Information injection-pump assembly

ZEXEL

101603-1800

1016031800

Rating:

Cross reference number

ZEXEL

101603-1800

1016031800

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5520

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3

2.95

3.05

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

12.1

Pump speed

r/min

800

800

800

Each cylinder's injection qty

mm3/st.

88

85.4

90.6

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

275

275

275

Each cylinder's injection qty

mm3/st.

10.5

9

12

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(12.1)

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

88

87

89

Basic

*

Fixing the lever

*

Boost pressure

kPa

60

60

Boost pressure

mmHg

450

450

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.2

Pump speed

r/min

1450

1450

1450

Average injection quantity

mm3/st.

92

90

94

Fixing the lever

*

Boost pressure

kPa

60

60

Boost pressure

mmHg

450

450

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1-0.7

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

68.5

66.5

70.5

Fixing the lever

*

Boost pressure

kPa

28.7

28.7

28.7

Boost pressure

mmHg

215

215

215

Injection quantity adjustment_06

Adjusting point

I

Rack position

13.9+-0.

5

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

90

70

110

Fixing the lever

*

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

600

600

600

Rack position

R1-1.1

Boost pressure

kPa

19.3

19.3

19.3

Boost pressure

mmHg

145

145

145

Boost compensator adjustment_02

Pump speed

r/min

600

600

600

Rack position

R1-0.7

Boost pressure

kPa

28.7

27.4

30

Boost pressure

mmHg

215

205

225

Boost compensator adjustment_03

Pump speed

r/min

600

600

600

Rack position

R1(12.1)

Boost pressure

kPa

45.3

38.6

52

Boost pressure

mmHg

340

290

390

Timer adjustment

Pump speed

r/min

1250--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1200

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1300

Advance angle

deg.

1.6

1.1

2.1

Timer adjustment_04

Pump speed

r/min

1400

Advance angle

deg.

3.5

3

4

Remarks

Finish

Finish

Test data Ex:

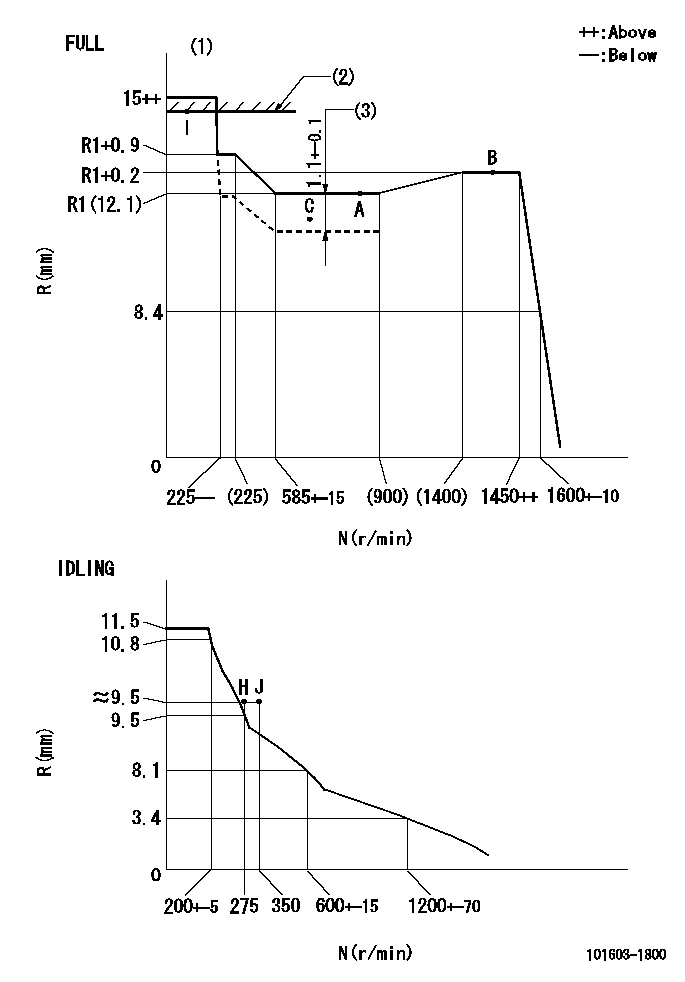

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)RACK LIMIT

(3)Boost compensator stroke

----------

T1=A08

----------

----------

T1=A08

----------

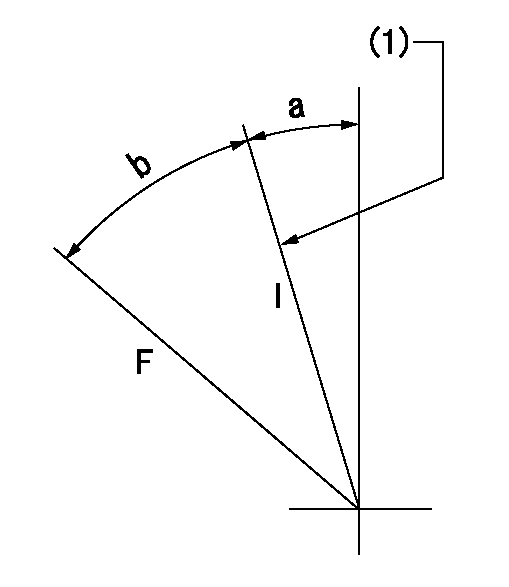

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H'

----------

----------

a=18.5deg+-5deg b=41deg+-3deg

----------

----------

a=18.5deg+-5deg b=41deg+-3deg

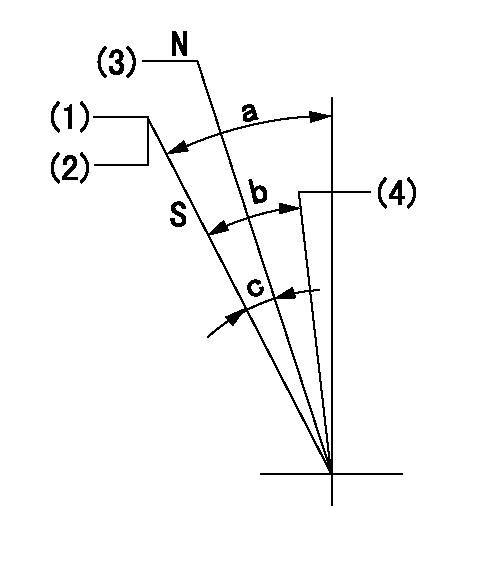

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)At the rated pump speed and rack position aa, set the stopper bolt. (Confirm that there is no injection.)

(2)After setting the stopper bolt, confirm non-injection at speed = bb and rack position = cc. (Speed lever at idle setting.)

(3)Rack position = approximately dd

(4)Free (at delivery)

----------

aa=16mm bb=275r/min cc=(8.5)mm dd=17.4mm

----------

a=38.5deg+-5deg b=(27deg) c=17deg+-5deg

----------

aa=16mm bb=275r/min cc=(8.5)mm dd=17.4mm

----------

a=38.5deg+-5deg b=(27deg) c=17deg+-5deg

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=400+-5r/min Ra=9.2mm

----------

----------

N1=400+-5r/min Ra=9.2mm

----------

Timing setting

(1)Pump vertical direction

(2)Position of timer's tooth at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=16deg

----------

a=(1deg)

----------

aa=16deg

----------

a=(1deg)

Information:

Proper operation and maintenance are key factors in obtaining the maximum life and economy of the engine. Following the directions in this manual will lower operating costs.The time needed for the engine to reach the normal mode of operation is usually less than the time taken for a walk-around-inspection of the engine.After the engine is started and the cold low idle operation is completed, the engine can be operated at rated speed and low power. The engine will reach normal operating temperature faster when operated at rated speed and low power demand than when idled at no load. Typically the engine should be up to operating temperature in a few minutes.Gauges readings should be observed and the data record frequently while the engine is operating. Comparing the data over time will help determine normal readings for each gauge, and help detect abnormal operating developments. Significant changes in the readings should be investigated.Fuel Conservation Practices

The efficiency of your engine can affect the fuel economy. Caterpillar's state-of-the-art design and manufacturing technology provides maximum fuel efficiency in all applications. Follow the recommended operating and maintenance procedures to attain optimum performance for the life of your engine.* Avoid fuel spillage. Fuel expands when warmed, and may overflow from a too-full fuel tank. Inspect fuel lines for leaks, and repair immediately.* Be aware of the heat values of different fuels. Use only recommended fuels.* Avoid unnecessary idling. Shut the engine off rather than idle for long periods of time (unless the temperature is extremely cold).* Observe the air service indicator frequently, and keep the air cleaner elements clean.* Make sure that turbochargers are operating correctly so that the proper air/fuel ratio is maintained. Clean exhaust indicated proper functioning.* Maintain a good electrical system. One bad battery cell will overwork the alternator, consuming excess power and fuel.* Make sure that belts are properly adjusted and in good condition.* Make sure that all air hose connections are tight and do not leak.* Cold engines consume excess fuel. Utilize jacket water and exhaust system heat when possible. Keep radiator fins and water pumps clean and in good repair. Never operate without thermostats. All of these items will help maintain operating temperatures.* Fuel system settings and altitude limits are stamped on the engine Information Plate. If an engine is moved to a higher altitude, settings must be changed by a Caterpillar dealer in order to prevent turbocharger damage and provide maximum engine efficiency. Engines can be operated safely at lower altitudes, but will deliver less horsepower. The fuel settings should be changed by a Caterpillar dealer to obtain the rated horsepower.

The efficiency of your engine can affect the fuel economy. Caterpillar's state-of-the-art design and manufacturing technology provides maximum fuel efficiency in all applications. Follow the recommended operating and maintenance procedures to attain optimum performance for the life of your engine.* Avoid fuel spillage. Fuel expands when warmed, and may overflow from a too-full fuel tank. Inspect fuel lines for leaks, and repair immediately.* Be aware of the heat values of different fuels. Use only recommended fuels.* Avoid unnecessary idling. Shut the engine off rather than idle for long periods of time (unless the temperature is extremely cold).* Observe the air service indicator frequently, and keep the air cleaner elements clean.* Make sure that turbochargers are operating correctly so that the proper air/fuel ratio is maintained. Clean exhaust indicated proper functioning.* Maintain a good electrical system. One bad battery cell will overwork the alternator, consuming excess power and fuel.* Make sure that belts are properly adjusted and in good condition.* Make sure that all air hose connections are tight and do not leak.* Cold engines consume excess fuel. Utilize jacket water and exhaust system heat when possible. Keep radiator fins and water pumps clean and in good repair. Never operate without thermostats. All of these items will help maintain operating temperatures.* Fuel system settings and altitude limits are stamped on the engine Information Plate. If an engine is moved to a higher altitude, settings must be changed by a Caterpillar dealer in order to prevent turbocharger damage and provide maximum engine efficiency. Engines can be operated safely at lower altitudes, but will deliver less horsepower. The fuel settings should be changed by a Caterpillar dealer to obtain the rated horsepower.