Information injection-pump assembly

ZEXEL

101603-0781

1016030781

ISUZU

1156018581

1156018581

Rating:

Cross reference number

ZEXEL

101603-0781

1016030781

ISUZU

1156018581

1156018581

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

12.6

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

76.8

75.2

78.4

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

260

260

260

Average injection quantity

mm3/st.

8.1

6.8

9.4

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(12.6)

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

76.8

75.8

77.8

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

I

Rack position

15.3+-0.

5

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

92

92

100

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

1350--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1300

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1400

Advance angle

deg.

2

1.5

2.5

Timer adjustment_04

Pump speed

r/min

1500

Advance angle

deg.

4.5

4

5

Remarks

Finish

Finish

Test data Ex:

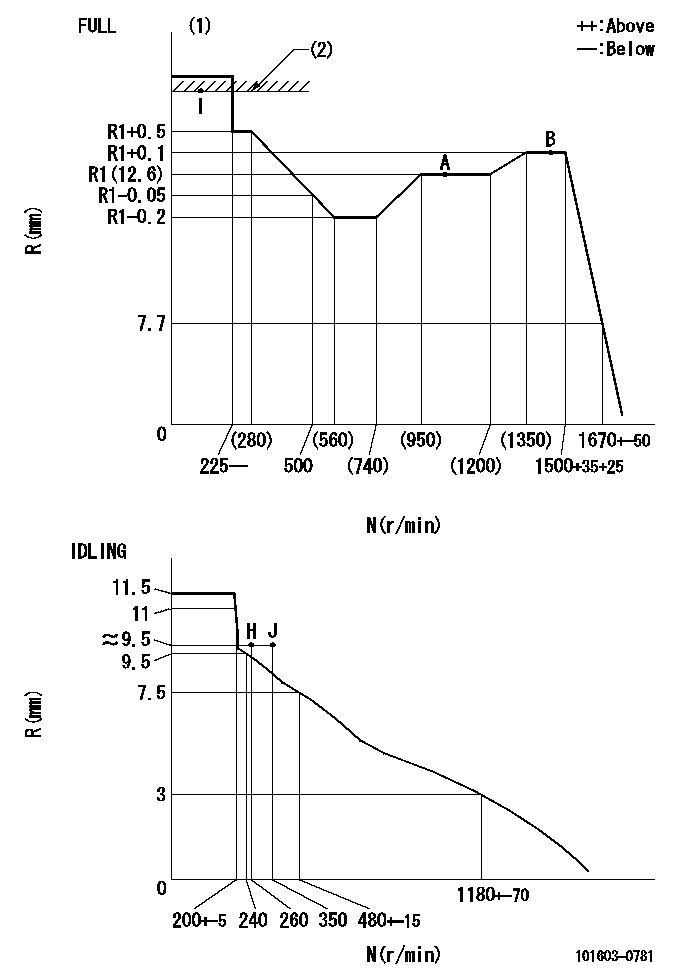

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)RACK LIMIT

----------

T1=C32

----------

----------

T1=C32

----------

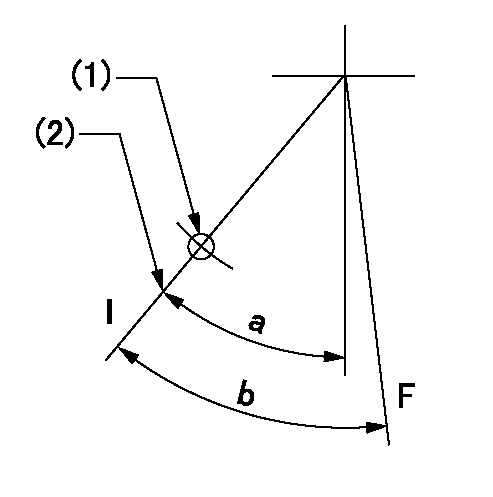

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=35mm

----------

a=42deg+-5deg b=(43deg)+-3deg

----------

aa=35mm

----------

a=42deg+-5deg b=(43deg)+-3deg

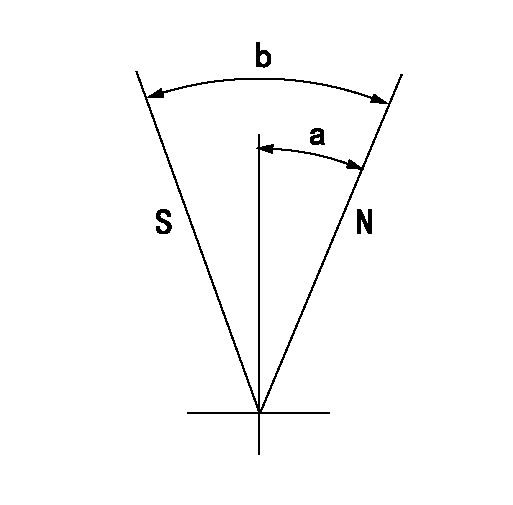

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=25deg+-5deg b=40deg+-5deg

----------

----------

a=25deg+-5deg b=40deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=12deg

----------

a=(60deg)

----------

aa=12deg

----------

a=(60deg)

Information:

When reporting the repair, use "PS61391" as the Part Number and "7777" as the Group Number. Use "96" as Warranty Claim Description Code and use "Z" as the SIMS Description Code.

The information supplied in this service letter may not be valid after the termination date of this program.Do not perform the work outlined in this Service Letter after the termination date without first contacting your Caterpillar product analyst.

TERMINATION DATE

30Jun2020

PROBLEM

The 398-1498 and 463-1678 Fuel Injection Pumps may fail on certain 320D 2 Excavators, equipped with C7.1M Engine. The fuel injection pump failure results in the engine not starting, hard to start, low power, or speed instability.

AFFECTED PRODUCT

Model Identification Number

320D 2 LCA01054-01108

TDZ00816-00829, 888-907, 911-923

PARTS NEEDED

Qty

Part Number Description

3 2323149 WASHER-SEALING

1 4631678 PUMP AS-F INJ

In order to allow equitable parts availability to all participating dealers, please limit your initial parts order to not exceed 2% of dealership population. This is an initial order recommendation only, and the ultimate responsibility for ordering the total number of parts needed to satisfy the program lies with the dealer.

ACTION REQUIRED

Refer REHS3767, Special Instruction, "Inspection of Fuel Injection Pumps on 3054C, C3.3, C4.4 (Mech), and C7.1 (Mech) Engines", to determine if the failure of fuel pump is caused by dirty fuel or customer's maintenance practices, and record facts as specified. Apply this Service Letter program only if the inspection reveals FIP failure that is not attributable to customer's maintenance or use of contaminated / bad fuel.

Remove the existing fuel injection pump, and install a new 463-1678 Fuel Injection Pump Assembly.

Refer to UENR0674, Disassembly and Assembly, C7.1 (Mech) Engines, "Fuel Injection Pump Remove - With Boost Control", and install procedure, in order to complete this Rework Procedure.

SERVICE CLAIM ALLOWANCES

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

0-5000 hrs,

0-24 mo 100.0% 0.0% 0.0% 100.0% 0.0% 0.0%

This is a 8.0-hour job

PARTS DISPOSITION

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.