Information injection-pump assembly

ZEXEL

101603-1192

1016031192

M.BISHI-HI.-NAG

EZ40087

ez40087

Rating:

Service parts 101603-1192 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

21.6(220)

15.

NOZZLE SET

Cross reference number

ZEXEL

101603-1192

1016031192

M.BISHI-HI.-NAG

EZ40087

ez40087

Zexel num

Bosch num

Firm num

Name

101603-1192

EZ40087 M.BISHI-HI.-NAG

INJECTION-PUMP ASSEMBLY

6A1 * K

6A1 * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-3720

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.2

4.15

4.25

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

10

Pump speed

r/min

1300

1300

1300

Average injection quantity

mm3/st.

74.2

72.7

75.7

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

7.5+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

10

8.5

11.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

C

Rack position

16.9+-0.

5

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

147

147

157

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

700

Advance angle

deg.

0.5

Timer adjustment_02

Pump speed

r/min

1000

Advance angle

deg.

2.2

1.7

2.7

Timer adjustment_03

Pump speed

r/min

1200

Advance angle

deg.

5

4.5

5.5

Remarks

Finish

Finish

Test data Ex:

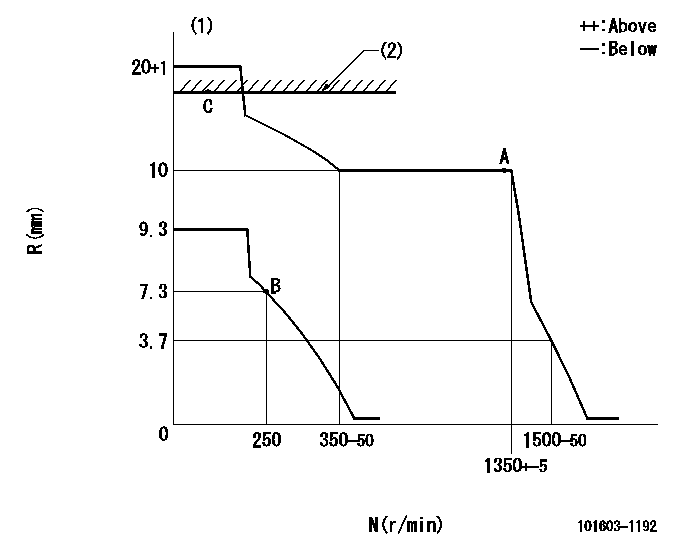

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT

----------

K=15

----------

----------

K=15

----------

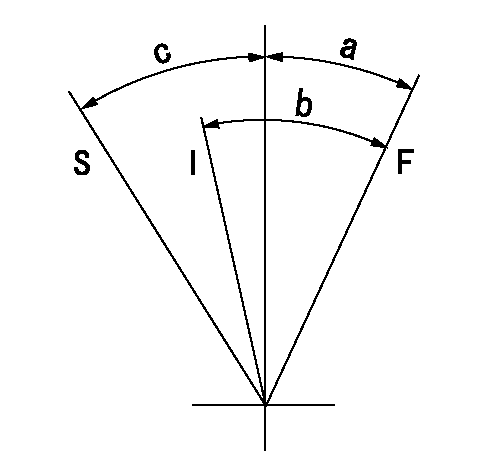

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=24deg+-5deg b=32.5deg+-5deg c=32deg+-3deg

----------

----------

a=24deg+-5deg b=32.5deg+-5deg c=32deg+-3deg

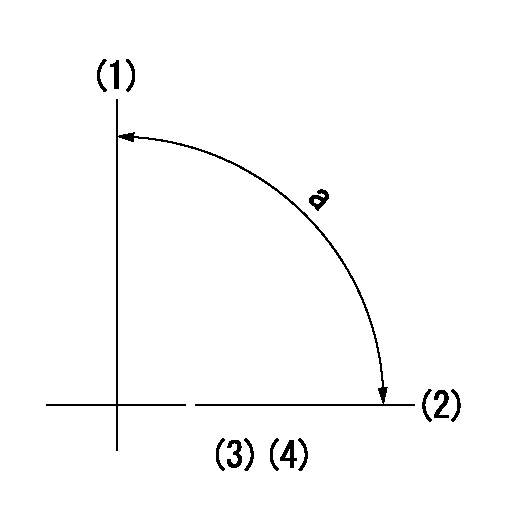

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=43deg+-5deg b=53deg+-5deg

----------

----------

a=43deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear mark '2' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=19deg

----------

a=(90deg)

----------

aa=19deg

----------

a=(90deg)

Information:

Proper operation and maintenance are key factors in obtaining the maximum life and economy of the engine. Following the directions in this manual will lower operating costs.The time needed for the engine to reach the normal mode of operation is usually less than the time taken for a walk-around-inspection of the engine.After the engine is started and the cold low idle operation is completed, the engine can be operated at rated speed and low power. The engine will reach normal operating temperature faster when operated at rated speed and low power demand than when idled at no load. Typically the engine should be up to operating temperature in a few minutes.Governors and Actuators

Your engine may be equipped with a:* full-range governor* Woodward PSG Governor* Woodward 1724 Actuator* Woodward 524 Actuator

PSG Actuator

1724/524 ActuatorWoodward Governors/Actuators are usually electrically operated from a control panel. The application is usually an EPG power generator set. On standby gen sets the governor may be set to operate only at Full Load Speed.Change Engine Speed

If equipped with a control panel, a RAISE/LOWER switch or a speed setting potentiometer is used to adjust the operating speed.Starting, Operating and Stopping Engines Equipped with Control Panels

For all information regarding the generator control panel used for starting, operating and stopping the engine, refer to the Engine Protection Devices Generator Set Control Panel topic in this publication or Caterpillar SR4 Generators and Control Panels, SEBU6150. Additional information and programming instructions are provided in the Service Manual for your specific control panel.Mechanical Governors (If Equipped)

Governor Control LeverYour engine may be equipped with a full-range governor. Most other manufacturers' engines have min-max type governors that only govern at high and low idle to prevent the engine from overspeeding or dying. With the min-max governor, the position of the speed lever determines the amount of fuel delivered to the engine.With the full-range governor, the position of the speed lever sets engine speed and helps hold a constant speed independent of load which makes operation easier.The governor control motor is a 24 volt motor which allows for engine speed control from a remote location through a governor RAISE/LOWER switch. This governor control switch is used with the optional EMCP II. Always increase engine speed to high idle before applying load.For information regarding initial checks and adjustments, refer to the Service Manual or contact your Caterpillar dealer.Driven Equipment Without Load

1. Move the governor control lever to half engine speed.2. Interrupted starts put excessive stress on the drive train and waste fuel. To get the driven equipment in motion, engage the clutch smoothly, with no load on the equipment. This should result in a smooth, easy start without increasing the engine speed above low idle or slipping the clutch. For generator sets, move the governor control to high idle (full load) position (1800 rpm for 60 Hz and 1500 rpm for 50 Hz).3. Apply the load and check the gauges and equipment for proper operation. Begin operating the engine at low load. After normal oil pressure

Your engine may be equipped with a:* full-range governor* Woodward PSG Governor* Woodward 1724 Actuator* Woodward 524 Actuator

PSG Actuator

1724/524 ActuatorWoodward Governors/Actuators are usually electrically operated from a control panel. The application is usually an EPG power generator set. On standby gen sets the governor may be set to operate only at Full Load Speed.Change Engine Speed

If equipped with a control panel, a RAISE/LOWER switch or a speed setting potentiometer is used to adjust the operating speed.Starting, Operating and Stopping Engines Equipped with Control Panels

For all information regarding the generator control panel used for starting, operating and stopping the engine, refer to the Engine Protection Devices Generator Set Control Panel topic in this publication or Caterpillar SR4 Generators and Control Panels, SEBU6150. Additional information and programming instructions are provided in the Service Manual for your specific control panel.Mechanical Governors (If Equipped)

Governor Control LeverYour engine may be equipped with a full-range governor. Most other manufacturers' engines have min-max type governors that only govern at high and low idle to prevent the engine from overspeeding or dying. With the min-max governor, the position of the speed lever determines the amount of fuel delivered to the engine.With the full-range governor, the position of the speed lever sets engine speed and helps hold a constant speed independent of load which makes operation easier.The governor control motor is a 24 volt motor which allows for engine speed control from a remote location through a governor RAISE/LOWER switch. This governor control switch is used with the optional EMCP II. Always increase engine speed to high idle before applying load.For information regarding initial checks and adjustments, refer to the Service Manual or contact your Caterpillar dealer.Driven Equipment Without Load

1. Move the governor control lever to half engine speed.2. Interrupted starts put excessive stress on the drive train and waste fuel. To get the driven equipment in motion, engage the clutch smoothly, with no load on the equipment. This should result in a smooth, easy start without increasing the engine speed above low idle or slipping the clutch. For generator sets, move the governor control to high idle (full load) position (1800 rpm for 60 Hz and 1500 rpm for 50 Hz).3. Apply the load and check the gauges and equipment for proper operation. Begin operating the engine at low load. After normal oil pressure

Have questions with 101603-1192?

Group cross 101603-1192 ZEXEL

Mitsubishi

M.Bishi-Hi.-Nag

101603-1192

EZ40087

INJECTION-PUMP ASSEMBLY

6A1

6A1