Information injection-pump assembly

ZEXEL

101603-2032

1016032032

HINO

220204121A

220204121a

Rating:

Service parts 101603-2032 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

23600-2490A

12.

Open Pre:MPa(Kqf/cm2)

19.6{200}

15.

NOZZLE SET

Cross reference number

ZEXEL

101603-2032

1016032032

HINO

220204121A

220204121a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-0920

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

4.8

4.77

4.83

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

A

Rack position

11.6

Pump speed

r/min

1050

1050

1050

Average injection quantity

mm3/st.

117

115.5

118.5

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

35.3

35.3

Boost pressure

mmHg

265

265

Injection quantity adjustment_02

Adjusting point

-

Rack position

6.2

Pump speed

r/min

430

430

430

Average injection quantity

mm3/st.

10

9

11

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

140

140

150

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

800

800

800

Rack position

R1-1.2

Boost pressure

kPa

8.7

6

11.4

Boost pressure

mmHg

65

45

85

Boost compensator adjustment_02

Pump speed

r/min

800

800

800

Rack position

R1(11.6)

Boost pressure

kPa

22

15.3

28.7

Boost pressure

mmHg

165

115

215

Timer adjustment

Pump speed

r/min

850--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

800

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1050

Advance angle

deg.

2

1.5

2.5

Remarks

Finish

Finish

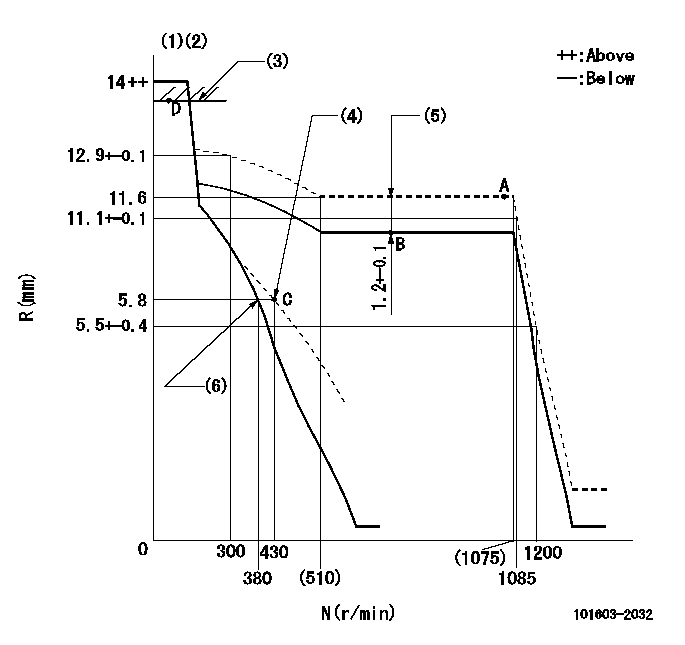

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Boost compensator stroke

(6)Main spring setting

----------

K=16

----------

----------

K=16

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=16deg+-5deg b=28deg+-5deg

----------

----------

a=16deg+-5deg b=28deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Speed = aa, rack position = bb (sealed at shipping)

----------

aa=0r/min bb=1-0.5mm

----------

a=21deg+-5deg b=(55deg)

----------

aa=0r/min bb=1-0.5mm

----------

a=21deg+-5deg b=(55deg)

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(50deg)

----------

----------

a=(50deg)

Information:

2. Locate wire 405-GY on the main cab harness near the connector exiting the cab wall on the right hand side, as shown by arrow.Cut this wire close to the connector. Splice it and the wire just assembled using an 8S4626 Splice. Be sure to splice to the portion of the wire that goes into the cab harness.3. Connect the 7N9738 Housing to the two pin connector on the 8X9862 Harness Assembly (housing containing 405-GY). Clip with a 3T3048 Clip Assembly.Installation of 8X8384 Ether (Chassis) Wiring Harness

The 8X7433 Chassis Harness called out in the AEIS Special Instruction, is replaced with 8X8384 Chassis Harness.Follow the installation procedure outlined in the AEIS Special Instruction for the 8X7433 Harness Assembly. Be sure to use the new 8X8382 Wire Assembly for the harness code plug.Installation of 8X8385 Ether (Engine) Wiring Harness

The 8X7107 Engine Harness on the AEIS is replaced with 8X8385 Harness Assembly.Follow the installation procedure outlined in the AEIS Special Instruction for the 8X7107 Harness Assembly. In addition, the following steps need to be performed. 1. Route the end of the harness with the 8T8732 Receptacle to the 3E3530 Electronic Control Group [oil pressure sensor] (2), installed at the right rear of the engine as shown.2. Connect the three pin receptacle to the connector on the 3E3530 Electronic Control Group (2) and clip into the 9X3495 Clip Assembly (7) installed earlier. Use 3S2093 Straps to loosely secure the harness to the top rear of the engine as shown.3. Remove the 8W3048 Harness Assembly that is connected to the remaining 6T7663 Oil Pressure Switch (9) and was connected to the 6T7663 Oil Pressure Switch that was removed.4. Connect an 8X8337 Harness Assembly to the one remaining oil pressure switch and reconnect to the engine harness. Clip with the existing clip. DO NOT tighten the straps or clips until all new wiring harnesses have been installed so any repositioning or adjustments can be made as necessary.Checking the Automatic Ether Injection System

* The system check-out will be same as for the AEIS with the following change:"A4" harness code on the 777B (indicates 3508 application) for two seconds.Retrofit to an Existing AEIS System

Necessary Parts

Installation of 3E3778 Ether Control Group

The 3E3778 Control Group is required for the MPPS System.Check the electronic control box installed with the AEIS to see if it is a 3E3778 or a 9X5303 Control Group. If a 9X5303 Control Group is installed, replace it with 3E3778 Control Group and 3E3779 Film.Follow the control box installation instructions outlined in the AEIS installation Special Instruction, SEHS9329. Be sure to install the 8X8386 Wire Assembly between the control and mounting plate. If an MPPS identification film is needed for a language other than English, refer to the following chart for the part number of the film for a specific language. Installation of 3E3530 Electronic Control Group [(PWM) Oil Pressure Sensor]

1. Remove the 6T7663 Oil Pressure Switch and adapter from the turbo oil adapter on the right rear of the engine (switch on bottom port with

The 8X7433 Chassis Harness called out in the AEIS Special Instruction, is replaced with 8X8384 Chassis Harness.Follow the installation procedure outlined in the AEIS Special Instruction for the 8X7433 Harness Assembly. Be sure to use the new 8X8382 Wire Assembly for the harness code plug.Installation of 8X8385 Ether (Engine) Wiring Harness

The 8X7107 Engine Harness on the AEIS is replaced with 8X8385 Harness Assembly.Follow the installation procedure outlined in the AEIS Special Instruction for the 8X7107 Harness Assembly. In addition, the following steps need to be performed. 1. Route the end of the harness with the 8T8732 Receptacle to the 3E3530 Electronic Control Group [oil pressure sensor] (2), installed at the right rear of the engine as shown.2. Connect the three pin receptacle to the connector on the 3E3530 Electronic Control Group (2) and clip into the 9X3495 Clip Assembly (7) installed earlier. Use 3S2093 Straps to loosely secure the harness to the top rear of the engine as shown.3. Remove the 8W3048 Harness Assembly that is connected to the remaining 6T7663 Oil Pressure Switch (9) and was connected to the 6T7663 Oil Pressure Switch that was removed.4. Connect an 8X8337 Harness Assembly to the one remaining oil pressure switch and reconnect to the engine harness. Clip with the existing clip. DO NOT tighten the straps or clips until all new wiring harnesses have been installed so any repositioning or adjustments can be made as necessary.Checking the Automatic Ether Injection System

* The system check-out will be same as for the AEIS with the following change:"A4" harness code on the 777B (indicates 3508 application) for two seconds.Retrofit to an Existing AEIS System

Necessary Parts

Installation of 3E3778 Ether Control Group

The 3E3778 Control Group is required for the MPPS System.Check the electronic control box installed with the AEIS to see if it is a 3E3778 or a 9X5303 Control Group. If a 9X5303 Control Group is installed, replace it with 3E3778 Control Group and 3E3779 Film.Follow the control box installation instructions outlined in the AEIS installation Special Instruction, SEHS9329. Be sure to install the 8X8386 Wire Assembly between the control and mounting plate. If an MPPS identification film is needed for a language other than English, refer to the following chart for the part number of the film for a specific language. Installation of 3E3530 Electronic Control Group [(PWM) Oil Pressure Sensor]

1. Remove the 6T7663 Oil Pressure Switch and adapter from the turbo oil adapter on the right rear of the engine (switch on bottom port with