Information injection-pump assembly

BOSCH

F 019 Z20 464

f019z20464

ZEXEL

101603-1470

1016031470

MITSUBISHI

ME035835

me035835

Rating:

Service parts 101603-1470 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

22.1(225)

13.

NOZZLE-HOLDER

15.

NOZZLE SET

Cross reference number

BOSCH

F 019 Z20 464

f019z20464

ZEXEL

101603-1470

1016031470

MITSUBISHI

ME035835

me035835

Zexel num

Bosch num

Firm num

Name

101603-1470

F 019 Z20 464

ME035835 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D14 * K 14BE PE6A PE

6D14 * K 14BE PE6A PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.3

3.25

3.35

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

11.5

Pump speed

r/min

850

850

850

Each cylinder's injection qty

mm3/st.

61.5

59.7

63.3

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

9.7+-0.5

Pump speed

r/min

275

275

275

Each cylinder's injection qty

mm3/st.

10.5

9

12

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.5)

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

61.5

60.5

62.5

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1(11.5)

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

65.8

63.1

68.5

Difference in delivery

mm3/st.

5.4

5.4

5.4

Fixing the lever

*

Timer adjustment

Pump speed

r/min

850+-50

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1200

Advance angle

deg.

2.6

2.1

3.1

Timer adjustment_03

Pump speed

r/min

1500

Advance angle

deg.

5.5

5

6

Remarks

Finish

Finish

Test data Ex:

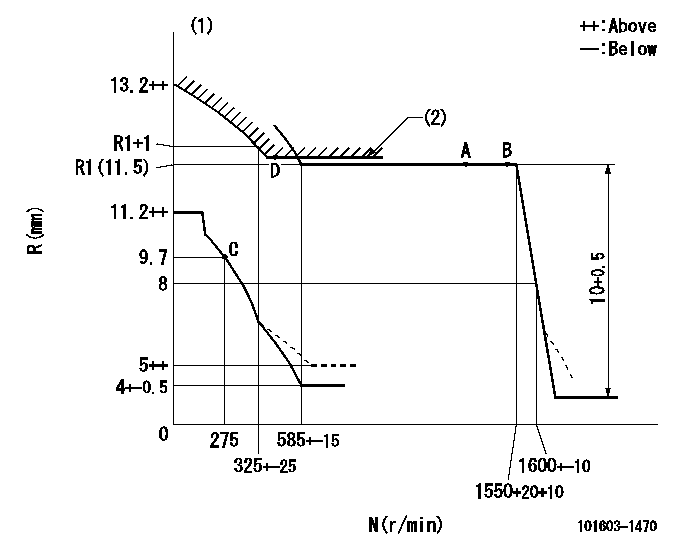

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Beginning of damper spring operation: DL

(2)Excess fuel setting for starting: SXL

----------

DL=6.5-0.2mm SXL=R1(11.5)+1+0.8mm

----------

----------

DL=6.5-0.2mm SXL=R1(11.5)+1+0.8mm

----------

0000000901

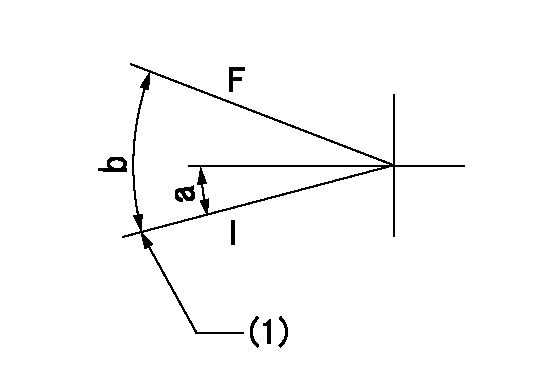

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=17deg+-5deg b=27.5deg+-3deg

----------

----------

a=17deg+-5deg b=27.5deg+-3deg

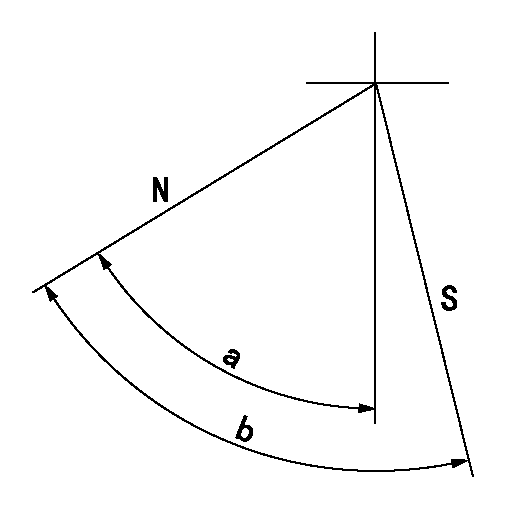

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=60deg+-5deg b=71deg+-5deg

----------

----------

a=60deg+-5deg b=71deg+-5deg

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=410r/min Ra=9.1mm

----------

----------

N1=410r/min Ra=9.1mm

----------

Timing setting

(1)Pump vertical direction

(2)Position of timer's tooth at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=16deg

----------

a=(2deg)

----------

aa=16deg

----------

a=(2deg)

Information:

start by:a) remove fuel injection lines**This operation location is in the ENGINE DISASSEMBLY AND ASSEMBLY section. 1. Disconnect the fuel lines from fuel transfer pump (4) and fuel manifold (3). Disconnect fuel line (2) from the fitting. Disconnect the fuel return line to the tank at (1). Install plugs or caps on all fuel line openings.2. Disconnect drain line (5) from the governor housing. Move the fuel lines and drain line clear of the fuel injection pump housing and governor. 3. Remove bolts (6) that hold the oil manifold to the governor housing. 4. Remove cover (7) from the timing gear cover.5. Remove the bolt and washer that hold the timing gear to the camshaft in the fuel injection pump housing. 6. Install tooling (A) and loosen the timing gear on the camshaft in the fuel injection pump housing.7. Fasten a strap and hoist to the fuel injection pump housing and governor as shown. 8. Remove three nuts (8) and remove the fuel injection pump housing and governor. Weight is 25 kg (56 lb.).Install Fuel Injection Pump Housing And Governor

1. Be sure O-ring seals (1) and (2) are in position on the fuel injection pump housing and governor and put clean oil on the O-ring seals.2. Remove the cover on the fuel injection pump housing and install timing pin (A). Turn the camshaft until timing pin (A) goes in the groove in the camshaft as shown. 3. Fasten a strap and hoist to the fuel injection pump housing and governor and put in position on the timing gear plate and oil manifold (3). Install the three nuts that hold the fuel injection pump housing to the timing gear plate and the two bolts that hold the governor housing to oil manifold (3).

After the fuel injection pump housing and governor are installed on the timing gear plate be sure the rack is free to move. The O-ring seal on the drive end of the fuel injection pump can hold the rack and prevent free movement of the rack. If the rack does not move freely remove the fuel injection pump housing and governor and check the O-ring seal on the drive end of the fuel injection pump housing.

4. Install the bolt and washer (4) as shown to hold the timing gear to the camshaft. Install washer (4) with the larger outside diameter toward the bolt head. Tighten the bolt finger tight only.5. Use the following procedure to put the No. 1 piston at top center on the compression stroke. No. 1 piston at top center (TC) on the compression stroke is the starting point for all timing procedures. The engine is seen from the flywheel end when direction of flywheel rotation is given. Do not turn the flywheel backward. a) Remove plug (5) from the flywheel housing and the breather from the valve cover.b) Turn the flywheel counterclockwise until a 3/8"-16 NC bolt (6) at least 2.5 in. long can be installed in the flywheel through the hole in

1. Be sure O-ring seals (1) and (2) are in position on the fuel injection pump housing and governor and put clean oil on the O-ring seals.2. Remove the cover on the fuel injection pump housing and install timing pin (A). Turn the camshaft until timing pin (A) goes in the groove in the camshaft as shown. 3. Fasten a strap and hoist to the fuel injection pump housing and governor and put in position on the timing gear plate and oil manifold (3). Install the three nuts that hold the fuel injection pump housing to the timing gear plate and the two bolts that hold the governor housing to oil manifold (3).

After the fuel injection pump housing and governor are installed on the timing gear plate be sure the rack is free to move. The O-ring seal on the drive end of the fuel injection pump can hold the rack and prevent free movement of the rack. If the rack does not move freely remove the fuel injection pump housing and governor and check the O-ring seal on the drive end of the fuel injection pump housing.

4. Install the bolt and washer (4) as shown to hold the timing gear to the camshaft. Install washer (4) with the larger outside diameter toward the bolt head. Tighten the bolt finger tight only.5. Use the following procedure to put the No. 1 piston at top center on the compression stroke. No. 1 piston at top center (TC) on the compression stroke is the starting point for all timing procedures. The engine is seen from the flywheel end when direction of flywheel rotation is given. Do not turn the flywheel backward. a) Remove plug (5) from the flywheel housing and the breather from the valve cover.b) Turn the flywheel counterclockwise until a 3/8"-16 NC bolt (6) at least 2.5 in. long can be installed in the flywheel through the hole in

Have questions with 101603-1470?

Group cross 101603-1470 ZEXEL

Mitsubishi

M.Bishi-Hi.-Nag

Mitsubishi

101603-1470

F 019 Z20 464

ME035835

INJECTION-PUMP ASSEMBLY

6D14

6D14