Information injection-pump assembly

ZEXEL

101603-2033

1016032033

HINO

220204122A

220204122a

Rating:

Service parts 101603-2033 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

23600-2490A

12.

Open Pre:MPa(Kqf/cm2)

19.6{200}

15.

NOZZLE SET

Cross reference number

ZEXEL

101603-2033

1016032033

HINO

220204122A

220204122a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-0920

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

4.8

4.77

4.83

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

A

Rack position

11.6

Pump speed

r/min

1050

1050

1050

Average injection quantity

mm3/st.

117

115.5

118.5

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

35.3

35.3

Boost pressure

mmHg

265

265

Injection quantity adjustment_02

Adjusting point

-

Rack position

6.2+-0.5

Pump speed

r/min

430

430

430

Average injection quantity

mm3/st.

10

9

11

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

140

140

150

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

800

800

800

Rack position

R1-1.2

Boost pressure

kPa

8.7

6

11.4

Boost pressure

mmHg

65

45

85

Boost compensator adjustment_02

Pump speed

r/min

800

800

800

Rack position

R1(11.6)

Boost pressure

kPa

22

15.3

28.7

Boost pressure

mmHg

165

115

215

Timer adjustment

Pump speed

r/min

850--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

800

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1050

Advance angle

deg.

2

1.5

2.5

Remarks

Finish

Finish

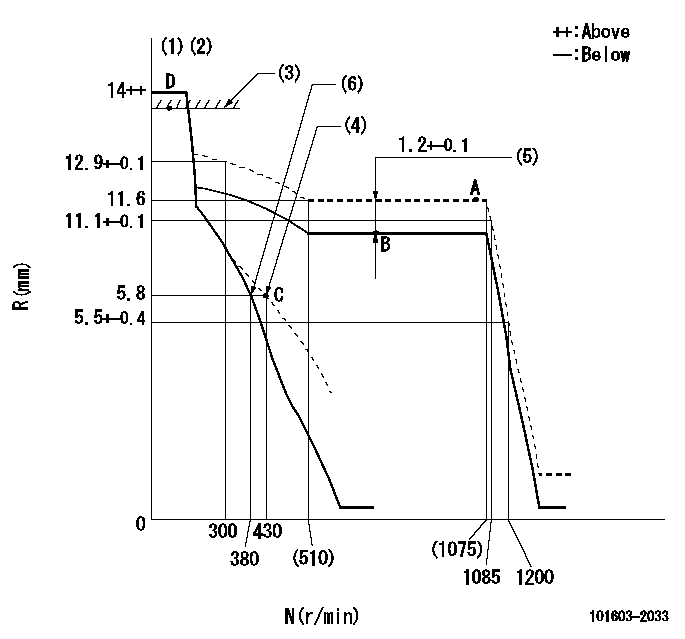

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Boost compensator stroke

(6)Main spring setting

----------

K=16

----------

----------

K=16

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=16deg+-5deg b=28deg+-5deg

----------

----------

a=16deg+-5deg b=28deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Speed = aa, rack position = bb (sealed at shipping)

(2)Normal

----------

aa=0r/min bb=1-0.5mm

----------

a=21deg+-5deg b=(55deg)

----------

aa=0r/min bb=1-0.5mm

----------

a=21deg+-5deg b=(55deg)

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(50deg)

----------

----------

a=(50deg)

Information:

Power Plug To Chassis Harness

Connect 777-PU wire to 777-PU wire on chassis harness.Starter Connections

The connector with the plug in Loc. 3, connects to the bottom starter. The connector without the plug in Loc. 3, goes to the top starter.Air Conditioner (Attachment).

8C9677 Harness Assembly1. Install 8C9677 Harness Assembly to the air conditioner (513-OR and 200-BK).2. Remove plug housing from the EUI engine harness and connect the 2 pin sure seal breakout to 8C9677 Air Conditioner Harness Assembly.Steering Flow Switch.

Connect the 2 pin sure seal breakout to the steering flow switch.Ether System

* Trucks equipped with auto ether system with Multi-Point Oil Pressure Sensing perform the following steps:

8X5415 Wire AssemblyRemove the code plug installed in the chassis auto ether harness on top of the left fore-aft beam near the cab and replace it with 8X5415 Wire Assembly. This disables the multi-point oil pressure function.Remove the engine oil pressure sensor control and its hardware on the right rear of the engine. It will be replaced by the oil pressure sensor for the EUI system.* Trucks with auto ether system where the ether coolant sensor is located in the water regulator housing on the left side of the engine perform the following steps: If the truck has the ether coolant sensor in location (A), the new EUI cover (7E5326) must be reworkedThe bottom right port (B) must be changed to No. 6 Port. Drill and tape for (9/16-18-2B threads).Move the ether coolant sensor to location (B), new No. Port 6. Relocate the connector clip to the lower right bolt of the cover if necessary to retain connection.Tachograph Group

8X8529 Tachometer Group (1) 4N3695 Cable Assembly. (2) Two 338248 Clips. (3) 5M3062 Bolt. (4) 8T4896 Washer.1. Install the 8X8529 Tachometer Drive Group as shown in the illustration above.Tighten the tach cable to 11.3 1.8 N m (100.0 15.9 lb in) at the engine end and 5.7 0.9 N m (50.4 8.0 lb in) at the cab end.2. This completes the EUI retro-fit installation.3. Clean and paint all welded areas.4. Secure all harnesses and wires with tie wraps.5. Check all areas that were modified or changed.6. Connect the batteries.Description Of New Lamps And Switches On New Dash Plate

* CHECK ENGINE LAMP (1)This lamp is used to indicate when a problem exists in the engines electronic control systemThe indicator will come on when the start switch is in the ON position and the engine is not operating. The lamp will stay on approximately 5 seconds, then go out.This lamp is also used to read diagnostic flash codes in conjunction with the diagnostic enable switch.* AIR FILTER RESTRICTION LAMP (2)This lamp indicates that the engine air intake filters are plugged.If the indicator comes on, service the filters that day.* ENGINE OVERSPEED LAMP (3)This lamp indicates the engine rpm is too high. The engine overspeed alarm will sound also when the engine is exceeding maximum allowable limit for safe operation. The lamp and alarm will remain ON as long as the engine is overspeeding.* THROTTLE

Connect 777-PU wire to 777-PU wire on chassis harness.Starter Connections

The connector with the plug in Loc. 3, connects to the bottom starter. The connector without the plug in Loc. 3, goes to the top starter.Air Conditioner (Attachment).

8C9677 Harness Assembly1. Install 8C9677 Harness Assembly to the air conditioner (513-OR and 200-BK).2. Remove plug housing from the EUI engine harness and connect the 2 pin sure seal breakout to 8C9677 Air Conditioner Harness Assembly.Steering Flow Switch.

Connect the 2 pin sure seal breakout to the steering flow switch.Ether System

* Trucks equipped with auto ether system with Multi-Point Oil Pressure Sensing perform the following steps:

8X5415 Wire AssemblyRemove the code plug installed in the chassis auto ether harness on top of the left fore-aft beam near the cab and replace it with 8X5415 Wire Assembly. This disables the multi-point oil pressure function.Remove the engine oil pressure sensor control and its hardware on the right rear of the engine. It will be replaced by the oil pressure sensor for the EUI system.* Trucks with auto ether system where the ether coolant sensor is located in the water regulator housing on the left side of the engine perform the following steps: If the truck has the ether coolant sensor in location (A), the new EUI cover (7E5326) must be reworkedThe bottom right port (B) must be changed to No. 6 Port. Drill and tape for (9/16-18-2B threads).Move the ether coolant sensor to location (B), new No. Port 6. Relocate the connector clip to the lower right bolt of the cover if necessary to retain connection.Tachograph Group

8X8529 Tachometer Group (1) 4N3695 Cable Assembly. (2) Two 338248 Clips. (3) 5M3062 Bolt. (4) 8T4896 Washer.1. Install the 8X8529 Tachometer Drive Group as shown in the illustration above.Tighten the tach cable to 11.3 1.8 N m (100.0 15.9 lb in) at the engine end and 5.7 0.9 N m (50.4 8.0 lb in) at the cab end.2. This completes the EUI retro-fit installation.3. Clean and paint all welded areas.4. Secure all harnesses and wires with tie wraps.5. Check all areas that were modified or changed.6. Connect the batteries.Description Of New Lamps And Switches On New Dash Plate

* CHECK ENGINE LAMP (1)This lamp is used to indicate when a problem exists in the engines electronic control systemThe indicator will come on when the start switch is in the ON position and the engine is not operating. The lamp will stay on approximately 5 seconds, then go out.This lamp is also used to read diagnostic flash codes in conjunction with the diagnostic enable switch.* AIR FILTER RESTRICTION LAMP (2)This lamp indicates that the engine air intake filters are plugged.If the indicator comes on, service the filters that day.* ENGINE OVERSPEED LAMP (3)This lamp indicates the engine rpm is too high. The engine overspeed alarm will sound also when the engine is exceeding maximum allowable limit for safe operation. The lamp and alarm will remain ON as long as the engine is overspeeding.* THROTTLE