical Example)Remove Crankshaft Rear Seal And Wear Sleeve

Remove the crankshaft rear oil seal with the 1P3075 Puller Group.

REMOVING REAR OIL SEALInstall a 5P7338 Distorter Ring from the 5P7318 Wear Sleeve Distorter Group, in the rear seal bore.

REMOVING REAR WEAR SLEEVE (Typical Example)Install 5P7312 Distorter between distorter ring and wear sleeve. Turn the distorter until the

The dimensions and finish for grinding crankshafts are as follows:Diameter (A) for connecting rod bearing journals is;.010 in. (0.25 mm) Undersize ... 2.7396 .0006 in.(69.586 0.015 mm).020 in. (0.51 mm) Undersize ... 2.7296 .0006 in.(69.332 0.015 mm).050 in. (1.27 mm) Undersize ... 2.6996 .0006 in.(68.570 0.015 mm)Surface finish must be 10 micro inches (0.25 micrometers) or less.Radius (B) must be .100 .010 in. (2.54 0.25 mm).Surface finish must be 63 micro inches (1.6 micrometers) or less.The radius must blend smoothly with the newly machined journals.

DIMENSIONS FOR GRINDING

A. Diameter of connecting rod bearing journals. B. Radius on connecting rod bearing journals. C. Width to grind journals for the connecting rods. D. Diameter of main bearing journals. E. Radius on main bearing journals. F. Width to grind journals for the main bearings.Width (C) is 2.314 .003 in. (58.77 0.08 mm)Diameter (D) for main bearing journals is:.010 in. (0.25 mm) Undersize ... 3.4895 .0006 in.(88.633 0.015 mm).020 in. (0.51 mm) Undersize ... 3.4795 .0006 in.(88.379 0.015 mm).050 in. (1.27 mm) Undersize ... 3.4495 .0006 in.(87.617 0.015 mm)Surface finish must be 10 micro inches (0.25 micrometers) or less.Radius (E) must be .095 .010 in. (2.41 0.25 mm)Surface finish must be 63 micro inches (1.6 micrometers) or less.The radius must blend smoothly with the newly machined journals.Width (F) is 1.258 .002 in. (31.95 0.05 mm) for number 4 main bearing journal. Surface finish on the thrust faces of the number 4 main must be 18 micro inches (0.45 micrometers) or less.Width (F) is 1.268 + .020 - .010 in. (32.21 + 0.51 - 0.25 mm) for number 2, 3, and 5 main bearing journals.There is no width (F) for number 1 main bearing journal.When grinding a crankshaft, no material can be removed from the crankshaft webs or counterweights.Crankshaft Gear Removal

Remove the gear using an 8B7548 Push Puller, 8B7551 Bearing Pulling Attachment, 8B75621 Step Plate, and 8H684 Ratchet Box Wrench.

PULLING CRANKSHAFT GEARThe 1P820 Hydraulic Puller Group can also be used to pull gear from crankshaft. Tools required are 1P820 Hydraulic Puller Group, 8B7551 Bearing Pulling Attachment, 8B7549 Puller legs (two), 8B7561 Step Plate, 3H465 Plate (four), 1B4207 Nut (two), and 5P3100 Pump Group.

USING HYDRAULIC PULLERCrankshaft Gear Installation

1. Install the key in keyway of crankshaft. Remove all burrs from key and keyway inside of crankshaft gear.2. Heat gear to 500°F (260°C) maximum.3. Install gear on crankshaft with timing mark on gear facing front of crankshaft.Crankshaft Front Oil Seal Removal

Remove the crankshaft front pulley. Use the 1P3075 Puller Group to remove the crankshaft front oil seal.

REMOVING FRONT OIL SEAL (Typical Example)Remove Crankshaft Rear Seal And Wear Sleeve

Remove the crankshaft rear oil seal with the 1P3075 Puller Group.

REMOVING REAR OIL SEALInstall a 5P7338 Distorter Ring from the 5P7318 Wear Sleeve Distorter Group, in the rear seal bore.

REMOVING REAR WEAR SLEEVE (Typical Example)Install 5P7312 Distorter between distorter ring and wear sleeve. Turn the distorter until the

Have questions with 101603-2092?

Group cross 101603-2092 ZEXEL

Hino

Hino

Hino

101603-2092

9 400 615 039

220204400A

INJECTION-PUMP ASSEMBLY

H07C-T

H07C-T